What is Tremie Pipe?

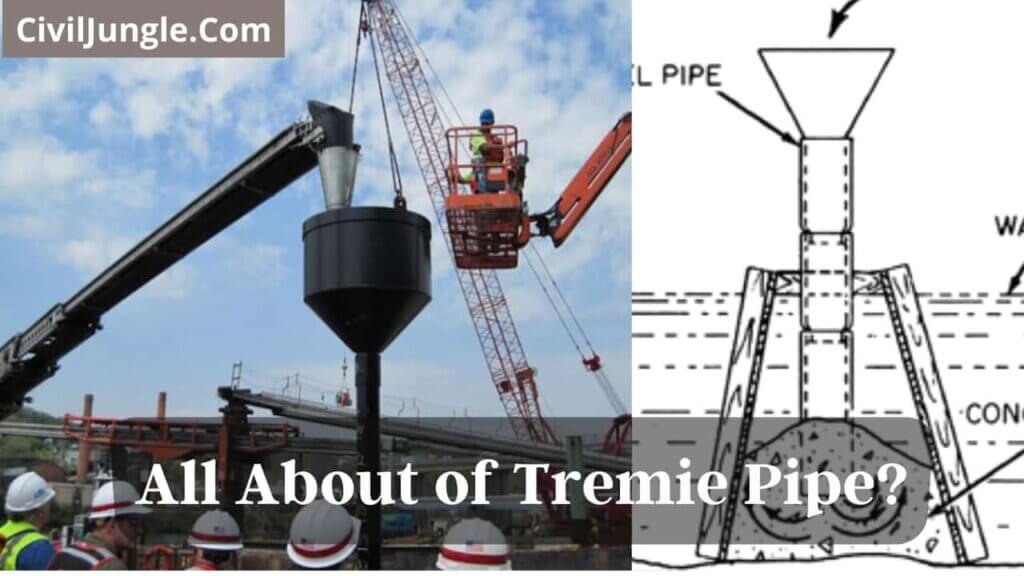

A tremie is a pipe that can be used for pouring concrete below ground level, often underwater. Common applications include piling works, basements, diaphragm walls, caissons, underwater foundations, etc.

A tremie is made of rigid metal or plastic tubes, generally with a diameter ranging from 20 – 30 cm. The time pipe length is 300mm, made of plastic tubes.

A tremie pipe uses to concentrate underwater in a way that concrete is quelling slowly. This procedure will not give an acceptable solution as a particular quantity of washing away of cement is skip to happen.

A dry mixture of cement decent and rough sum is complete in cement bags and, like bagged concrete, is fixed on the bed under the water.

This procedure does not provide acceptable concrete, as the concrete mass cover of clear disperse with the short-lived gunny bags. Tremie pipe procedure of concrete pouring underwater is a proper procedure that spreads worldwide.

Underwater Concrete Mixes

- Cement: ASTM, Type II, 600 lbs. / yd3.

- Coarse aggregate: gravel of 3/4″ max. Length. The total sum by weight is 50-55%.

- Fine aggregate: sand is 45-50% of the total weight of aggregate.

- Pozzolana: ASTM 616 type N or F, 100lbs/yd3.

Underwater Concrete

- Water-cementitious ratio: o.35 to 0.45 by mass

- Fines content: 360 to 500kg/m3

- Water-to-fines ratio: 0.85 to 1.0 by volume

- Sand-to-total content ratio: 45% to 50%.

- Setting time : 5-24 hours

- Slump: 6 ½ inches. +- 1 inch.

Tremie Method of Underwater Concrete

- Underwater concreting using the tremie method is suitable for draining a high quantity of heavy leakage concrete.

- The concrete is displaced to the hopper by further pumping, belt skips.

- Tremie pipe, the top ending jointed to a hoper and bottom ending running drowned in new concrete, is used to locate concrete at the correct position from the hopper at the field.

- The cause to dip the tremie pipe bottom end is to stop combine of both concrete and water.

- Because of mass size, Tremie pipe should have a capable diameter to block the leakage.

- Commonly diameter is 200-300mm aggregate of clear junction for up and down of size.

- The lower end is secured with a plug and chosen below.

- The water keeps the peace at the location where the concrete is running. Later the end is close, and no water will have passed the pipe.

- The concrete must have a 15-20cm slump to dig into the funnel when the total size of the tube covering with concrete, the tremie pipe boost, and a slight jerk given by a tackle and pulley.

- When the line heaves and provides a draw, the lower plug falls because of a load of concrete, and concrete gets released.

- Must take particular heed to this situation to look which the end.

- Tremie pipe continues in the concrete so that no water passes the line from the lower.

- Again concrete is dug over the funnel, and when the total size of the tremie pipe cover with concrete, the tube is again slight boost and given a small jerk.

- Care choose every time to keep the bottom end of the tremie pipe in raised concrete. The concrete of the tremie pipe gets released in that time.

- This process carried out smoothly benefits the concrete does not get damaged by the water omitting the upper end.

- The upper layer is purified to take off the damaged concrete at the end of the entire function.

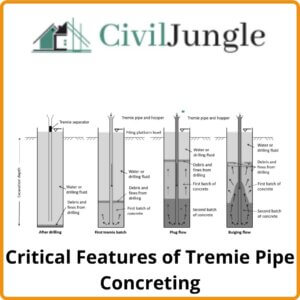

Critical Features of Tremie Pipe Concreting

- At the time of the concrete process, no pumping of water should be allowed; the cement piece, if jointly pumping of water is done.

- Next, the concrete is appropriate, which does not usually need compression.

- The main demerit of underwater concreting is in this process in that a more water ratio needs more consistency which decreases the power of concrete.

- On the other hand, the cementing method of wrapped aggregate is not so usually occupied to location concrete below water.

- The prepared cement mortar cementing is fitted by the pipe, which spreads to the lower aggregate bed.

- The grout power the water out from the gap and employs the place.

- Concrete can locate underwater by the use of pipes and concrete pumps.

- When the whole pipe is covered, the plug eject; the concrete near the bottom end of the line secures the tube.

- The pumping is opposed to the plug’s mass at the bottom end. When the pumping issue need is too high to pass the pressure, the pipe eject, and the process is regular. This method continues since the concrete arrives at a level above water.

Frequently Asked Questions (FAQs)

What Is a Tremie Pipe?

A tremie pipe is a specialized tube used for pouring concrete underwater or below ground level. It is commonly used in construction applications such as piling works, diaphragm walls, caissons, and underwater foundations.

What Materials Are Used to Make Tremie Pipes?

Tremie pipes are typically made of rigid metal or plastic tubes. The diameter of these pipes generally ranges from 20 to 30 cm, and the length can vary depending on the application.

How Does the Tremie Pipe Method Work for Underwater Concreting?

The tremie pipe is used to place concrete underwater by allowing it to flow from the hopper at the top, through the pipe, and into the desired location. The pipe is kept submerged in the concrete to prevent mixing with water and ensure proper placement.

What Is the Recommended Diameter for a Tremie Pipe?

The diameter of a tremie pipe usually ranges from 20 to 30 cm. It should be large enough to prevent clogging and ensure a smooth flow of concrete.

What Are the Key Features of Underwater Concrete Mixes?

Underwater concrete mixes typically include ASTM Type II cement, coarse aggregate (gravel), fine aggregate (sand), and pozzolana. The water-cementitious ratio is generally between 0.35 and 0.45, with specific guidelines for slump and setting time.

How Do You Ensure Proper Placement of Concrete Using a Tremie Pipe?

To ensure proper placement, the tremie pipe must remain submerged in the concrete. Concrete should be poured continuously to avoid segregation and to ensure that the pipe remains filled with concrete at all times.

What Are the Common Challenges When Using a Tremie Pipe?

Challenges include preventing water from mixing with concrete, maintaining a consistent flow of concrete, and dealing with potential clogging of the pipe. Proper technique and monitoring are essential to address these issues.

Can Tremie Pipes Be Used for All Underwater Concrete Applications?

While tremie pipes are suitable for many underwater concrete applications, specific requirements and conditions may vary. It is important to assess the project needs and consult with experts to determine the best approach.

How Do You Handle the End of the Tremie Pipe During Operation?

The lower end of the tremie pipe is kept submerged in concrete to prevent water from entering. When the pipe is filled with concrete, it is slightly lifted and adjusted to ensure continuous flow and avoid water ingress.

What Should Be Done If the Tremie Pipe Becomes Clogged?

If clogging occurs, the pipe may need to be cleaned or cleared. It is important to stop the concrete flow and take necessary measures to remove the obstruction, such as using a cleaning tool or adjusting the flow rate.