Introduction of Hydraulic Cement

Water is the biggest enemy of the Civil Engineering Structures. Water can cause great damage to the structures. It is very necessary to protect the structures from moisture which can cause huge damage to the structures.

The other types of cement cannot be used for the construction of the structures which are in contact with water. If we construct the underwater structures with the normal cement then it will undergo corrosion and get damaged.

But you might think that there are many civil engineering structures are constructed like bridges, dams which are in constant contact with water. So how it is possible to built the structures in the water?

There is a special type of cement, known as hydraulic cement, or hydraulic concrete, which is used for the construction of structures that remain in contact with water. In this article, you will get to know all about the Hydraulic cement and the Hydraulic cement applications.

What Is Hydraulic Cement?

Hydraulic cement is a special type of cement which sets quickly and get hardened with the addition of water to the finely ground cement is known as the Hydraulic Cement.

In ancient times, the hydraulic cement was firstly used by the Romans. Hydraulic cement is best suitable for the structures which are constantly in the contact with water.

Hydraulic cement is nowadays widely used in the Construction Industry because it is non-shrinkable, non-corrosive and non-rusting.

Hydraulic cement has the ability to react with water under ambient conditions to form a hardened and water-resistant product. Different blends of modern Portland cement are commercially referred to as the Hydraulic Cement.

Hydraulic cement is a product which generally used to stop water and sets quickly when exposed to the water. Hydraulic cement sets within 5-10 minutes after adding water to it.

It is a type of cement which is similar to the mortar. Hydraulic cement is widely used in the Construction Industry for sealing the structures below grade and in the conditions where structures are submerged in water.

Chemical Composition of Hydraulic Cement

There are mainly four components of the hydraulic Cement

- Belite (2CaO·SiO2)

- Alite (3CaO·SiO2)

- Tricalcium aluminate/ Celite (3CaO·Al2O3)

- Brownmillerite (4CaO·Al2O3Fe2O3)

The mechanical properties of the hydraulic cement are given by the silicates. Some additives are also needed for special properties such as greatly reduced setting and curing time, prevention of shrinking, being able to be used underwater etc.

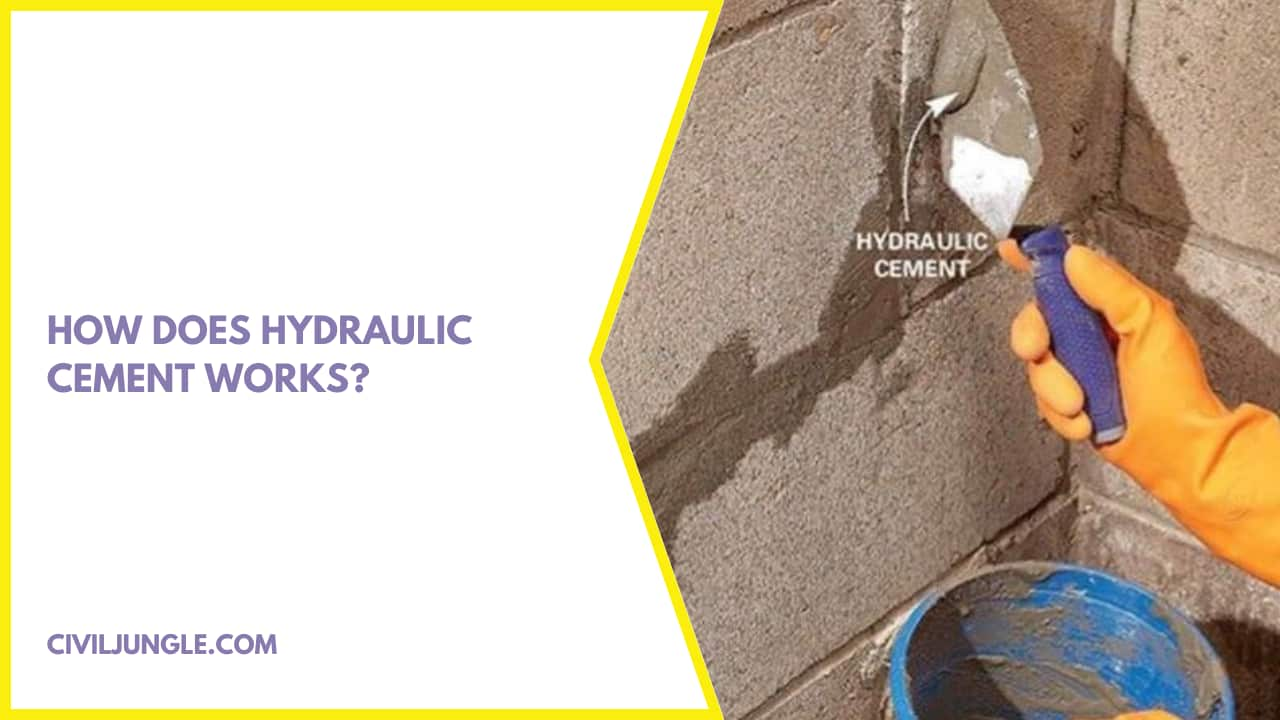

How Does Hydraulic Cement Works?

How to use hydraulic cement involves understanding that it works on the principle of the process of hydration. It means that dry hydraulic cement gets hardened when it is exposed to the water.

The nature of the chemical products which are used in hydraulic cement makes it impervious to the water damages and chemical attacks. That’s why Hydraulic cement is widely used in the construction of the structures which are in contact with water.

The main products in the hydraulic cement are calcium silicate hydrate which increases the strength of the structures and make it watertight.

Suitability of Hydraulic Cement for Construction

- It is important to select the right type of cement as per the nature of the Construction work.

- Hydraulic cement is suitable for the construction projects which required a fast setting and less curing time. Such types of projects give less time to work.

- It is recommended to use hydraulic cement only for the construction works which can be constructed within 10-15 minutes with a moderate amount of cement mix.

- Hydraulic cement has the ability to provide strength for the structures which are in the contact with water. This cement is used for the construction of highly durable structures.

- It is important to taken proper measures while applying the hydraulic cement in the cold climates.

- Hydraulic cement does not shrink like normal cement, and some types even expand while hardening, which is useful for sealing and repair works. This type of hydraulic cement which has the property to expand is very useful for the sealing and repair works.

- Repairing concrete structures with Hydraulic cement is very durable and holds for many years.

Hydraulic Cement Uses

When using hydraulic cement, it is widely employed for the construction of various structures. which are listed are as follows

- Swimming pools

- Foundations

- Elevator pits

- Drainage systems

- Basement walls

- Manholes

- Chimneys

- Cisterns and fountains

- Marine Applications

- For sealing the concrete and masonry structures

Hydraulic Cement Applications in Repairing Work for Civil Engineering Structures.

- Hydraulic cement grouting is also one of the commonly used methods for repairing cracks in concrete.

- Hydraulic cement is used for repairing of dormant cracks in the concrete.

- Hydraulic cement is widely used for the special Repairing work which includes.

- The repairing of the foundation.

- Repair of the cracks in the basement.

- Repairing of concrete walls, floors and driveways.

- Hydraulic cement is also used for sealing and repairing masonry as well as concrete structures.

How to Apply Hydraulic Cement?

- First point clean the surface where the hydraulic cement has to be applied.

- The surface should be free from Oil dirt or any other contaminant otherwise there should not be proper Bond will be formed.

- The area where hydraulic cement to be applied should be saturated for 24 hours before its application.

- To how to mix hydraulic cement, it should be blended with a mechanical mixture to form a uniform mix.

- Add water in it as per the manufacturer’s recommendation.

- If there is excess water remove it otherwise there will be difficulty in its application.

- Apply the hydraulic cement wherever required.

Advantages of Hydraulic Cement

- One of the advantages of hydraulic cement, or hydro cement, is that it is easy to work and apply.

- Hydraulic cement quickly sets and hardened which will help to achieve the desired strength quickly.

- Hydraulic cement is non-shrinkable and does not undergo corrosion.

- Hydraulic Cement is waterproof and can be used for the construction of underwater structures.

- Hydraulic cement is an economical solution compared to other cement products.

- Hydraulic cement is widely used for the construction of durable concrete repair works.

- Hydraulic cement can be used for sealing of the basement and other concrete leakages.

Disadvantages of Hydraulic Cement

- One disadvantage of hydraulic cement, or hydrolic cement, is that it hardens very quickly, making it necessary to use within 10 to 15 minutes of mixing.

- The Hydraulic cement cannot be used for the frozen surfaces.

- Hydraulic cement is not flexible only suitable for providing mechanical support.

- Hydraulic cement cannot be used for the areas where the is below 48°F.

Frequently Asked Questions (FAQ)

What Is Hydraulic Cement?

Hydraulic cement is a type of cement that sets and hardens quickly when mixed with water. It is used in construction projects where structures are in constant contact with water or require fast setting times.

How Does Hydraulic Cement Differ from Regular Cement?

Unlike regular cement, hydraulic cement sets and hardens through a chemical reaction with water, making it suitable for use in wet conditions. Regular cement may not perform well in these environments as it is more prone to corrosion and damage.

What Are the Primary Components of Hydraulic Cement?

Hydraulic cement mainly consists of Belite (2CaO·SiO2), Alite (3CaO·SiO2), Tricalcium aluminate (3CaO·Al2O3), and Brownmillerite (4CaO·Al2O3Fe2O3).

How Quickly Does Hydraulic Cement Set?

Hydraulic cement typically sets within 5-10 minutes after water is added, making it ideal for projects requiring rapid curing.

What Are the Typical Applications of Hydraulic Cement?

Hydraulic cement is used in various applications including swimming pools, foundations, elevator pits, drainage systems, basement walls, manholes, chimneys, cisterns, fountains, and marine constructions. It is also commonly used for sealing and repairing concrete and masonry structures.

How Do You Apply Hydraulic Cement?

To apply hydraulic cement, clean the surface thoroughly, saturate it for 24 hours, mix the cement as per manufacturer instructions, and apply it promptly to the desired area.

What Are the Advantages of Hydraulic Cement?

Advantages include quick setting and hardening, resistance to water damage, non-shrinkage, corrosion resistance, and suitability for underwater construction and repairs.

Are There Any Disadvantages to Using Hydraulic Cement?

Disadvantages include its rapid setting time, which requires prompt application, and its unsuitability for use on frozen surfaces or in temperatures below 48°F. It is also not flexible and primarily provides mechanical support.

Can Hydraulic Cement Be Used in Cold Climates?

Special care is needed when applying hydraulic cement in cold climates. It should not be used in freezing temperatures, and measures should be taken to ensure proper setting and curing.

How Is Hydraulic Cement Used for Repairs?

Hydraulic cement is used for repairing cracks in concrete, sealing leaks in masonry, and fixing issues in foundations, basement walls, and other concrete structures.