What If Concrete Is Too Wet?

In a specific ratio cement, sand, and stones are mixed for making dry concrete. After the mixing of water, it reacts with cement and forms a chemical reaction then forms a paste, which helps in binding the ingredients together.

With the passage of time the water starts evaporating out with the drying of concrete after it gains strength over a long period of time. This process is known as attaining the compressive strength of concrete. It takes nearly around 28 days for attaining complete strength.

One of the biggest that can be done by you is adding excess water than required. The concrete being too wet can reduce the final strength of concrete.

A disaster can occur for intense structural projects such as footings and foundations that will require strong concrete. This is the reason why careful monitoring is to be done to the amount of water that is to be added and then mixed.

During the drying process if concrete gets more wet than required then it will lead to excess shrinkage. Due to which, the concrete gets prone to cracks which can be quite dangerous in due course of time for total rupture of structure.

The main problem is the weakness of concrete of excess watered concrete. It is a greater problem than cracks. The required compressive strength sometimes massively decreases due to the excess water.

There is a thumb rule present, with each inch of slump reduction of compressive strength of concrete occurring nearly around 500 psi. For heavy weight carrying need their occurs disasters. The ideal consistency can be known to be reached when it is not over ready if normal consistency is required.

Understanding Concrete

One of the most broadly used construction material all-over world is concrete. This is a man-made material that is made by the mixture of cement, sand, and stone along with water.

Depending upon the grade of the concrete the quantity of different ingredients changes. Usually 10% of cement, 20% will be water, 30% of sand and 40% will be gravel. Each ingredient is very much essential for making proper concrete.

The consistency of mix and the type of ingredients used specify what will the concrete’s quality. Quikrete is a company that sells dry mixes. All the quality control and measuring are done by the company by us. The important thing you need to do is adding of water.

If wet concrete is brought then all process of mixing water is also done by them. If own concrete is made by you on the site then measurement of ingredients is to be done by you.

The calculations and addition of water is also to be done by you. You should inspect the quality of ingredients to be added, the size and shape of aggregates.

When mixing your concrete or Quikrete, the water level is to be made accurate and calculations should be done in that way.

If the mix done at last has soup-like consistency, then dry mix is to be added for balancing things out. If the concrete brought by you from a plant is too wet required it is to be returned immediately. In that case losing a bit of time is much advantageous than putting too wet concrete to use.

In big projects there will surely be someone for inspecting the mix before it is to be poured. You should be cautious of the fact that masons and concrete companies will be adding extra water for making concrete to make the work easy for them. If you get to notice those things try to tell them to add extra dry mix for maintaining the consistency.

Also Read: Concrete Slab Construction Methods

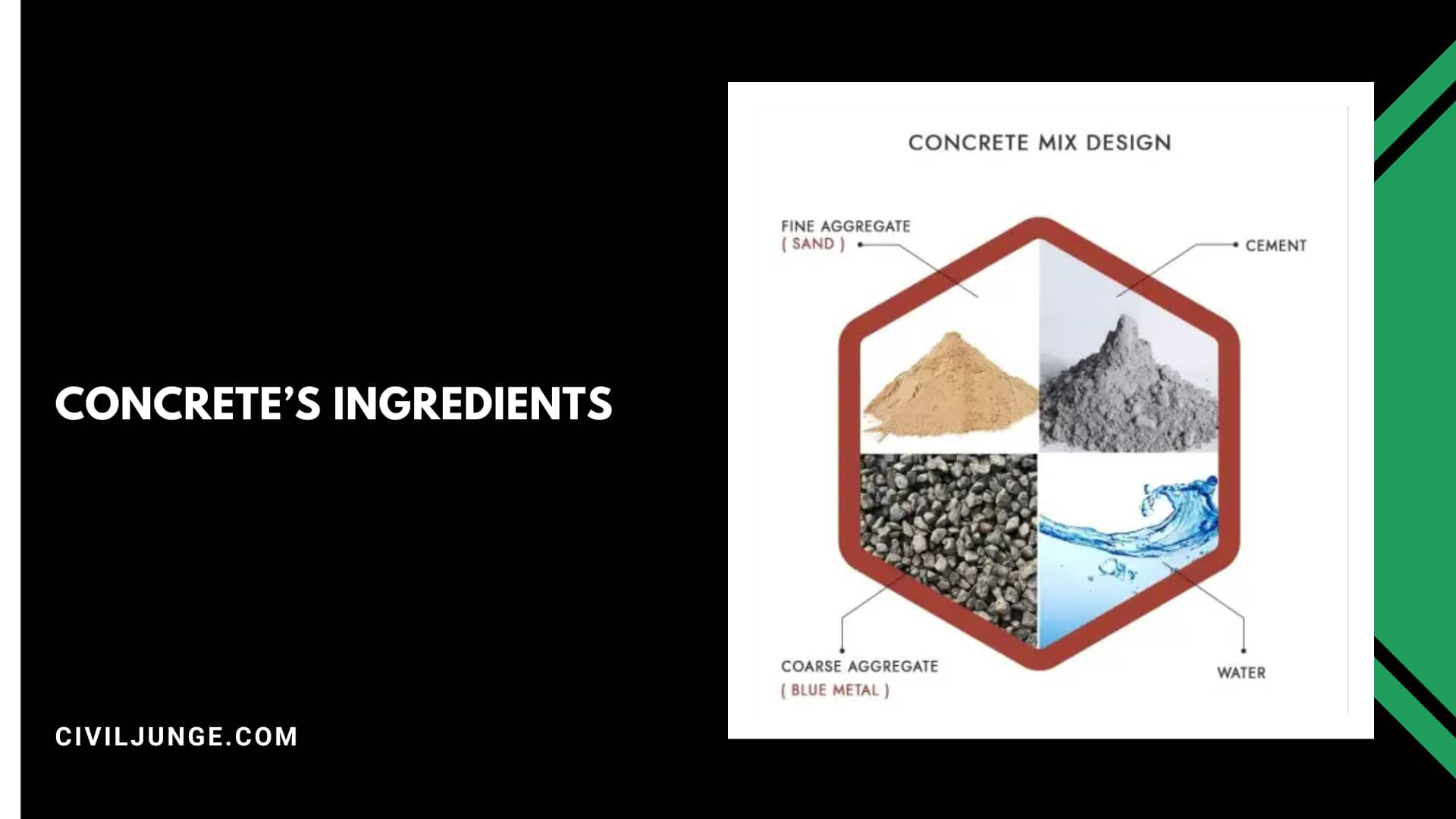

Concrete’s Ingredients

The ingredients of concrete are to be known properly to understand what is the reason for the problem of wet concrete. Concrete at start is a dry powder and man-made material.

Water when added to the powder starts chemically reacting and helps in forming a paste. Cement one of the ingredients, mixes and forms a bind with other ingredients finally after drying forms a strong concrete.

Curing is also very essential if you want your concrete to attain proper strength. Water is an extremely important ingredient, since without it a paste could not be formed. The concrete without water will remain dry and not result into a paste.

So, what is required is just right amount of water to help forming a standard consistent mix of concrete, not more than that neither less. If any ingredient remains dry then extra water can be added.

While if the concrete forms a soup like consistency, then it is not proper, the consistency should be like oatmeal a snowball can be formed with the concrete mix. The seeping of concrete through your hand signifies wet concrete. Extra water will lead to breaking, cracking, additional pores, and overall weakness.

Also Read: What Is Stronger Than Concrete

Cement

Cement is one of the active ingredients of concrete which helps in formation of bind and glues other ingredients together. Even though its portion is small but this is very essential. Without it concrete will remain a dry pile of stone and sand.

Water

Water is the ingredient that helps in the activation of cement. Without concrete will be powdered material. While its quantity should be properly maintained, because excess water is not recommended neither less water is proper. Excess water will make concrete weak and less water makes it brittle.

Concrete being too wet, the excess water will evaporate that will lead the concrete to shrink and form crack. This forms the concrete weak and extremely porous.

So, it is very important to get right water level whenever concrete is being mixed. It is to be made sure that clean water is being used. Salts and contaminants will damage the concrete.

Aggregate

The aggregate materials consist of sand and gravel.

- More grit is provided by sand. Binding is increased due to this ingredient.

- Stone gives strength to concrete, more usage of concrete PSI of concrete increases. Rounded aggregates give more strength.

Better interlocking property is given by angular aggregates.

- 1/2inch-1inch diameter aggregates are recommended to be used.

- Sand and gravels help in limiting shrinkage when concrete is being cured.

- With the variation of sand and gravel their occurs alteration of properties of your concrete.

Also Read: All About Concrete Bond | Will Concrete Bond to Concrete | How Concrete Adhesion Works

When Concrete Gets Too Wet?

Concrete being too wet, concrete gets over porous and will lead to cracks. The excess water present will evaporate and result in escaping from the hardened concrete surface which leads to cracks and eventual breakage.

The concrete can be tested if there is confusion by carrying out slump test or by grabbing a small portion of concrete if a ball formation can be done without concrete getting slipped then it is ok.

The strength of dried concrete reduces if your concrete is too wet. The compressive strength of concrete reduces up to 500 psi with the addition of extra inch in the slump. It is very much problem creating conditions for heavy load-bearing structures.

An essential concrete mix is required, it is not acceptable to get one batch different from the other batch. The dry ingredients and water should be properly measured and then mixed.

If by any mistake the water gets more than that required you should not throw the mix, it is recommended to add more dry mix unless you attain the required consistency.

But that is not always acceptable more often you need to start all over again by rejecting the initial mix. Concrete being porous absorbs water like sponge. Holding of excess water for a long time will lead to the formation of cracks and reduction in strength.

Concrete being too wet results them to be getting bigger pores. A good quality scaler is recommended for keeping the water out.

Concrete Bleeding

Bleeding is sometimes referred as water gain. It is a particular form of segregation, in this case water comes out to the surface of concrete.

Highly wet concrete mix, badly proportioned and insufficiently mixed concrete generally undergoes bleeding. Bleeding results in the accumulation of water at the surface of concrete. Working up of the surface of concrete with floats and trowel, results in lowering of aggregate and cement and water to come up to the top surface.

“Laitance” is the word given to the cement paste formation at the surface. Owing to the fact the top surface will be having higher content of water and they get removed of aggregates, so therefore shrinkage cracks form.

If water cement ratio provided in your concrete is more than 0.7, the bleeding channels will be continuous in nature and remain unsegmented due to the development of gel. This bleeding channels will be responsible for the cause of permeability of concrete structure.

While the mixing water leads to come up, it may be blocked up by aggregates. The bleeding water leads to get accumulated below aggregates. This water accumulation leads to the formation of water voids and results in bond reduction between aggregates and pastes.

Bleeding rate increases with the passage of time up to near about one hour, then the rate starts to decrease but it not stops. It continues to occur until the final setting time of concrete occurs.

The bleeding is not totally harmful if the evaporation rate from the surface goes at par with the bleeding rate. After the role of water is done in workability, its removal from the concrete with the help of bleeding is perfect for the concrete.

After the concrete loses its plasticity, it is the delayed bleeding that causes harm to your concrete. The usage of proper material proportioning along with uniform mixing, usage of finely divided pozzolanic materials along with air entraining materials will help in reduction of the harmful bleeding.

Estimating the Water to Cement Ratio for Concrete

The strength of concrete is primarily dependent on cement paste strength. The paste strength increases with the increase in cement content while reducing with air and water content.

The lowering of water cement ratio can be used when the concrete is vibrated for achieving higher strength. Water cement ratio for getting the water required for chemical combination with cement and for occupation of gel pores if theoretically seen is about 0.38.

Usage of water cement ratio more than that will lead to capillary cavities whereas lower than that will lead to incomplete hydration and space reduction for the gel development.

The higher water cement ratio can be used by us when you hand compact your concrete. If a graph is formed the relation between strength and water cement ratio will be hyperbolic in nature.

So, for getting the proper water cement ratio mixed design of concrete is to be done. Mixed design can be done in various methods such as American Concrete Institute Method of Mix Design, DOE Method of Concrete Mix Design, Indian Standard Concrete Mix Proportioning. Generally in India IS 10262:2009 is followed for getting the proper water cement ratio for your concrete.

How to Fix Concrete with Too Much Water?

If the batch is freshly mixed, you can simply add a small amount of dry concrete mix to even out the ratio. Stir the combined mixture around until it has reached the right consistency. Only use a little bit at a time or you might go from a mixture that is too wet to one that is too dry.

Too Wet Concrete May Cause

When a concrete mixture is too wet, it causes a greater amount of shrinkage during the drying process than is needed. As a result, the concrete has a great likelihood of cracking and for those cracks are likely to be a fairly good size.

Will Concrete Dry If Too Wet?

When concrete is too wet it dries weaker, overly porous and prone to cracking. Excess water will evaporate and escape the hardened concrete which causes cracks and eventual breakage. You can if your concrete is too wet using the slump test.

How Wet Should Concrete Be?

The concrete should have a peanut butter-like consistency. It should not be soupy. If so, add a small amount of dry concrete to stiffen the mix.

Too Much Water in Quikrete

NOTE: the more water that is added to the mix the weaker it becomes; adding one extra quart of water per 80 lb bag can reduce the strength of the concrete by up to 40%.

What Happens If Concrete Is Too Dry?

If it dries too quickly, the surface of the concrete will be weak, and will be subject to spalling. Spalling happens when a weak surface layer of concrete allows water to infiltrate. The water freezes and breaks up the surface of the concrete.

How to Tell If Concrete Is Too Wet?

When concrete gets too wet, it becomes weak and prone to cracks, breakage, weakness and failure. The ideal consistency should feel like thick oatmeal and should never be watery. When concrete has too much water it also dries more porous. This is because of all the water that needs to evaporate out.

What Is 3500 Psi Concrete Used for?

3,500 PSI ready mix concrete can withstand slightly higher levels of compressive force which is why it can be used for driveways/ parking areas for heavy vehicles, as well as structural components like foundation footings and slabs. It is often used for beams and girders found in bridges.

Is Cement Porous?

According to research conducted by CSHub, the French National Center for Scientific Research, and Aix-Marseille University, cement paste is so porous that 96 percent of its pores are connected. Despite this porosity, cement possesses excellent strength and binding properties.

Difference Between Cement and Concrete Driveway?

Bottom line: Cement is a powdered ingredient used to make concrete. Concrete is the material used to make sidewalks, driveways and buildings.

How Is Concrete Made?

To make concrete a mixture of portland cement (10-15%) and water (15-20%) make a paste. This paste is then mixed with aggregates (65-75%) such as sand and gravel, or crushed stone. As the cement and water mix, they harden and bind the aggregates into an impenetrable rock-like mass.

Cement Ingredients

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

What Are the 4 Main Ingredients of Concrete?

Concrete is a mixture of cement, air, water, sand, and gravel–it’s as simple as that! Not exactly. The typical concrete mix is made up of roughly 10% cement, 20% air and water, 30% sand, and 40% gravel.

What Is Cbr Test in Civil?

CBR Testing (California Bearing Ratio) is primarily undertaken to provide data for road pavement design. It was first developed by the California State Highway Department. It is a penetration test which is used to evaluate the subgrade strength primarily of roads, pavements and foundations.

Concrete Bleeding

Bleeding in fresh concrete refers to the process where free water in the mix is pushed upward to the surface due to the settlement of heavier solid particles such as cement and water.

Types of Bleeding in Concrete

The Normal Bleeding refers to the process of uniform seepage of water over the entire surface of the structure. The channel bleeding is a process by which water rises through certain specific paths called as the channels. Not all the bleed water will reach the concrete surface.

Effect of Bleeding in Concrete

Bleeding water causes high water-cement ratio at the top of the surface. It loses the homogeneity of concrete. It decreases strength and wear resistance of concrete. It makes the poor bond between two layers of concrete as well as the bond between concrete and reinforcement.

What Causes Bleeding in Concrete?

Bleed in concrete is the result of excess water being forced to the surface of the concrete. Understanding the cause of bleed can assist in properly managing and eliminating its occurrence. The four primary ingredients of concrete are stone, sand, cement and water.

How to Reduce Bleeding in Concrete?

- Maintain a strict water to cement ratio.

- Add sand.

- Add Supplementary Cementous Materials (SCM’s) into your mix.

- Add air entrainment to the mix.

1:2:4 Water Cement Ratio

1:2:4 represents the amount of cement, fine aggregate (sand) and coarse aggregate to be added during batching of concrete. If we need to calculate Water quantity for concrete, first find the cement content for the volume. Therefore, Required amount of water = 0.5 X 50 kg = 25 litres / 50 kg cement bag.

Water Cement Ratio for Concrete Strength

The practical range of the w/c ratio is from about 0.3 to over 0.8. A ratio of 0.3 is very stiff (unless superplasticizers are used). A ratio of 0.8 makes a wet and weak concrete.

Water Cement Ratio Formula

How To Calculate Water Cement Ratio ? For example if the water-cement ratio is 0.50 for concrete and cement added is 50 kg (weight of 1 bag of cement). Water = 0.50 x 50 = 25 liters. As you see, the water is reduced as we decrease the water-cement ratio.

Maximum Water-Cement Ratio

So most of the standards recommend 0.70 as the maximum value for w/c ratio. Higher is the aggressiveness of the environment lower should be the w/c ratio. For concrete exposed to a very aggressive environment, the w/c should be lower than 0.40.

Water Cement Ratio in Concrete

What is water cement ratio ? It is the ratio of the mass of water to the mass of cement added to concrete. The water cement ratio formula directly affects the strength & durability of the concrete. The typical water-cement ratio varies between 0.40 – 0.60 for different grades of concrete mix.

Like this post? Share it with your friends!

Suggested Read –

- What Is Kerbs

- Pile Cap Concrete

- Stretcher Course Brick

- Concrete Cantilever

- Beam Load Calculator

- What Are Superplasticizers

- Epoxy Flooring Cost Calculator

- Initial Setting Time of Ppc Cement

- All Cement Price List May 2023 | Cement Price Per Bag | May 2023 Cement Price

- What Is Seasoning of Timber | Type of Seasoning of Timber | Benefit Seasoning of Timber

- What Is Quarrying of Stones | Methods of Quarrying | Selection of a Site for Quarrying of Stones