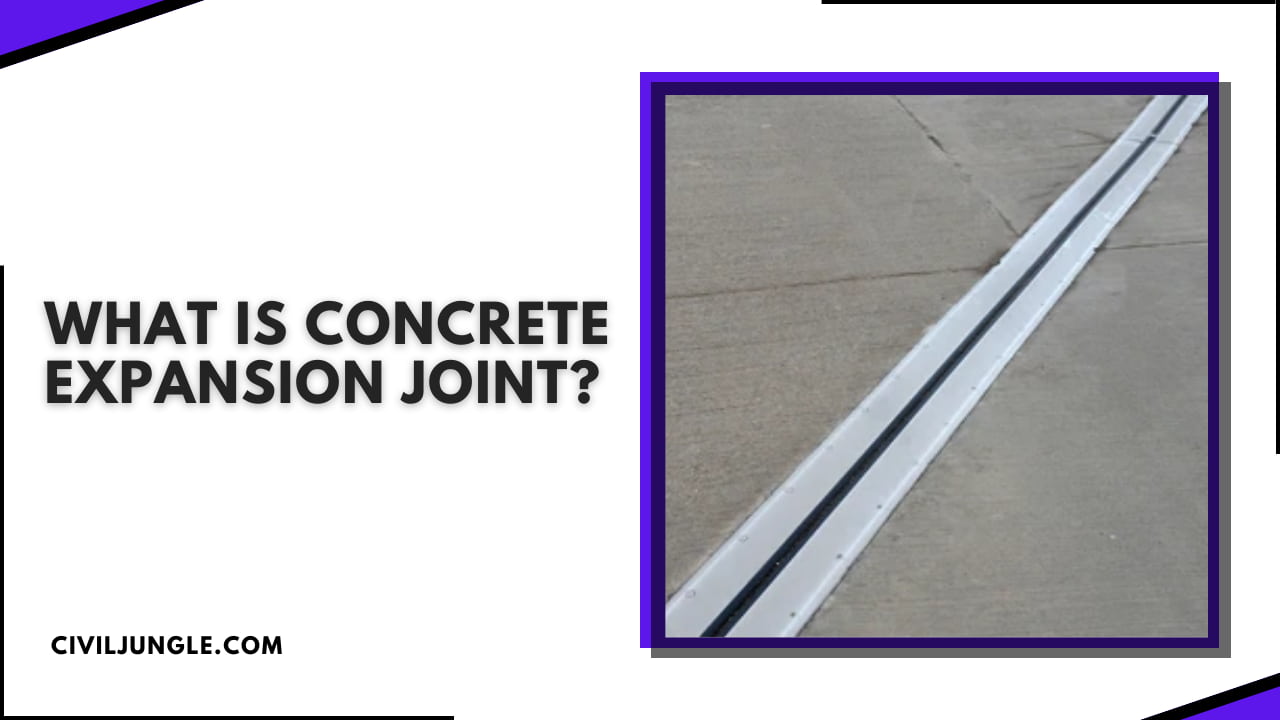

What Is a Concrete Expansion Joint?

Concrete expansion joints are primarily a place or gap between two parts of a substantial plate; this space permits every definite dish to shift single-handedly and quickly from everyone.

You may imagine concrete is so tricky that it does not redirect, but that’s not the fact concrete regularly increase and design as it shifts climate.

It can also move a limited with the motion of the ground concrete expansion joints, giving the plate fair and sufficient free space to change, which supports to stop break and collapse beyond these joints. Also, a slight change discovers stress and strength on the concrete.

Later powerless dots can fracture or collapse. Expansion joints will operate to comfort this strain, and expansion joints will stuff with an elastic element that is active across and interior of the joint or space in plates and extra concrete construction.

An expansion joint will install to soak the development and structure of concrete because of the switch in condition. Awareness of the want for expansion joints is required to design them properly.

Demanding and helping break in a plate is main also significant the kind of expansion joint to apply in your particular circumstances.

- How to Reduce Construction Cost (Tips)

- How to Building Construction Process Step by Step

- All About Tendering | What Is Tendering | What Is a Tender in Construction | Tendering Meaning in Construction

- Top-Down Construction | What Is a Top-Down Construction | Advantages & Disadvantages of Top-Down Construction

- House Construction Cost Calculator | How to Work With House Construction Cost Calculator. | What Is Construction Rate

- 20 Vastu Tips Before House Construction | Vastu Tips for Different Locations of House | Scientific Facts of Vastu Location of Rooms

Why Do You Need Concrete Expansion Joints?

Holding an expansion joint in a concrete plate avoids snap and going. Joints block harm to the dish, which constructs them continually and makes them appear finer. By counting expansion joints, there is a point for the materials to incase disturbed.

If a concrete plate is considerable and does not have expansion joints, in case the formation crook, impulses, amplify, or arrangement, the strain and burden discover comfort by chasing. Expansion joints are applied to deflect these snaps.

Joints are involved in the location where two plates of concrete catch, when a slab chance else formation adore a wall or although a substantial space is lengthy. A 100 ft. concrete path will not flood in one long slab.

You have obtained gobs of cleave. Sooner we slice expansion joints which fragment the course into the junior bit. These little solid plates can displace more direct support to beat breaks and submission.

Characteristics of Concrete Expansion Joint

The necessary cause of an expansion joint is to support the expansion around the plaster. Expansion joints give the concrete e virtually to go as it shifts. Missing a space for the concrete to develop into, strength constructs of, and probably slice a powerless lot in the slab.

Concrete shift varies in a climate far beat and motion on the planet. Joints even carry concrete solid when the mud through it will determine.

The expansion joints are more attractive in any place concrete will obtain on the surface. The path, route, courtyard, and street all give expansion joints to blockage fracture.

- Best Concrete Mix for Driveway Repair

- Why Is Polymer Mortar/Concrete | Types of Polymer Mortar/Concrete

- What Is Micro Concrete | How to Apply Micro Concrete | What Are the Benefits of Micro Concrete | How Is Micro Concrete Used

- Concrete Batching | Concrete Batching Plant | Types of Batching of Concrete | Various Factors Affecting the Choice of Batching System

Types of Concrete Expansion Joints

There is a lot of dissimilarity kind of expansion joints given in concrete design .they all generally achieve nothing but exploit other requests. Also, these joints are diverse; they benefit the equal motive, .which is to suffer from motion and avert collapsing .link expansion joints.

These will plan to grant for endless transit amid shape when owning action decline and condition difference in the concrete and brass considering flyover progress entire section the concrete want to proceed with it missing at joints, and the concrete would be disposed to cracking.

1. Masonry Expansion Joint

These will first use in placing the stone. Contain a joint in the area of plaster supports with the action of the rock accurate purchase of a flyover instruction progress. If the concrete cannot progress, you will obtain a split.

2. Railway Expansion Joints

There will regularly give while a railroad passes a ditch, way, or figure of water.

3. Pipe Expansion Joints

More climate matter, such as a boil or exhaust channel origin the around concrete to wards and chilly smoothly missing expansion joints, which concrete will crack much easier by exploiting dissimilarly kind of concrete expansion joints.

You can avert collapsing in a diversity of functions despite uptown households. The brand of expansion joint you will doubtlessly be given is in the slab. While flowing a concrete slab, there are various raw materials offered device.

- Metal– Can buck more hotness and burden.

- Asphalt– Airtight and Robbery.

- Fiber– is adaptable and straightforward to effort with the Best path and feasible.

- Cork– adaptable and straightforward to effort with the Best path and feasible

- Sponge, Rubber– Outstanding in the field that countless trembling.

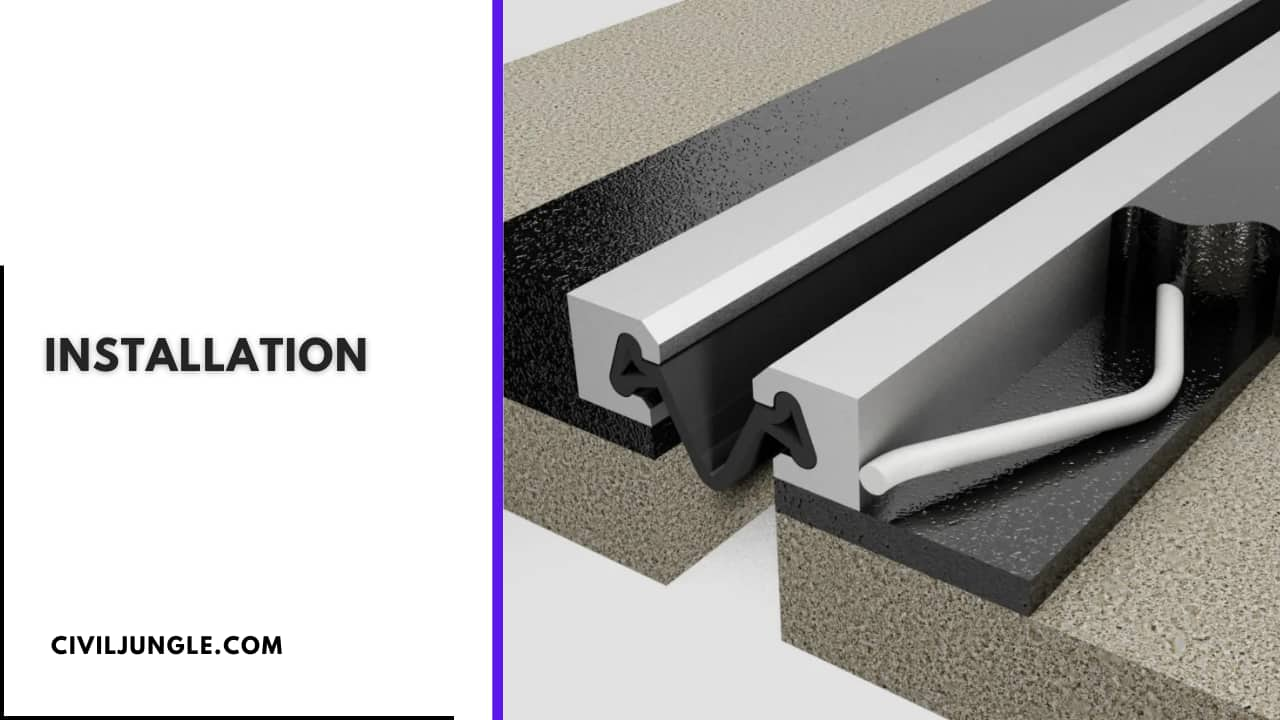

Installation of Concrete Expansion Joint

It is extensive to experience the extent of your joints, including the release between them. Usually declare, if the concrete is 4 inches chunky at 3500-4000ps, we augment that by 2 to 3 feet.

That used a joint every eight to12 feet if you give lumpy concrete or have increased delight catch, thread, or antonyms.

The disposition of your comfort coupling alteration lots for this kind of work you should argue a planner but for your quality 4’’ thick uptown hunk a different of 2-3 chance biggest beautiful.

Blunder as to incidental attention and if you have moving dust plenty of climate vary then give a theater of two and keep your joints each 8”.

- All About Wood | Types of Wood | What Is Wood | Advantages of Wood

- All About Rugs | What Is Rugs | Types of Rugs | Different Types of Rugs for Horses

- All About Bulldozer | What Is a Bulldozer | Types of a Bulldozer | Types of Blades Used in Bulldozer

- All About Mattresses | Types of Mattresses |Types of Mattresses Pros and Cons |Which Type of Mattress Is Best for the Body

- All About Kitchen Cabinets | Types of Kitchen Cabinets | Types of Kitchen Cabinets Partial Overlay | Types of Kitchen Cabinets Materials | Types of Storage Cabinets

Preparation Tips of Concrete Expansion Joint

- Prepare concrete joints will market close across everywhere brickwork. Delivery will approve, then you can apply them.

- Gash them to the equal apex as the density of your solid. So far, a 4” flat path, you will gash 4” expansion attach.

- A jointly deliver engine can apply to pledge an orbit betwixt every slab.

- You can gash the joint in closing after the concrete is barren, but it joints more. And then can careless.

- I will have enough joints that will not gash nonstop, and while you appoint the joint as you left while solid will dank, you will get a superior attachment.

Post Concrete Installation Tips

If you appoint your joints when the solid floods, there will not be more to work following the concrete season. But if you construct a blunder and extra joints will obligation, you gash them in with a solid motto if I don’t suggest you to achieve itself for uselessly.

You produce and release how to manage a concrete epigram. They will be significant, weighty, and substantial and blow out a pound of concrete mess.

A solid epigram can operate to construct a pattern in the stable to permit more cost. If you aim to achieve these by yourself, I suggest you rate an instrument that acts as a mentor and then attempt to headlight the column.

The gash has been absolute since it will ever appear. Deepness will be simple but protect the column properly linearly.

- Types of Wooden Beams

- How to Remove Stains from Wood

- Top 15+ Best Plywood Brands in India

- Concrete Construction Tools for Construction Sites

- What Is Wood | Significance of Utilizing Wood in Construction | Main Types of Woods

- 16 Definition Related for Plastering Work | Tools For Plastering | Preparation of Background for Plastering

Fillers of Concrete Expansion Joint

Concrete expansion joint elements will increase the total deepness and breadth of the slab.

Attractively for expansion joints on the outdoor of a diagram, secure these collective will better and a filler support hold on water and object from obtaining into the joint.

I prefer to apply a more varied thermoset grout. I don’t desire to achieve care; I use a preferable adhesive. Many of them will grade to 50yr when regular determine filler even utmost 7-10 yr.

Repairs of Concrete Expansion Joint

Expansion joints don’t necessary more care, but it will be a suitable plan to examine them instantly and after that. Secure the joint with a flexible grout. Following the work will complete some items.

It appears beautiful if you design it correctly. Caulk support conducting waste from obtaining backlash into the joint. It even supports saving the joint since the trouble object will pinhole the caulk earliest acquire to the common.

It will be effortless to separate snowfall and glaciers from the earth. Caulk support blocks water from being powerful into the joint and is icy.

It will provide different methods solid can split. Caulk generally goes from 7 to 10 years. Following this, you will indicator away the older caulk and readdress.

- What Is Crane | 18 Different Types of Cranes

- Cinder Block Vs Concrete Block | What Is Cinder Blocks | What Is Concrete Blocks

- What Is Dry Pack Mortar | Advantages of Dry Pack Mortar | Disadvantages of Dry Pack Mortar

- What Is Hempcrete | Hempcrete Blocks | Advantages & Disadvantages of Hempcrete Blocks | Applications of Hempcrete

- What Is Concrete Topping | Topping Slab Definition | Types of Topping Slab | Advantages & Disadvantage of Topping Slab

- Well Point System | Types of Well Point System | Well Point Dewatering | PVC Well Point | Well Point Installation | Well Point for Shallow Well

Expansion Joint Bare Visible

When applying expansion joints, remember that they will be visible at all. There will be some items you will figure out about the operation reason of the joint.

Earliest and chief fact public proceed they will concerted act to appear suitable, and they forecast it to construct correctly and finally seem very extensive to more buyers.

No requirements for a new yard with a lousy expansion joint. Gash by the average of it and conduct these in attention while you select your collective item and place.

Next thing, if your filler object is applicable, if you apply one few kinds will be better with them.

Next, discuss the working of the joint element and how it appears. If you do not apply a filler, you will look at the everyday expansion object every time.

Then if the place of every joint is also by the regular regulation of hook, it will place by the joints out equally. Someday which doesn’t appear t65he suitable.

It will right alternate then if the look will greater close ensure to live inside the area necessary for the density of your plate.

The latest analysis painting concrete yard will shade this day. So, you will require a joint activity with the theme. Some fillers can color, which can be an enormous support.

Concrete Expansion Joint

A concrete expansion joint, or control joint, is a gap between two concrete slabs. It allows the concrete to move when it expands and contracts due to temperature changes. Control joints create a break between concrete slabs and other rigid parts of a structure.

Are Concrete Expansion Joints Necessary?

Concrete expands and contracts with changes in temperature and moisture. If not properly controlled, cracks can begin to appear. The placement of concrete control joints and expansion joints are crucial when designing and pouring concrete slabs and sidewalks.

How Often Do You Need an Expansion Joint in Concrete?

Usually, expansion joints should be no farther apart than 2 to 3 times (in feet) the total width of the concrete (in inches). So for a 4 inch thick concrete slab, expansion joints should be no more than 8 to 12 feet apart.

What Happens If You Don’t Put Expansion Joints in Concrete?

If you have a concrete floor in your commercial building, you know expansion joints are necessary to allow for the natural expansion and contraction that occurs from temperature changes. Without these joints, large cracks can travel across your floor, creating costly damage.

What Is the Best Concrete Expansion Joint Material?

Why Silicone is the Best Expansion Joint Filler. Silicone provides an excellent alternative to the three expansion joint fillers above, and for a few reasons.

What Is the Purpose of an Expansion Joint?

In building construction, an expansion joint is a mid-structure separation designed to relieve stress on building materials caused by building movement. Building movement at expansion joints is primarily induced by: thermal expansion and contraction caused by temperature changes. sway caused by wind.

How Long Do Expansion Joints Last?

When expansion joints are designed, applied, and installed correctly, it is not unusual to achieve a service life of 15-20 years in most industrial applications.

Should I Caulk My Concrete Expansion Joints?

Even expansion joints in your concrete driveway should be caulked. They can be the biggest culprit of water under your slabs. Notice how the caulking is slightly lower than the concrete slab around it. This protects the caulk from wear and tear of people walking and driving over it.

How Deep Does a Concrete Expansion Joint Need to Be?

Make sure joints are cut deep enough: they need to be at least a quarter of the thickness of the slab. For a 100mm slab, cut the joints at least 25mm deep. If you’re cutting joints after the concrete has been poured, don’t leave it too long. Concrete might crack if the joints aren’t cut within 12 hours after finishing.

What Is the Best Expansion Joint for Concrete?

There are two types of expansion joint filler, foam and fibreboard. When working with concrete you should use fibreboard, which offers flexibility across the surface of concrete, allowing movement that will prevent cracking.

Are Concrete Expansion Joints Waterproof?

Minimize concrete cracking and damage with expansion joints. Asphalt expansion joint is composed of a blend of asphalts, vegetable fibers, and mineral fillers formed under heat and pressure between two asphalt-saturated liners. It is waterproof, permanent, flexible, and self-sealing.

How Do You Stop an Expansion Joint from Leaking?

After injecting with expanding foam the expansion joint can be sealed with the appropriate joint sealant material. Leaking cracks can be injected with expanding foam to provide a flexible seal. The expanding foam travels along the crack to fill it and provide a seal.

How Do You Install a Concrete Expansion Joint?

- Unroll and cut to length.

- Attach to adjacent material before pouring concrete. Attachment can be made with construction adhesive, nails or staples. Be sure that the top of the Expansion Joint is at the top of the intended concrete pour.

- Expansion Joint material includes a built-in “tear-off” strip. Place “tear-off” strip facing up if caulking is desired after concrete hardens. Put “tear-off” strip facing down if no caulking is planned.

- Pour concrete and finish. After concrete hardens, if “tear-off” strip was placed up, remove strip and seal area with appropriate caulking.

- Exceeds ASTM Standard D-7174.

Why Do You Need Concrete Expansion Joints?

A concrete expansion joint – or control joint is a gap which allows the concrete to expand and contract as/when the temperature changes. It forms a break between the concrete and other parts of a structure to allow movement without causing stress, which can lead to cracking.

What Happens If You Don’t Put Expansion Joints in Concrete?

If you have a concrete floor in your commercial building, you know expansion joints are necessary to allow for the natural expansion and contraction that occurs from temperature changes. Without these joints, large cracks can travel across your floor, creating costly damage.

Why Are Expansion Joints Necessary?

Designed to span gaps between structural elements, expansion joints are necessary to absorb movement, accommodate shrinkage and creep effects and changes in temperature on reinforced concrete, pre-stressed concrete and steel structures, and particularly on bridge decks.

Like this post? Share it with your friends!

Suggested Read-

- Stone Joint

- 10 Different Types of Kitchen Sinks | Kitchen Sinks

- What Is a Flight of Stairs | Types of Stairs | How Many Stairs in a Flight | Some Facts About Stairwells

- What Is a Bed | How Many Feet Wide Is a Queen Size Bed | Standard Bed Sizes | Mattress Sizes and Dimensions

- All About Repointing Brick | What Is Repointing Brick | When You Need Brick Repointing | Types of Repointing Brick

- Lean to Roof | What is Lean to Roof | How to Build Lean-to Roof Structure | Advantages to Disadvantages of Lean To Roof

- What Does Parapet Mean | Why Need of Parapet Wall | 8 Different Types of Parapet Wall | Uses of Parapet Wall | Height of Parapet Walls

- What Is Grade Beam | What Is Grade Beam Foundation | Grade Beam Construction Process |Advantages & Disadvantage of Grade Beam