Introduction of Ferrocement

The construction cost of the homes and the price of the building materials are rising day by day. It is very difficult for a common man to construct an affordable home. The demand for affordable housing is increasing day by day.

The only solution to this problem is to use Ferroconcrete Technology in the Construction Industry. Ferrocement can be used as an alternative to the reinforced cement concrete.

In the Ferro-cement construction, the wire mesh is used, due to which there is a strong bond formation between cement mortar and the meshes.

Ferrocement is a homogeneous structure which has more Tensile strength and compressive strength as compared to Reinforced cement concrete.

In this article, you will get to know about the ferroconcrete definition, properties of Ferrocement, the process of Ferrocement Construction, Advantages and Disadvantages of Ferrocement and the uses of Ferrocement in the construction.

What Is Ferrocement?

- Ferrocement is a composite material which is prepared by using closely spaced one or multiple layers of the meshes and small diameter of rods.

- The ferrocement was developed by the P.L. Nervi, a famous Italian architect in the year 1940. Ferrocement construction is a type of thin wall which is made up of reinforced concrete.

- Ferrocement is an innovative construction material which is readily available because of Its easy construction method it is suitable for construction of various structures.

- The construction of the Ferrocement is generally done by hydraulic cement. The Ferrocement construction has higher strength because of the high cement content. No shuttering is required to cast ferrocement elements.

- There are higher chances of developing shrinkage cracks in the ferrocement because it is made up of water with higher cement content.

- It is necessary that a minimum of 7 days of curing should be done to the ferrocement components to avoid the shrinkage cracks.

- The performance of the Ferro-cement concrete structures depends upon the properties of the reinforcing mesh which is used in the construction.

Properties of Ferrocement

- Ferrocement is a Highly versatile construction material which has different engineering properties such as toughness, strength, fatigue resistance, impact resistance and cracks resistance etc.

- Ferrocement is a very durable, cheap and versatile material used in the construction.

- Ferrocement has less shrinkage and low weight.

- The ferrocement has better impact resistance and punching shear resistance.

- Ferrocement undergoes larger formation before any type of cracks or deflection happens.

- The ferrocement behaves as a homogeneous elastic material within a specific loading limit.

- The ultimate Tensile strength of the ferrocement concrete is up to 34 MPa.

- The modulus of rupture of Ferrocement is up to 55 MPa.

- The Compressive strength of Ferrocement ranges from 28 MPa to 69 MPa.

- Strength of the Ferrocement depends on the quality of the meshes and the quantity of reinforcing bars which are used in the construction.

- Fabricating the Skeletal Framing System

- Applying the Reinforcement Rods and Meshes

- Plaster to the Structure

- Curing

Step 1. Fabricating the Skeletal Framing System

The fabrication is done as per the required shape and size.

Step 2. Applying the Reinforcement Rods and Meshes

Reinforcement which is used in the ferrocement consists of several layers of relatively fine wire mesh which is packed together with or without the reinforced Steel bars.

In the ferrocement construction, the cement Matrix does not crack because all the cracking forces are taken up by the wire mesh reinforcement.

Different types of meshes are available in the market. The commonly used types of wire measures are hexagonal wire mesh, expanded metal mesh and three-dimensional meshes.

Step 3. Plaster to the Structure

In the ferrocement construction, the plastering is done by the mortar and penetration on to the mesh. The mortar is applied in the mesh reinforcement either by the hand or shot through a spray gun. Ferrocement is applied with pressure over the chicken mesh.

It is very necessary that the whole reinforcement mesh should be covered by the ferrocement otherwise there may be chances of corrosion.

Step 4. Curing

Curing is one of the most important parts which provides strength to the structure. It is necessary that the ferrocement components should be a cure for a minimum of 7 days.

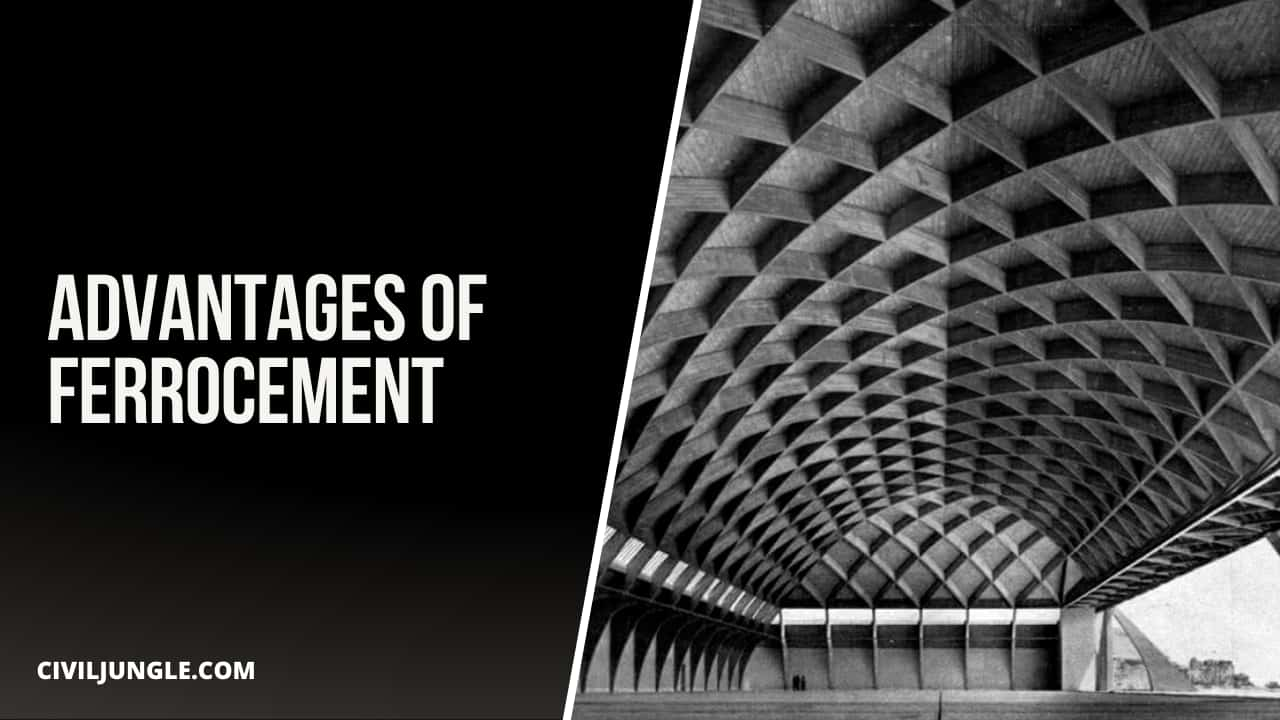

Advantages of Ferrocement

There are different advantages of Ferro cement which are listed below

- Ferrocement is the Best suitable material for the construction of precast units which are easy to transport from one place to another place.

- The construction process of Ferrocement is simple and does not require highly skilled labours.

- Elimination of the formwork for the construction if possible with the use of ferrocement.

- Ferrocement has good fire resistance and impermeability.

- The use of Ferrocement in the construction provides a 30% decrease in the dead load of the structure and 15% savings in the total Steel required for Construction.

- The structures which are made by the ferrocement have less thickness and leads to a significant decrease in the self-weight of the structure.

Disadvantages of Ferrocement

The disadvantages of ferrocement are given below

- The number of labours required for the construction of ferrocement structures is very high.

- In the construction of Ferrocement, the preparation of the framework is very difficult and time-consuming task especially binding the mesh and the Steel rods together.

- The construction of the Ferrocement is labour intensive which makes it costlier for the industrial applications.

- The structures which are constructed with the help of cement are susceptible to puncture due to collision with the sharp objects.

- There may be chances of corrosion of the metal mesh on the reinforcing bars due to incomplete cover of mortar on the reinforcement.

- The ferrocement has low ductility and shear strength.

Uses of Ferrocement

The uses of Ferrocement given are as follows

- Ferrocement is an appropriate material for the boat making.

- Ferrocement is also used in the construction of residential buildings because it saves cement and steel and makes the structure economical.

- Ferro cement is also used in the construction of overhead water tanks for domestic purposes.

- Ferrocement is the best material which is suitable for the construction of benches for garden and parks.

- Ferrocement is also used in the manufacturing of maintenance hole cover.

- Ferrocement is widely used in the maintenance and the repair of the deteriorated structures.

- Ferrocement structures are widely used in rural areas because of its low cost.

- Nowadays Ferrocement is also used in the construction of residential as well as an industrial building.

- Ferrocement is also used in rural energy application which includes biogas digesters, biogas holder incinerators and also panels for collecting solar energy.

- This is the uses of the Ferrocement concrete in the construction of different components.

- The Ferrocement concrete has various unique features due to which it can be used as an alternative for RCC and repair material in the Construction Industry.

Frequently Asked Questions (FAQ) About Ferrocement

What Is Ferrocement?

Ferrocement is a composite material made by using closely spaced layers of wire mesh and small diameter rods, reinforced with cement mortar. It was developed by Italian architect P.L. Nervi in the 1940s.

How Is Ferrocement Different from Reinforced Cement Concrete (Rcc)?

Ferrocement differs from RCC in that it uses a thin, closely spaced mesh and rods, resulting in a homogeneous structure with higher tensile strength and better crack resistance. RCC uses larger reinforcing bars and often requires formwork for construction.

What Are the Key Properties of Ferrocement?

Ferrocement is known for its high tensile and compressive strength, durability, impact resistance, and low shrinkage. It also has good fatigue resistance and punching shear resistance.

What Are the Advantages of Using Ferrocement in Construction?

Advantages include reduced construction weight, lower cost of materials, simple construction process, no need for formwork, good fire resistance, and reduced steel requirements.

Are There Any Disadvantages to Ferrocement?

Disadvantages include high labor requirements, difficulty in framework preparation, potential for corrosion if the reinforcement is not properly covered, and lower ductility and shear strength compared to other materials.

How Is Ferrocement Constructed?

The construction process involves fabricating a skeletal framing system, applying reinforcement rods and meshes, plastering the structure with mortar, and curing for at least 7 days to prevent shrinkage cracks.

What Types of Meshes Are Used in Ferrocement Construction?

Commonly used meshes include hexagonal wire mesh, expanded metal mesh, and three-dimensional meshes.

What Are the Typical Applications of Ferrocement?

Ferrocement is used in boat making, residential buildings, overhead water tanks, garden benches, maintenance hole covers, rural infrastructure, and energy applications like biogas digesters and solar panels.

How Can Ferrocement Structures Be Maintained?

Regular inspection and maintenance are necessary to address any issues such as corrosion or damage. Ferrocement structures can be repaired using similar materials and techniques.

Is Ferrocement a Cost-Effective Construction Material?

Yes, Ferrocement is often more cost-effective due to its low material costs and reduced need for heavy reinforcement. It also offers savings in overall construction weight and material use.