Should Concrete Control Joints Be Caulked?

The greatest threat to the satisfactory appearance of concrete and durability of a concrete slab is weather damage since concrete being a porous material absorbs water easily. This absorbed water can result in internal pressure and cracks by getting frozen up.

This circumstance is referred to as the freeze-thaw cycle. Concrete slabs having water under it can also get damaged with due time, as voids are formed in the weak unsupported areas of concrete which due course of time cracks.

So, to prevent all these problems sealing the surface of concrete & filling the concrete control joints with the use of caulk is very much required, in order to retain the new look of your slab.

Cleaning and then sealing of concrete is very important to preserve the beauty of the slab and resist the occurrence of cracks. But caulking control joints is similarly crucial and many times is overlooked.

Caulking the cracks and joints of your concrete is the best way to resist water from entering under the slab. It will help to prevent the entry and set of dust, organic material, and pollutants inside the joints.

It is preferred to use a high-quality, self-leveling caulk that would not shrink and would be quite flexible to remain in place counteracting the bit shift in concrete.

Also, Read: What Is Grade Beam

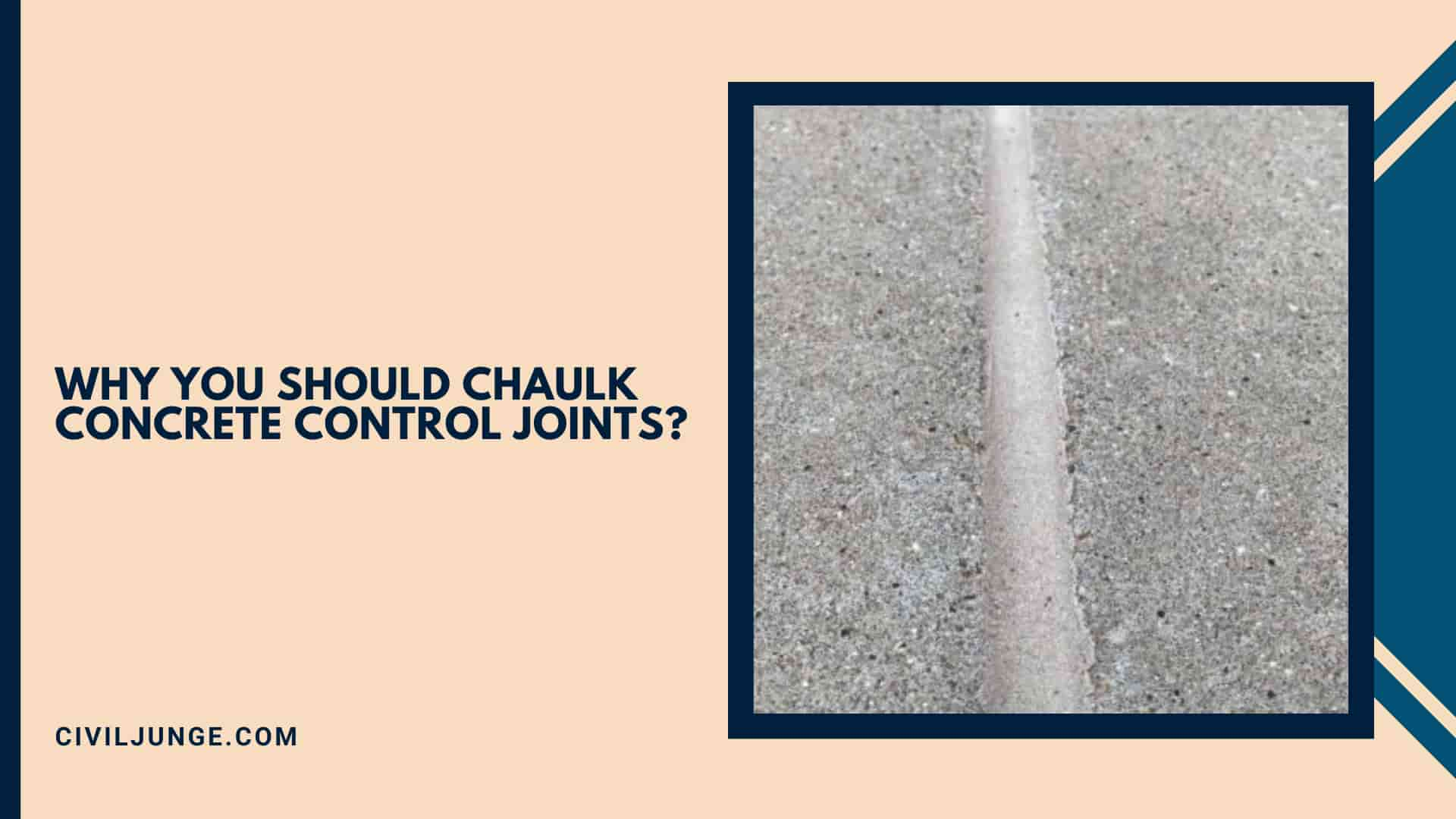

Why You Should Chaulk Concrete Control Joints?

Control joints are the gaps left with an effective reason to counteract the changes in temperature affecting concrete and water absorption by concrete structures.

Concrete undergoes expansion and contraction due to the above-mentioned reasons which can lead to the occurrence of cracks in random areas. The control joints will release the pressure and prevent cracks.

Since the control joints are gaping between concrete sections, they are more vulnerable to a gathering of debris, growth of weeds or collect water. The control joints are the gaps that will advance to the earth, from there growth of weeds, mold, fungus, and bacteria can occur, and water will penetrate into the soil.

If joints are not sealed with caulk can result in various problems, some of which are:

Water Damage

The main reason by far for concrete damage is water. The damage is generated because of the freeze-thaw cycle as well as water invading under-neath the slab. If it is allowed that moisture enters control joints, then it can drain under the slab, which can with the passage of time affect the slab’s stability, resulting in heaves or crack.

Concrete being porous absorbs water, which can freeze. The water that has frozen expands resulting in immense force on concrete. If the force is large the concrete will crack.

Water invading under-neath the slab also affects the soil. It leads to erosion of the soil which is quite dangerous.

Debris

Unsealed control joints will result in the filling of debris in the gap. This can cause various problems. Organic material will cause moss, bacteria, and mold with the passage of time.

Caulking of the control joints will help prevent the entry of debris growth of dirt and other organic materials.

Weeds

Weeds & Grasses are another big problems caused by unsealed control joints. A good thick base lay will also not prevent them from occurring.

Weeds consist of strong roots, which can work their way through hairline cracks, and make them open much wider and make them worse. Caulking would be a great way to prevent them from growing..

Also, Read: What Is Pier and Beam Foundation

Joint Caulking Vs Filling

Joint caulking and caulking have a huge difference in them. Caulking with the use of high-quality concrete caulk is recommended rather than filling the gaps.

Joint Sealing

It is executed using self-leveling caulk. This type of caulk should be preferred use to seal control joints against moisture and other destructive materials. It is preferred for exterior concrete joints, but at the same time can also be used for interior concrete joints.

The caulk used is most of the time a soft and flexible one. This type of work can generally be used temporarily and can be re-applied and removed as and when required.

Joint Filling

Material to be used for joint filling is generally hard in nature, non-flexible, stiff, and for permanent use. They are applied for interior use.

So, the main and considerable difference between control joint fillers and sealants is their flexibility. An example of joint filler used is mortar or grout.

They perform better in controlled environments like interior spaces, where there is no problem of getting wet and temperature change-related problems.

Caulk is best suited for exterior purposes, as being flexible can counteract environmental changes, and perform well in numerous conditions.

Alos. Read: Types of Drilled Piers

How to Caulk Concrete Control Joints?

The initial step in caulking control joints is to make sure they are clean. A pressure washer is applied to get rid of any kind of dirt or debris. A low-pressure setting is to be used.

The right type of caulk is to be chosen for the job. One that is self-leveling and flexible is to be bought. Though it will cost a bit high the work will be quite effective. Non-self-leveling caulk can be quite messy.

The list of materials & tools that will be required is as follows:

- Caulk.

- Cleaning Supplies.

- A Caulk Gun.

- Hose or Pressure Washer.

Silicone or polyurethane-based caulk is recommended to be used to seal the concrete control joints. Both of them are quite durable and flexible in nature.

Silicon will last for a longer time than polyurethane since silicon has a better capacity to prevent degradation. While silicon is harder to work with.

A good quality caulk gun having a pressure release button is to be used. In the absence of the release, caulk will continue to shoot out the tip of the gun after the handle has been released. This would lead to mess around the concrete and the worker.

Caulking Expansion Joints

Caulking is the number one defence against water and air infiltration. By stopping air and water from entering into the expansion joints, caulking can help to prevent mould growth, material deterioration, and moisture issues within the expansion joint systems.

Caulking Driveway Expansion Joints

Expansion joints must be sealed with a flexible sealant, like QUIKRETE® Self-Leveling Polyurethane Sealant or QUIKRETE® Non-Sag Polyurethane Sealant…or an expansion joint strip, to prevent water from penetrating the joint and deteriorating the sub-base.

Best Sealant for Concrete Cracks

That means Loctite PL Concrete Non-Sag Polyurethane Sealant is the right choice: it’s a concrete caulk that is suitable for repairing cracks in vertical and horizontal surfaces and bonds to concrete, brick, stucco, metal, wood, vinyl, fiberglass, and other substrates.

Should Concrete Control Joints Be Caulked?

Caulked concrete control joints are very important if you want to preserve your slab and keep it looking like new. Cleaning and sealing your concrete is important to preserve the slab’s beauty and prevent cracks. But caulking control joints is just as crucial and often overlooked.

Best Caulk for Driveway Joints

The best option for sealing expansion joints is a flexible silicone sealant like Concrete Elite from Silicone Depot. Concrete Elite lasts up to 10x longer than common polyurethane sealants.

Expansion Joints in Concrete

A concrete expansion joint – or control joint – is a gap which allows the concrete to expand and contract as/when the temperature changes. It forms a break between the concrete and other parts of a structure to allow movement without causing stress, which can lead to cracking.

Joint Sealant

Joint sealants are used to seal joints and openings (gaps) between two or more substrates and are a critical component for building design and construction.

Best Wood Filler for Trim Joints

- 1 Minwax Stainable Wood Filler.

- 2 Elmer’s Carpenter’s Wood Filler.

- 3 Goodfilla Wood & Grain Filler.

- 4 DAP All Purpose Wood Filler.

- 5 Elmer’s E892 – Stainable Wood Filler.

Like this post? Share it with your friends!

Suggested Read –

- Anatomy of Stairs

- Acid Vs Water-Based Concrete Stain | What Is a Stain | Concrete Stain Vs Paint

- What Is Gypsum Plaster | 15 Advantage of Gypsum Plaster | Disadvantage of Gypsum Plaster

- What Is M Sand | Properties of Manufactured Sand | Advantages & Disadvantages of Manufactured Sand

- What Is Dampness | Requirements of an Ideal Material for Damp-Proofing | Materials Used for Damp-Proofing