Properties of Sand

It can be used as soon as it is obtained from the source. Contains binding content (5-20 per cent), water (5-8 per cent) and a significant amount of organic matter. The moisture content should be preserved for a long time.

Finishing on natural sand moulds is fine. It’s cheaper than most sands. It has less refractoriness. It is used for casting CI and non-ferrous metals. Natural sand moulds can be quickly repaired.

When combined with bentonite, the properties of sand are enhanced and have properties like Synthetic Sand.

1. Physical Properties of Sand

Here the different types of physical proprietors of sand are as follows with full detail.

- Grain Size of Sand

- Grain Shape of Sand

- Shape and Distribution of Sand Grains

- Size Distribution of Sand

a. Grain Size of Sand

The grain shape and scale of the moulding sand determine the overall surface area of the grains found in the unit mass.

Total surface area is defined as a particular surface area. A particular surface provides a rough understanding of the quantity of binder required to coat grains of sand moulding.

Grain size and distribution affects many properties of sand, such as permeability, flowability, refractory properties, surface fineness and strength.

The finer the grains of sand, the finer the entire sand. Fine grain sands offer a good surface finish but have poor permeability.

With the same content of clay, the environmental strength is greater in the context of fine sand than in the context of rough sands.

Solid and evenly graded sand has high permeability, decent reactiveness as well as high flowability. Usually, foundry sand has grain sizes around 0.1 and 1.0 mm.

Fine-grained sands are being used to the importance of ensuring as well as small castings. Large grained sands are being used to produce large castings.

b. Grain Shape of Sand

The shape of the grain is defined in terms of angularity as well as sphericity. The grains of sand range from well rounded, subrounded, angular and also very angular.

Inside each angularity unit, grains can be of a high, medium, or low sphericity. The angularity of sand is measured by visual inspection using a low-power microscope.

The best foundry sands include grains that have been rounded with medium to high sphericity, offering goof flowability and high-intensity permeability at low binder additions.

More angular and lower spherical sands require higher binder additions, lower packing density and poorer flowability.

c. Shape and Distribution of Sand Grains

The texture, size and form of the sand grains are critical for controlling the consistency of the mould. Many of the mould aggregates are mixtures of fresh sand and recycled sand, which comprise not only reclaimed sand but also core sands.

In deciding the scale, shape and distribution of sand grains, it is necessary to note that the grain shape corresponds to the amount of sand surface area and that the distribution of grain size influences the permeability of the mould.

If the sand surface area increases, the volume of bonding content (usually clay and water) must increase if the sand is to be adequately bonded.

As a result, a difference in surface area, possibly due to a change in sand form or the proportion of core sand being retrieved, would result in a related change in the amount of bond required.

Rounded grains have a low surface-area-to-volume ratio and are thus favoured for core processing because they need the least amount of binder.

However, when recycled into the sand moulding system, their form can be disadvantageous if the moulding system usually uses a high percentage of clay and water to allow quick, automatic moulding.

This is because the rounded grains need less sand than the rest of the structure.

Angular sands have the highest surface area (with the exception of sands that crack quickly and contain a significant proportion of small grains and fine sands) and thus require more mulling, bonding and moisture.

The angularity of sand rises with its use when the sand is broken by thermal or mechanical shocks.

The porosity of the mould regulates its permeability, i.e. the capacity of the mould to allow the gasses produced during the spilling to pass through all the mould. The maximum porosity is attributed to grains that are all about the same size.

As the size range widens, there are plenty more particles that are tiny enough just to occupy the gap between large grains. When grains break down by constant recycling, there seem to be smaller grains as well as the porosity of the mould reduces.

Furthermore, if the porosity of a mould is too high, the metal will penetrate sand grains and create a burn-in flaw.

It is also important to balance the delivery of base sand and proceed to screen the sand and then use dust collectors throughout recycling to extract fines and to decide the correct bond addition.

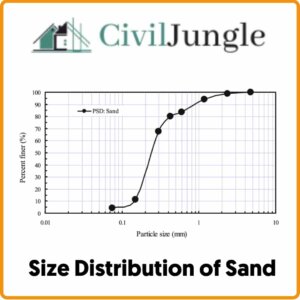

d. Size Distribution of Sand

The size distribution of sand influences the consistency of the casting. Coarse grain sand allows the metal to enter the moulds and cores, giving the castings a weak surface finish.

Fine-grained soils produce a better surface finish but need a higher bonding content and low permeability can cause a gas defects in castings.

2. Chemical Properties of Sand

Here the different types of physical chemicals of sand are as follows with full detail.

- Soil Reaction (PH) of Sand

- Silicate Clay Presence in Sand

- Cation Exchange Capacity (CEC) in Sand

a. Soil Reaction (PH) of Sand

By reference, “PH” is a calculation of the concentration of active hydrogen ions (H+). It is an indicator of the acidity or alkalinity of the soil and is therefore defined as the “soil reaction.”

The pH varies from 0 to 14, for values under 7.0 acid as well as values above 7.0 alkaline.

The pH value of 7 is known to be neutral, where H+ and OH-are equivalent, all at a concentration of 10-7 moles/liter. The pH of 4.0 is ten times more acidic than the pH of 5.0.

The most significant influence of ph in the soil is on ion solubility, and this, in turn, determines microbial growth including plant growth.

The initial ph of 6.0 to 6.8 is suitable for many of these plants as it fits the optimal solubility of the most essential plant nutrients. Few minor elements (e.g. iron) yet most toxic chemicals are much more soluble at reduced PH.

This allows pH management essential for regulating the transport of toxic metals (and possible contaminated groundwater) in soil.

With construction and also an industrial perspective, it is important to decide the pH of the soil mass. The acidic, as well as basic essence of the soil, should be understood for growing healthy crops.

In the other side, in building work, strongly acidic soils would have a bearing on the road’s bitumen stability and detrimental effects on concrete strength. (The salinity of soils can also raise cost of maintenance)

Hydrogen, as well as aluminium, become dominant interchangeable cations in acid soils. The latter would be soluble within acidic conditions, and its reactivity with water (hydrolysis) creates hydrogen ions.

Calcium, as well as magnesium, are simple cations; the relative sum of acidic cations increases as their concentrations increase.

Factors influencing soil pH include parent material, vegetation and atmosphere. Some rocks and sediments contain more acidic soils than others: quartz-rich sandstone is acidic; limestone is alkaline.

Some types of vegetation, especially conifers, produce organic acids that can contribute to lower soil pH values.

In wetlands such as the eastern US, soils begin to become more acidic with time, because runoff washes out essential cations and replaces them with hydrogen.

b. Silicate Clay Presence in Sand

The presence of silicate clay content influences the chemical properties of the soil mass. Clay particles have a wide surface area and are the best materials in the soil mass.

Clay particle increases the reactivity of the soil mass and influences the cohesion of the soil mass by forming compounds with foreign materials.

The assessment of the occurrence of silicate clay is necessary in order to determine the reactivity of the soil mass and its consistency with the mixtures and building materials used in concrete.

c. Cation Exchange Capacity (CEC) in Sand

Any plant nutrients and metals occur in the soil atmosphere as positively charged ions or “cations.”

Among the most important soil cations are hydrogen (H+), aluminium (Al+3), calcium (Ca+2), magnesium (Mg+2) and potassium (K+). Many heavy metals also occur in the soil ecosystem as cations.

Clay and organic matter particles are primarily negatively charged (anions) and have the capacity to keep cations from being “leached” or washed away.

Adsorbed cations are subject to substitution by other cations in a quick, reversible mechanism called cation exchange.

The Cation Exchange Capacity of the soil is indeed an estimate of the maximum of the negative value at a given weight of the sample, or the sum of cations that a given soil sample can carry in an interchangeable shape.

Cations escaping the exchange sites meet the soil particles where they’ll be absorbed by plants, interact with several other soil elements, or transported with runoff water.

The higher the quantity of clay as well as organic matter much higher the Cation Exchange Capacity, while various forms of clay minerals and organic matter may differ in Cation Exchange Capacity.

Cation exchange is an important process in soils for the preservation and delivery of plant nutrients and for the adsorption of pollutants.

It plays an important function in soil wastewater treatment. Sandy soils with low CEC are usually unsuitable for septic systems because they have no adsorptive capability and there is a potential for groundwater.

FAQ: Sand Properties

What Are the Primary Physical Properties of Sand?

The primary physical properties of sand include grain size, grain shape, shape and distribution of sand grains, and size distribution. These properties affect the sand’s permeability, flowability, refractory properties, and overall strength.

How Does Grain Size Affect the Properties of Sand?

Grain size influences the sand’s surface area, permeability, and flowability. Finer grains result in a smoother surface finish but lower permeability, while coarser grains provide better permeability but a rougher surface finish.

What Is the Significance of Grain Shape in Sand?

Grain shape, which includes angularity and sphericity, affects the flowability and binder requirements of sand. Rounded grains are easier to work with and require less binder, while angular grains have higher surface areas and require more binder.

How Does the Shape and Distribution of Sand Grains Impact Mold Consistency?

The texture, size, and form of sand grains are crucial for mold consistency. Proper distribution of grain sizes can influence the permeability and bonding properties of the sand, affecting the quality of the mold.

What Is the Importance of Sand’s Chemical Properties?

Chemical properties such as soil reaction (pH), the presence of silicate clay, and cation exchange capacity (CEC) impact the sand’s reactivity, cohesion, and suitability for various applications. These factors influence the sand’s behavior in construction and industrial processes.

How Does Ph Affect Sand in Construction?

The pH level of sand affects its chemical reactivity and the stability of construction materials. Acidic or alkaline conditions can impact the performance of bitumen and concrete.

What Role Does Silicate Clay Play in Sand Properties?

Silicate clay affects the cohesion and reactivity of sand. Its presence can influence the sand’s ability to form compounds with other materials, impacting its performance in mixtures and construction applications.

What Is Cation Exchange Capacity (Cec) and Why Is It Important?

CEC measures the ability of sand to hold and exchange positively charged ions. Higher CEC indicates better nutrient and pollutant adsorption, which is crucial for soil health and wastewater treatment.

How Does Sand’s Moisture Content Affect Its Use?

The moisture content of sand affects its workability and bonding properties. Proper moisture levels are essential for maintaining sand’s effectiveness in molding and construction applications.

Can the Properties of Sand Be Improved?

Yes, the properties of sand can be enhanced by combining it with materials like bentonite or by recycling and processing it to improve its grain shape, size distribution, and overall performance.