Introduction of Helical Piles

Helical piles, often referred to as screw pile foundation detail or helical piling, are a deep foundation system. It consists of a central shaft of various diameters, thicknesses, and spiral plates.

The diameters of helical plates depend upon soil conditions and loading. The helical pile can be used in either residential or industrial foundations.

The foundation is under normal conditions. Helical piles can be used to repair damaged or old foundations.

Helical piles are the most cost-effective foundation system. Helical piles are usually made of galvanized steel. Helical piles are used in caissons, mini piles, etc.

What Is a Helical Pile?

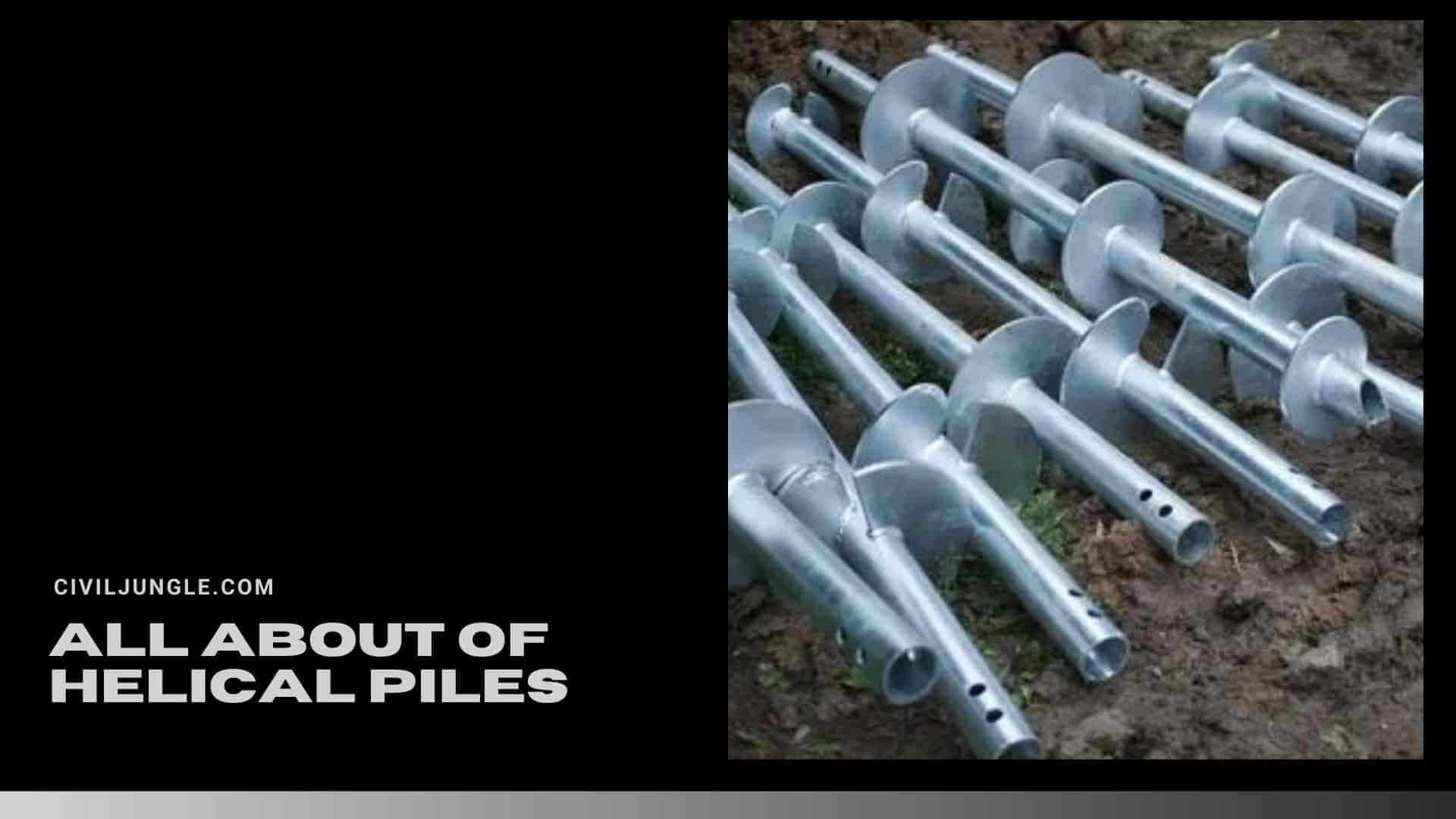

Helical piles are also called helical piers, helical anchors, screw anchors, screw piles, and only helical. Helical piles are constructed using steel shafts.

Various sizes of helical flights are available in the market to suit the site soil conditions. Helical piles are manufactured round hollow bottom and solid square piers.

How Do Helical Piles Work?

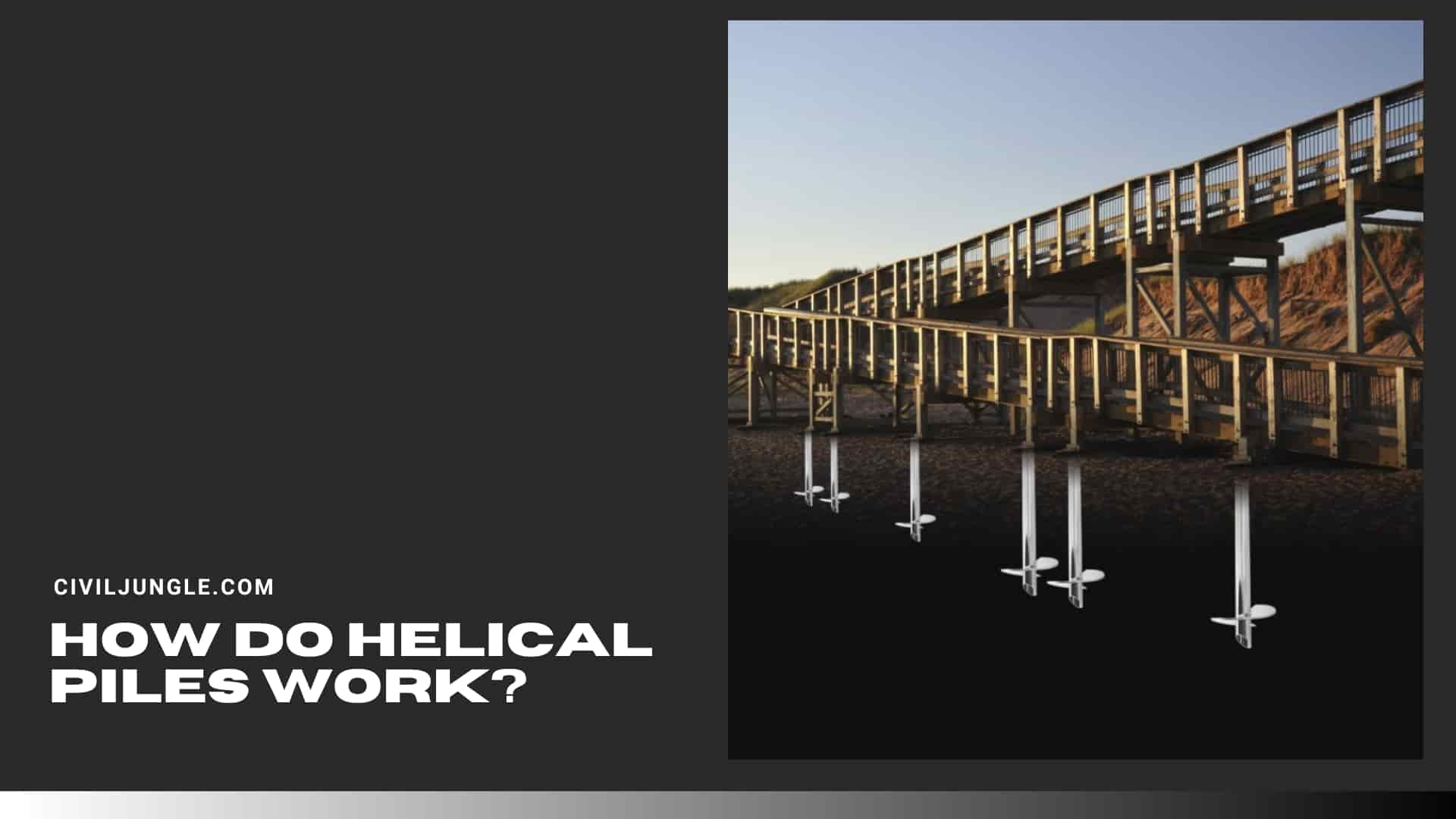

Helical piles, which can be seen as a form of residential helical piles, are installed by rotating them into the soil, just like a corkscrew is twisted into a bottle of wine.

One might wonder, helical pile or concrete: which is better? The answer often depends on the specific requirements and soil conditions.

The shaft of each pile disappears below the face, so fresh extension parts are connected with bolted couplers and screwed into the soil as well evenly performing in a single pile.

In numerous cases, the steel pile itself is enough to meet the cargo conditions of the design. The more robust deep foundation systems, concrete (grout), can be incorporated.

The concrete is continuously poured down the sides of the column, following the relegation plate and boxing the steel shaft.

This fashion produces a collaborated pillar that will repel the most extreme compressive, uplift, and lateral forces.

What Are Helical Piles Made of?

One or more than one helical plate (Steel screw threads) welded onto the shaft to down force to the soil similar to screwed into the earth.

The plane (angle) of the screw is standard, i.e., the size and shape can be suitable on the operation and soil specifications. The head of the pile is fitted with machine-driven, rotary hydraulic attachments.

These are powered by small or large excavators, depending on the size of the pile.For grouted pile is used, a lead relegation plate is fitted onto shaft extensions. The small slice pushes soil out of the way, similar to it is being screwed.

Benefits of Helical Piles

- Easy to install

- Cost-effective

- Minimum impact

- Functional in poor soil

- High loading capacity

1. Easy Installation

- Helical piles are not required specialized machinery for installation.

- The helical pile can be drilled about 10 feet. Therefore it is a fast process.

2. Cost-Effective

- Helical piles are very more affordable to manufacture, transport, and install.

- Helical piles don’t require costly concrete piles.

- A Helical pile can be reused for some form of works of the foundation for other sites.

3. Minimum Impact

- Helical piles should not require more space, human resources, or machinery.

- Therefore they produce a lesser impact on a construction site and the environment.

- Helical piles do not require soil removal; therefore, the wastage of soil is also minimized.

4. Functional in Poor Condition

- Helical piles, especially when considering helical piles in rocky soil, are designed in such a manner that it allows them to contraction the existing soil and apply pressure to it.

- Where soil quality is in poor condition, helical piles are more suitable.

5. Load-Bearing

Helical piles are a wide range of load-bearing capacity.

Types of Helical Pile Design

- Solid square shaft

- Round shaft pipe

- Square and round shaft combo piles

- Grouted square shaft

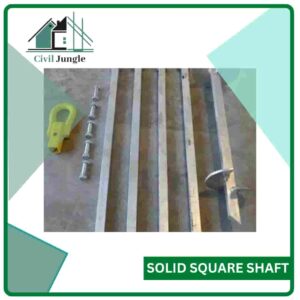

1. Solid Square Shaft

- The square shaft is solid, and it’s able of large axial compressive loads.

- The solid shaft is continuous at each extension. It will be carrying the load down through to the end of the pile.

- Square shaft extensions can also be used in a variety of tension operations.

- The solid square shaft should be various size such as1.5”, 1.75”, 2”, 2.25”.

2. Round Shaft Pipe

- The round shaft pipe helical pile, which can be considered under screw pile foundation details, gives a broader diameter than square shaft piles. This design often influences the overall screw pile cost.

- The wider cross-section provides better structural capacity like as large moments, lateral loading, or buckling.

- The round shaft pipe should be sizes2.875”, 3.5”, 4.5”, 6”, 8”, 10″.

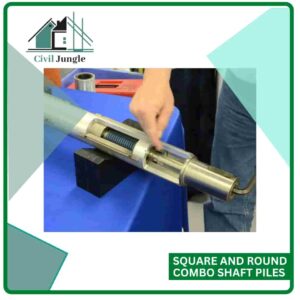

3. Square and Round Combo Shaft Piles

- The combo pile has square shaft piles and round shaft piles.

- These types of helical piles are used in compression applications. The layers of hard soil are located deep under a softer surface soil.

- Square and round combo piles are chosen for high water tables, restricted grout sites. The more economical choice than a grouted pile

- The square and round shaft combo piles should be sizes5”/2.875”, 1.75”/3.5”, 2.25”/4.5″

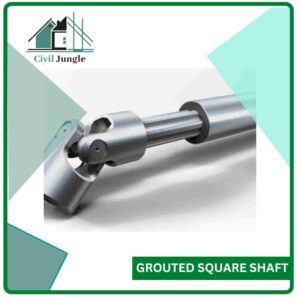

4. Grouted Square Shaft

- All square shaft piles can be fitted with accessories to add a grouted covering.

- This covering is 5” to 8” in diameter and can be cased in PVC or steel pipe, or just grout.

- The grout also creates skin disunion with the soil that can help the contraction and pressure capacity of the pile.

- The larger cross-section should be lateral capacities, bending moment, and buckling resistance strength.

Advantages & Disadvantages of Helical Piles Design

Following are the various advantages and disadvantages of different helical piles design.

1. Solid Square Shaft

Advantages: Solid square shafts are more advanced in rocky and rugged soils without damages.

Disadvantages: Slender shafts don’t repel side lateral loads well and buckle in soft soils due to the narrower range.

2. Round Shaft Pipe

Advantages: Round shaft piles are essential for softer soils when there is an eventuality for grandly side loads.

The round shafts pipe should be grout filled for added structural capacity.

Disadvantages: Round shafts pipe can be more delicate to access very dense or rocky soils.

3. Square and Round Combo Shaft Piles

Advantages: Square and round combo shaft extension to resist buckling and lateral loading.

Disadvantages: In square and round combo shaft piles should be extra material costs. Combo pile solutions are a less economical solution than alternative helical piers.

4. Grouted Square Shaft

Advantages: The square shafts with grout covering are more provident in some conditions than more enormous diameter round shaft pipe piles.

Disadvantages: Grout plates can have difficulty advancing into veritably thick or rocky soils in some cases.

Grout may also be banned from specific systems. Ex. In wetland operations or a point which cannot duly accommodate grout-mixing on point.

Magnum Helical Piles

Magnum helical piles are a more affordable deep foundation.Magnum helical piles are also sensible and more reliable than shallow footing. Magnum helical piles foundations are used for the retaining walls tiebacks.

Magnum helical piles are great for supporting low and high-rise constructions such as residential buildings, commercial buildings, retaining walls, etc. Magnum helical piles foundation supports the loads. The benefits of magnum helical piles foundation are restrictive environmentally sensitive conditions.

Hubbell Helical Piles

Hubbell Power Systems manufactures helical piles. Hubbell Power Systems are supported by technical extension technical services. Hubbell Power Systems is cost-effective and well recognized.

Helical piles are foundation elements that consist of one or more central steel shafts attached to helical bearing plates. Hubbell helical piles provide high capacity and reduce settling and cracking of the residential, industrial and commercial structure.

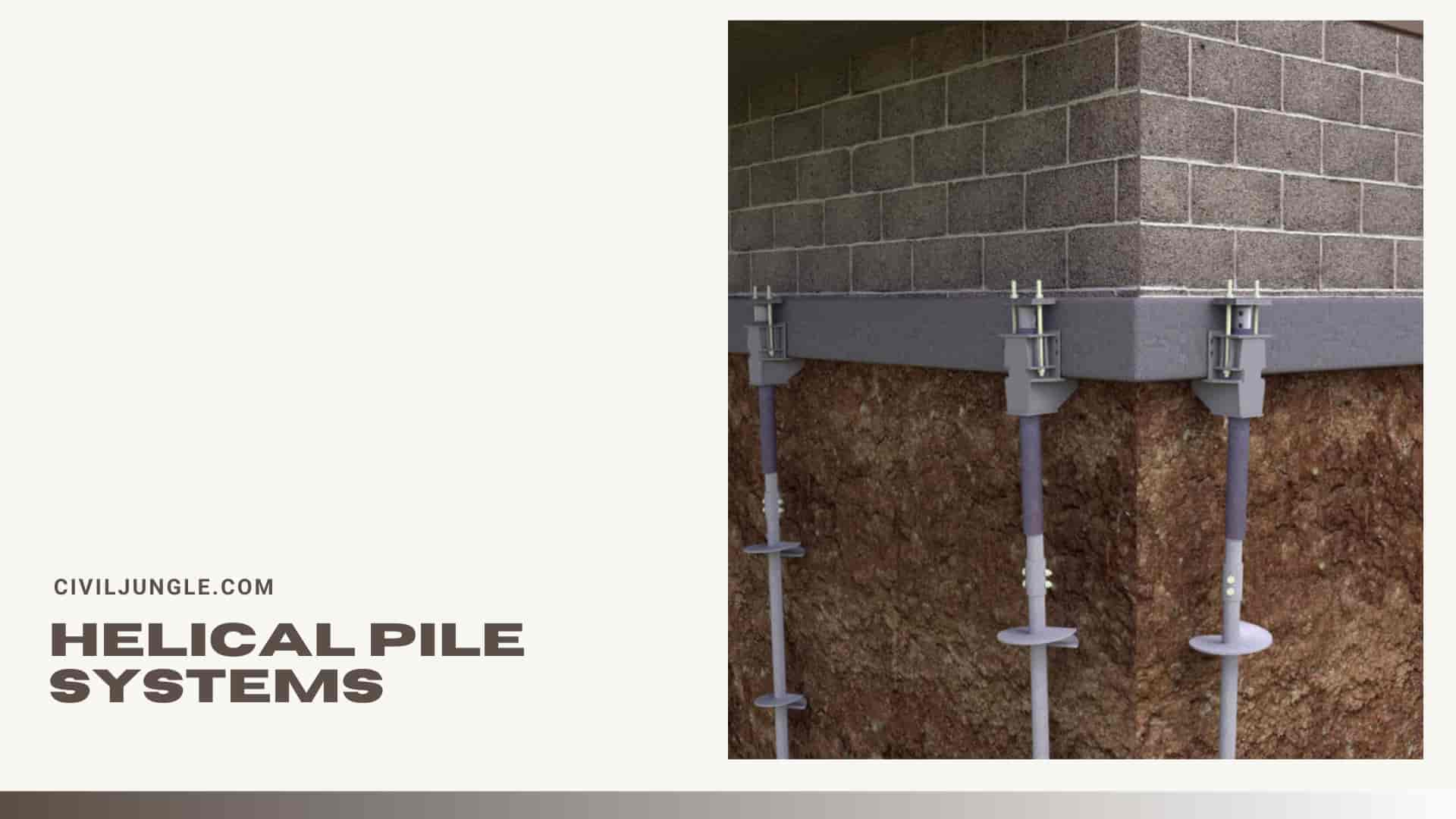

Helical Pile Systems

The helical pile is a deep foundation system with helical bearing plates attached to a central shaft. Through helical bearing plates, the load is transferred from the shaft to the soil. Essentially a result, the helices do not auger into the soil but instead screw into it with minimum disturbance.

The first section is appertained as the lead section, containing the helical plates. The lead section can correspond to one to four helices. Fresh Helix can be added with the use of helical extensions.

Plain extensions are also added until the lead section penetrates the bearing strata, and the necessary torque is achieved. The accurate helix geometry of each steel bearing plate discourages soil disturbance during installation.

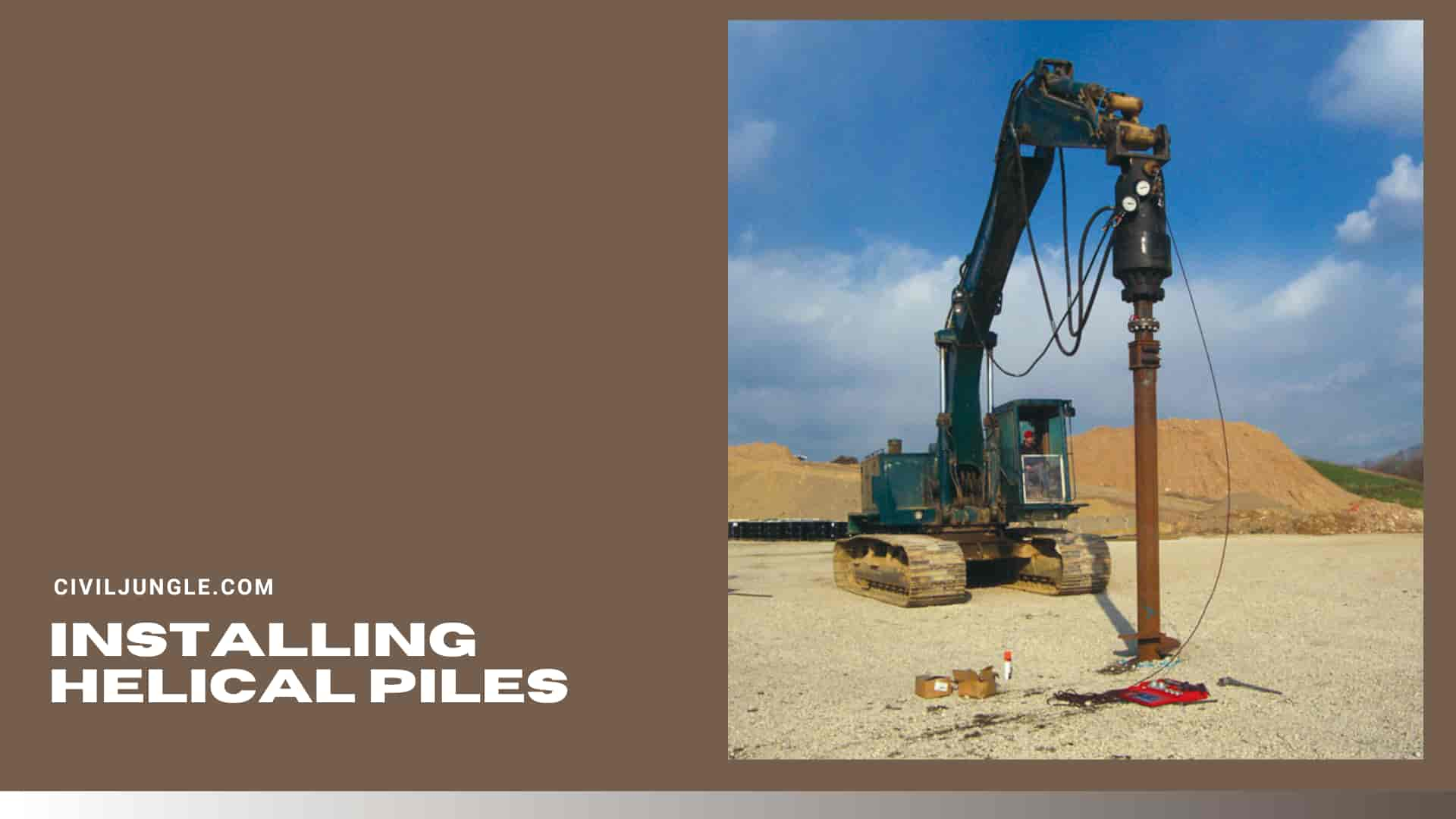

Installing Helical Piles

‘Shaft rotates’ is used for installing helical piles into the ground. Helical piles are installed by rotating the shaft into the pile them into the soil, just like a corkscrew is twisted into a bottle. Helical piles are installed at intervals between the foundation forms and tied into the rebar grid work to pour concrete.

The helical piles are extended to depths attaining the installing torque related to the required load-bearing capacity. Installation can be undertaken by an excavator or hydraulic equipment such as forklifts, cranes, etc.

Helical piles are maintained integrity during installation. Helical piles are commonly used in installation to resist contraction and lateral loading.

Helical Pile Foundation

Helical piles, sometimes referred to as small helical piles, are made up of hollow steel bars. Helical piles foundation will provide stability, safety, and supports, etc. Helical piles foundations are beneficial for many situations such as, the property location has a high water table.

Bad soil conditions on property location, The uneven ground on the building area. When you move location in the future, the structure is temporary. When soil conditions are poor helical piles foundation provides extra support and stability.

Helical piles foundation is an excellent deep foundation option for a building. A Helical pile can be reused for some repair works of the foundation for other sites. Helical piles are easy to use in limited construction sites, high water tables, and weak surface soils.

Steel Helical Piles

A helical pile can be manufactured using a solid square steel shaft and a round shaft open steel pipe pile. Helical piles are also manufactured by the combination of both square and round.

A helical pile can be manufactured using a solid square steel shaft and a round shaft open steel pipe pile. Helical piles are also manufactured by the combination of both square and round.

Helical anchors are steel screw-in piling and ground anchoring systems used for building deep foundations. Helical piles are typically manufactured from high-strength steel. Piles are varying sizes of tubular hollow sections for the pile or anchors shaft.

The pile shaft transfers load of the structure to the pile. In accordance with the intended ground conditions, Helical steel plates are welded to the pile shaft. For the region of manufacture, Screw pile steel shaft sections are subjected to design parameters and building codes standards

The helices are welded over the steel shaft are also called “helical flights” or “flights. These flights can vary in size depending on surface conditions. Helical anchors consist of an extendable steel shaft with helical bearing plates.

Plies should be vital base elements that transfer vertical/horizontal loads. Helical anchors are piles utilized only in pressure like restraining wall tiebacks.

Helical Pile Foundation Cost

Helical pile’s foundation cost depends upon the various variables. It’s consists of soil conditions, the size of structures, the weight, and its design. Following several factors impact the foundation cost of helical piles.

1. Soil Conditions

- Soil conditions are proper when a helical pile is installed.

- Soil is softened, or the natural water table is high, and then invests more cost in it.

2. Types of Helical Piles

- Foundation cost also depends on the types of helical piles.

- There are two main types of helical piles, such as round shafts and one square shaft.

- Depth of installation

- Helical piles must be dug deeper.

- More materials and more time are needed to dig deeper.

- It’s ultimately cost increases in installation.

3. The Number of Helical Piles Required.

- More number of helical piles means more cost.

- The requirements of piles are determined by loading, structure type, and supports.

- The above things are considered in the final estimated cost.

Helical Piers for Pools

Helical piers are the support system of pools. Helical piers are deeply reached into the stable soil to support collections. Therefore helical piers are most crucial for pools. Helical piers are worked for pool easy to installation and technological superiority.

When soil conditions are poor in the construction location, helical piles foundation provides extra support and stability. Concrete pilling should not compete with helical piers. Therefore helical piers are most commonly used in pools.

Ideal Helical Piles

The Ideal helical piles area shelf helical pile foundation system with a locking coupler from the Helix to different pier shaft lengths. This means we can respond fastly with minimum lead time to keep your job going.

1. Done in a Day

- The residential house foundation, Ideal helical piles can be installed in a day, allowing to continue with the construction of the slab straight down.

- This is easily achieved with an off-shelf helical pier system.

2. Measure Process

Every Ideal helical pier is installed to the designed depth and capacity, with readings logged, proof, and reviewed by engineers before subscribing off foundations.

3. Deep Savings

- The concrete piers are changed to helical piers. The deeper foundations have, the greater the savings will achieve over concrete piers.

- Even more significant savings for problem sites,

- Savings start from 1.5m deep.

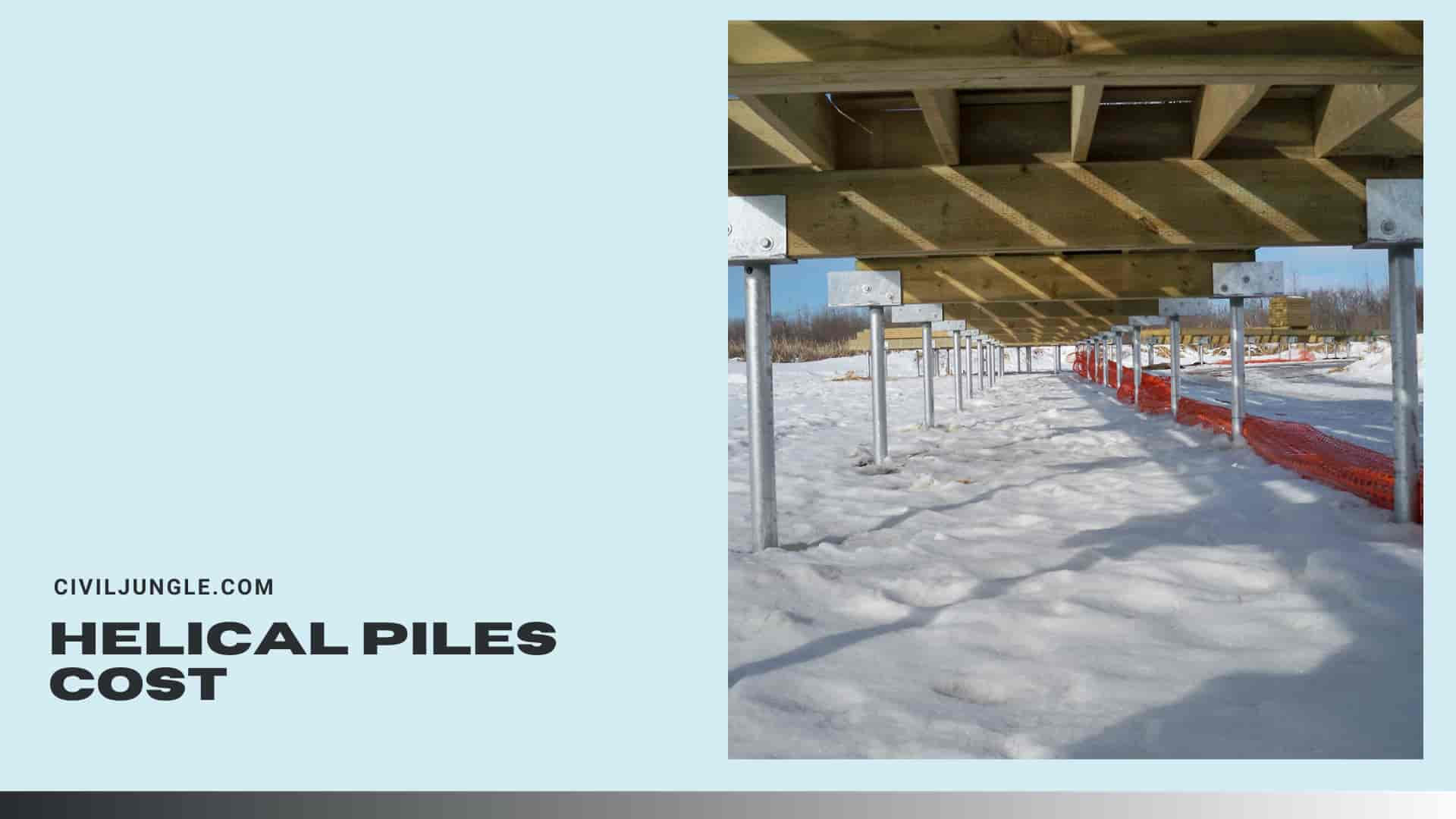

Helical Piles Cost

The cost of helical piles depends upon the adjacent soil conditions, the size of structures, weight, and design.Helical piles are more affordable to transport and manufacture. So, helical piles cost is significantly cheaper.

Helical piles are also less costly to install.A Helical pile can be reused for some repair works of the foundation for other sites. So, helical piles are reusable materials.Helical piles should be fewer mobilization costs associated with driven piles, drilled shafts.

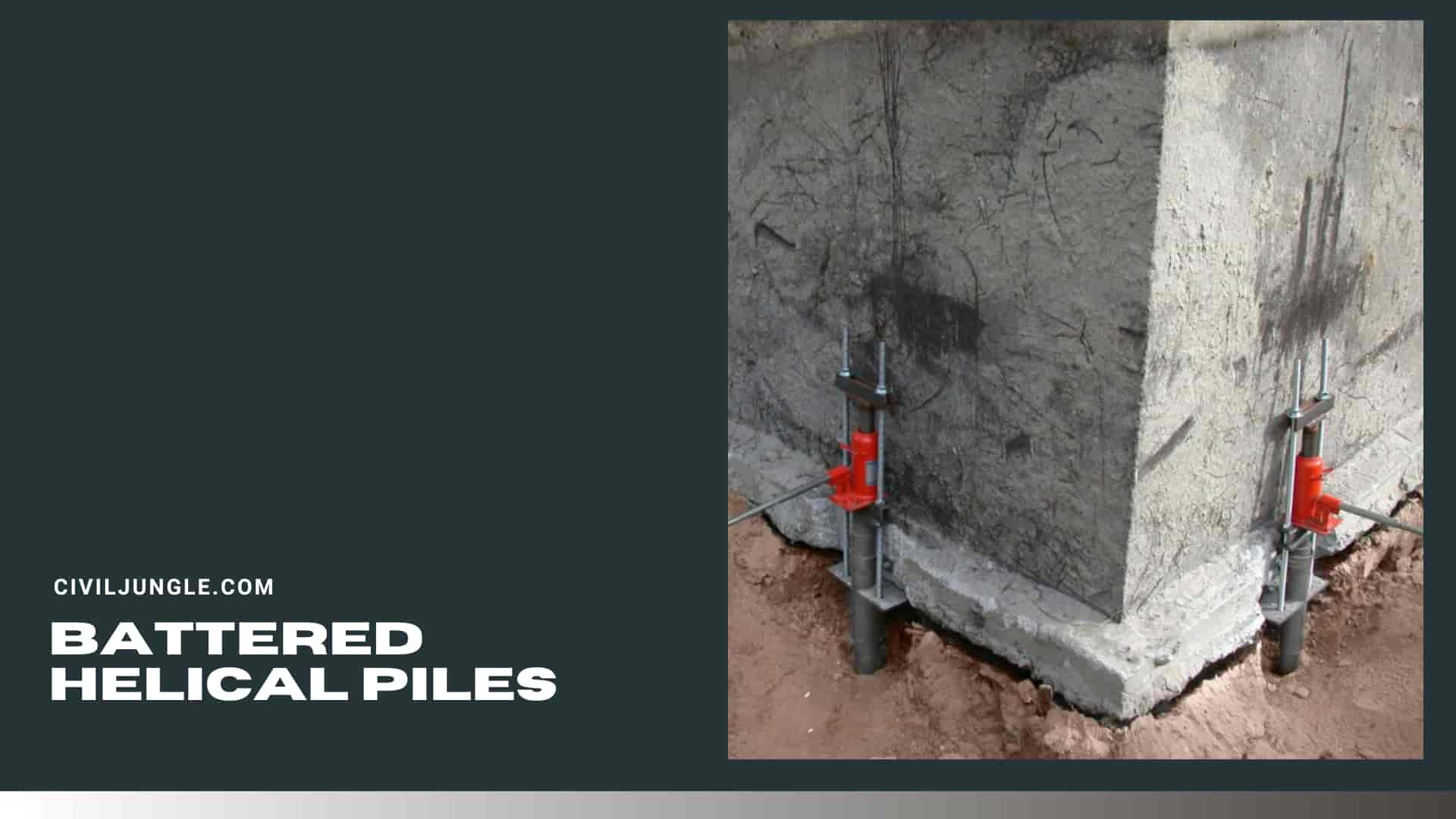

Battered Helical Piles

Battered helical piles can be used for lateral stability. The lower diameter helical piles are generally more practical and cost-effective than large diameter piles. To achieve larger shear and moment capacities, it is also common to batter groups of slender helical piles.

A typical batter angle from perpendicular installation is between 5 and 20 degrees. Via a sword grillage or concrete cap can support shear loads of 10 to 20 kips Each and connect pile group of 3 to 4 slender helical piles joined.

By supporting larger shear and moment cargo , Larger pile groups can be formed. A battered helical pile should transfer a specific amount of the helical pile’s shear cargo and axial pressure and contraction capacity.

This greatly reduces the amount of unresistant pressure applied to the soil and the structural bending capacity needed for that pile. A popular misconception is that the axial capacity of the piles will take all shear cargo. To make this supposition, the pile group must be stationary and rephrasing.

In operation, the pile group isn’t stationary and will transfer cargo both axially and passively along the helical shaft. It is critical to assaya battered helical pile’s structural element and chooses a helical anchor with acceptable structural bending capacity.

Battered helical piles are also efficient in a fixed head situation. The battered helical pile groups are used as a cost-effective piling system for use in light to moderate shear cargo applications when the geotechnical and structural capacities are sized meetly.

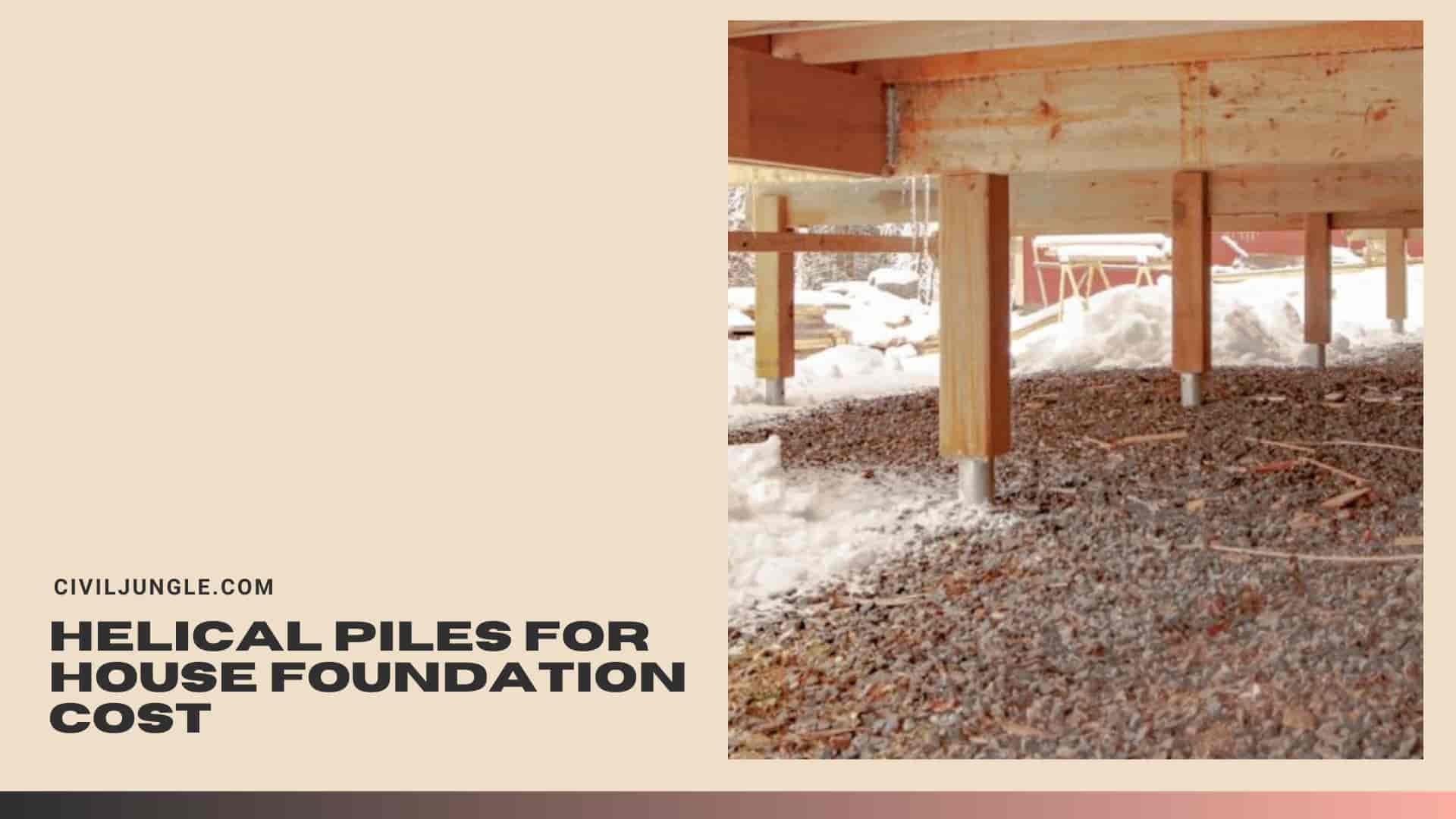

Helical Piles for House Foundation Cost

Helical piles, which can be a choice between helical pile or concrete, should be used for house foundation. Normally, concrete slabs are used for house foundations, but concrete slabs are always the cheapest option. So, helical piles are mostly used for house foundations.

Helical piles are the most cost-effective. For house foundation, a helical pile cost is depends upon the soil conditions, the size of structures, the structure weight, and structure design.

Helical piles, when considering the helical piles price, are very more affordable to manufacture, transport, and install. This is especially true when comparing to the screw pile foundation cost. So, the helical pile system is significantly cheaper.

Helical Piles for Residential Work

Helical piles, including residential helical piles, are used for residential work to stop settlement. Helical piles are also used for residential work to lift the house to show more minor settlements. In a year above ten thousand residential homes built up, helical piles used most of in construction.

Helical piles for residential work are essential to soil conditions. For minimum sized residential homes is require minimum installation. So, helical piles are very useful.

Frequently Asked Questions (FAQ)

What Are Helical Piles?

Helical piles are a type of deep foundation system consisting of a central steel shaft with one or more helical plates or flights. They are used to transfer loads from structures to deeper, more stable soil or rock layers.

How Do Helical Piles Work?

Helical piles are installed by rotating them into the soil, similar to a screw being twisted into wood. The helical plates cut through the soil, allowing the pile to advance to the desired depth where it achieves sufficient load-bearing capacity.

What Materials Are Helical Piles Made Of?

Helical piles are typically made from high-strength galvanized steel. They come in various shapes and sizes, including solid square shafts, round pipe shafts, and combinations of both, with helical plates welded to the shafts.

What Are the Benefits of Using Helical Piles?

Helical piles offer several advantages, including ease of installation, cost-effectiveness, minimal site impact, suitability for poor soil conditions, and high load-bearing capacity. They also require less excavation compared to traditional foundation systems.

What Types of Helical Piles Are Available?

Common types include:

- Solid Square Shaft: Offers high axial compressive loads, suitable for rugged soils.

- Round Shaft Pipe: Provides better structural capacity and is ideal for softer soils.

- Square and Round Combo Shaft: Combines both square and round shafts for versatility in various soil conditions.

- Grouted Square Shaft: Features a grout cover for added strength and stability in specific conditions.

How Are Helical Piles Installed?

Helical piles are installed using rotary hydraulic equipment, which rotates the shaft into the ground. Extensions are added as needed until the pile reaches the required depth and load-bearing capacity.

What Factors Influence the Cost of Helical Piles?

Cost factors include soil conditions, pile type, installation depth, number of piles required, and the complexity of the site. Generally, helical piles are more cost-effective compared to traditional foundation methods.

Can Helical Piles Be Used for Residential Foundations?

Yes, helical piles are commonly used in residential construction, especially in areas with poor soil conditions or high water tables. They can support both new and existing structures, including foundations for homes.

Are Helical Piles Suitable for All Soil Conditions?

Helical piles are versatile and can be used in a wide range of soil conditions, including soft, loose soils, and even rocky terrain. Their design allows them to adapt to different soil challenges effectively.

What Maintenance Do Helical Piles Require?

Helical piles generally require minimal maintenance once installed. Regular inspections may be conducted to ensure the piles are performing as expected, especially in areas with changing soil conditions or high loads.

How Do Helical Piles Compare to Concrete Piles?

Helical piles are often more cost-effective and quicker to install than concrete piles. They also cause less disturbance to the site and can be used in conditions where traditional concrete piles might be less effective.

Can Helical Piles Be Used for Temporary Structures?

Yes, helical piles are suitable for temporary structures as they can be removed and reused for other projects, making them a flexible solution for various construction needs.