Different Types of Plumbing Traps

Floor Trap or Nahni Trap

A floor trap or Nahni trap is used in the bathroom, kitchen sink, wash basin, wash area, etc places to collect wastewater. As appeared by the name, this kind of trap is situated on the floor.

The diameter of a floor trap or Nahni trap is usually made of 80 millimeters. The depth of the water seal that is provided in it is 50 millimeters.

Its length of it is 310 millimeters with a 30-millimeter diameter at the outlet end and an 80-millimeter minimum at the inlet end. Outside the outlet of a floor trap, the diameter is 73 millimeters.

Floor traps prevent the foul gases which form in the drainage and sewer from entering the house. It builds a water seal and this water seal stops the foul gases from entering the house and causing a bad odor.

Floor traps are available in many materials. You can find floor traps made of UPVC, PVC, and CI. They do not have a vent pipe but at the top of the traps, a removable grating is provided.

The size of the grating is 95 millimeters. The grating contains 8-millimeter holes at the top. These types of traps come in a different variety of sizes, shapes, and outlet conditions.

Many floor traps do not have any water seals. These floor traps have a rough and non-uniform bore. Due to the poor design of floor traps, they are a major source of leakages.

The casting and quality may also be poor in these floor traps. To prevent this and provide a positive joint deal seal P traps are used with multi-inlet traps with connections from the wash basins.

Gully Traps

Before connecting the drainage pipe with the city sewer system a gully trap is provided outside of the building. It also collects wastewater from the wash basin, kitchen sink, bath, and wash area.

The total depth of a heavy cast iron gully trap shall not be less than 30 centimeters or 1 foot. The weight of the cast iron gully trap shall be around 7.25 kg. The weight of the frame is nearly 2.72 kg and the weight of the cover is nearly 4.53 kg.

A gully trap is provided to prevent the foul gases formed in the city sewer system from entering the house. It blocks the gases by the water seal inside it. The water seal is a little deep and the depth is nearly 50 millimeters.

The gully traps also prevent bugs and insects from the sewer system from entering the house. With a minimum water seal of 50 millimeters, the total depth of water shall not be less than 15 centimeters.

Every gully trap should have a cast iron grating of 15 centimeters × 15 centimeters and it must be embedded in the concrete foundation perfectly and in a brick masonry chamber, it must be housed.

Plaster the chamber well and fix one airtight and watertight cover over the frame of inside dimensions of 30 I’m × 30 cm. Gully traps receive sullage from wash basins, kitchen sinks, and baths and they pass it onto the sewing.

If a gully trap is installed then it is unnecessary to install individual traps for kitchen sinks, washbasins, and baths. To prevent choking gully traps need to be cleaned regularly.

P Traps

- This type of trap is utilized with the Orissa pattern Indian water closet.

- P traps are made of either UPV sheet or cast iron.

- P traps also have a water seal which prevents sewer gases from entering.

Q Traps

- The utilization of q traps takes place in the submerged latrine storage room.

- The shape is a little different from S traps.

- Q traps are used in the upper story.

S Traps

- These traps are shaped like the English alphabet ‘S’.

- To fix the water closet of the latrine, these traps are used.

- S traps are used for an outlet through the floor.

Bottle Traps

- Bottle plumbing traps are set to the washbasin, kitchen sinks for collecting squander from those.

- In different types of machines where the apparatus does not have an underlying trap.

Intercepting Traps

- Intercepting traps are used in the interceptor chamber or interceptor manhole. It is utilized at the interception of the building sewer and city sewer.

- Intercepting traps stop from entering foul gases of the sewer system into the building by providing a good water seal.

- The depth of the water seal in intercepting traps is 100 mm. This deep water seal also prevents bugs and insects from entering the house.

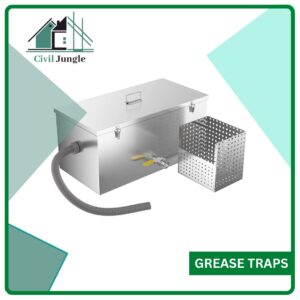

Grease Traps

- To separate grease from liquid and then retain it, grease traps are used.

- These are installed at the waste pipe from one or more fixtures.

What Is a Plumbing Trap?

A plumbing trap is a device that allows waste material to pass through but stops foul gases from entering the house by providing a water seal. These devices are shaped with a bending path. plumbing traps are usually S, Q, P, and J shaped. The most common and most used among these is P shaped.

Sewage creates many foul gases like carbon monoxide, sulfur, methane, etc which are injurious to health. The process of producing these gases in sewers can not be stopped but we can prevent these gases from entering the house by using a plumbing trap.

Frequently Asked Questions (FAQ)

What Is the Primary Function of a Plumbing Trap?

A plumbing trap’s primary function is to allow waste material to pass through while preventing foul gases from entering the house. It achieves this by maintaining a water seal, which blocks the gases produced in sewers or drainage systems.

What Types of Plumbing Traps Are Commonly Used?

Common types of plumbing traps include:

- Floor Trap (Nahni Trap): Used in bathrooms, kitchens, and wash areas to collect wastewater and prevent foul gases from entering the house.

- Gully Trap: Installed outside buildings before connecting to the city sewer system, designed to block sewer gases and prevent insects from entering.

- P Trap: Often used with Indian water closets, made from materials like UPVC or cast iron, featuring a water seal to block sewer gases.

- Q Trap: Used in submerged latrine storage rooms, designed for use in upper stories.

- S Trap: Shaped like the letter ‘S’, used for water closet installations where the outlet is through the floor.

- Bottle Trap: Used under washbasins and kitchen sinks where space is limited, collecting waste and providing a water seal.

- Intercepting Trap: Installed in interceptor chambers or manholes to prevent sewer gases from entering buildings by maintaining a deep water seal.

- Grease Trap: Designed to separate grease from wastewater before it enters the drainage system.

How Does a Floor Trap Differ from a Gully Trap?

A floor trap is typically installed on the floor of bathrooms, kitchens, and other areas to collect wastewater and prevent foul gases. It usually has a water seal depth of 50 millimeters and can be made of materials like UPVC, PVC, or cast iron.

A gully trap, on the other hand, is installed outside buildings, often before connecting to the city sewer system. It prevents sewer gases from entering the house and also blocks insects from entering. It has a deeper water seal (at least 50 millimeters) and is usually made of heavy cast iron.

Why Are P Traps Commonly Used in Plumbing?

P traps are commonly used due to their effective water seal, which prevents sewer gases from entering living spaces. They are typically made from UPVC or cast iron and are often used with Indian water closets.

What Is the Purpose of a Grease Trap?

A grease trap separates grease from wastewater before it enters the main drainage system. It helps prevent grease buildup in pipes, which can lead to blockages and clogs in the plumbing system.

How Often Should Plumbing Traps Be Cleaned?

The frequency of cleaning depends on the type of trap and its usage. For example, gully traps and grease traps should be cleaned regularly to prevent blockages and maintain their effectiveness. Bottle traps under sinks may need less frequent cleaning but should still be checked periodically.

Can a Plumbing Trap Be Installed by a Homeowner, or Is Professional Help Required?

While some simple traps, like bottle traps, might be installed by a homeowner with basic plumbing skills, many traps, especially those involving complex installations like gully or intercepting traps, should be installed by a professional plumber to ensure proper function and compliance with local codes.