Introduction of CMU Wall

CMU is a modern building unit that has various benefits as compared to bricks. The CMU blocks are available in various shapes and sizes in the market and are widely used in the construction of walls of the building.

In this article, we will discuss all about the concrete masonry units.

What is CMU Wall?

The CMU wall is constructed with the help of standard sizes concrete masonry units. A concrete masonry unit (CMU)is a versatile and environment-friendly building unit that is available in a variety of shapes and sizes in the market.

The Full form of the CMU is Concrete Masonry units. The CMU walls act as load-bearing walls which are widely used in the construction of residential as well as commercial buildings. The concrete masonry unit has a rectangular shape.

The concrete masonry units have an interlocking system that gets fitted into each other. The concrete blocks are interlocked with the help of interlocking tongues and grooves.

The CMU Walls are comprising of steel as a reinforcement and other types of composite materials.

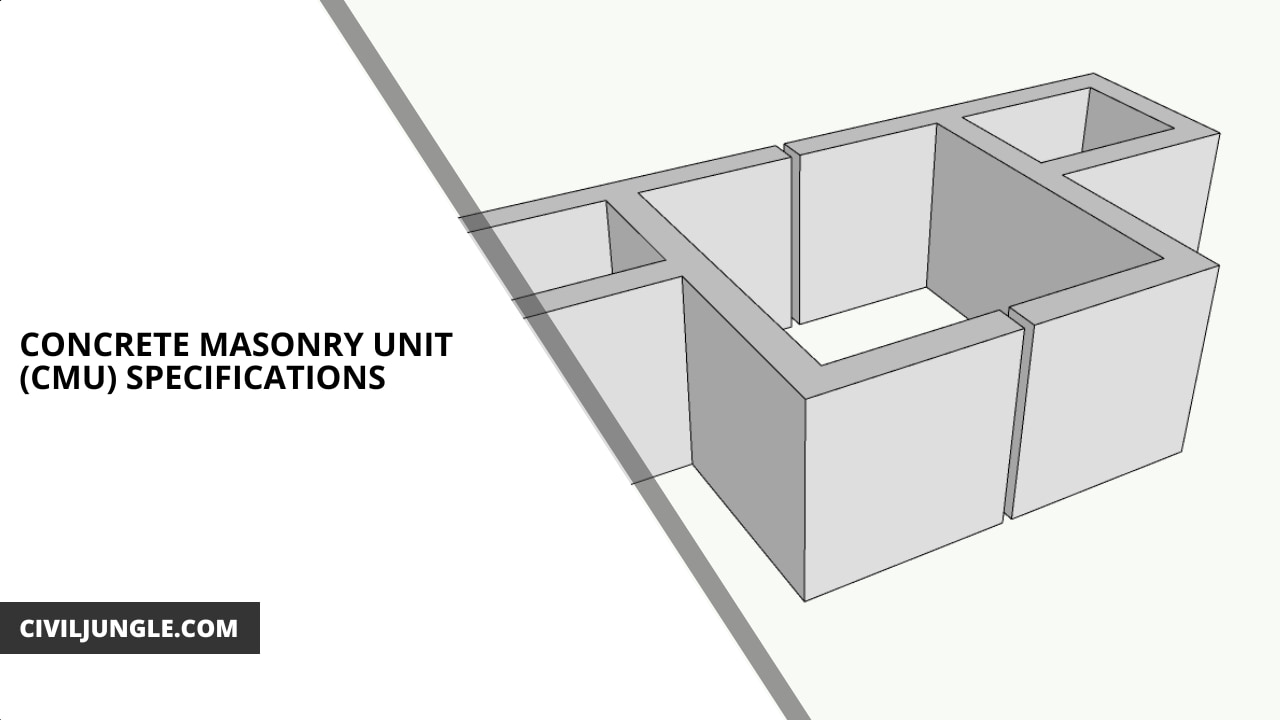

Concrete Masonry Unit (CMU) Specifications

The manufacturing process of the concrete masonry units should be as per the standards given by the American Society of Testing and Materials (ASTM).

Following are the standards which are given by the American society for testing and materials.

Designation of ASTM |

Types of Concrete Masonry Unit |

| ASTM C55 | Concrete Bricks |

| ASTM C73 | Calcium silicate face brick |

| ASTM C90 | Load bearing Concrete masonry units |

| ASTM C139 | CMUs for construction of Catch Basins and Manholes |

| ASTM C744 | Calcium Silicate Masonry Units and prefaced concrete |

| ASTM C936 | Solid interlocking concrete paving units |

| ASTM C1372 | Segmental Retaining wall units |

Concrete Masonry Units (CMU) Shapes

The CMU concrete units are available in various shapes in the market which are as follows.

- Single corner unit: – The single corner unit has only one end which is squared off. It is generally used at the end of the wall where the end of the block is exposed.

- Stretcher Unit: – The stretcher unit has a flange extension on both of its ends. It is generally used in the middle of the walls where both ends are covered by the adjoining bricks.

- Double corner unit: – The Double corner unit has two ends that are squared off. This type of block is generally used to create vertical pillars.

- Sash units: – Sash units have slots cut in the flat ends. These are used around the windows and door openings to provide the expansion space.

- Cap Units: – The Cap units are the solid and thin concrete blocks that are generally used to open the cavities at the top of the concrete block walls.

- Bullnose blocks: – The bullnose blocks are also available in the market with one end rounded.

These all are the various shapes of the concrete masonry units which are available according to the requirement and the design of the construction projects.

CMU Wall Details (Concrete Masonry Units)

The concrete masonry walls get manufactured from the precast concrete and it is the most versatile building unit which is very easy to construct.

The construction done with the concrete masonry unit is very fast. The CMU walls required very less maintenance and they are more durable.

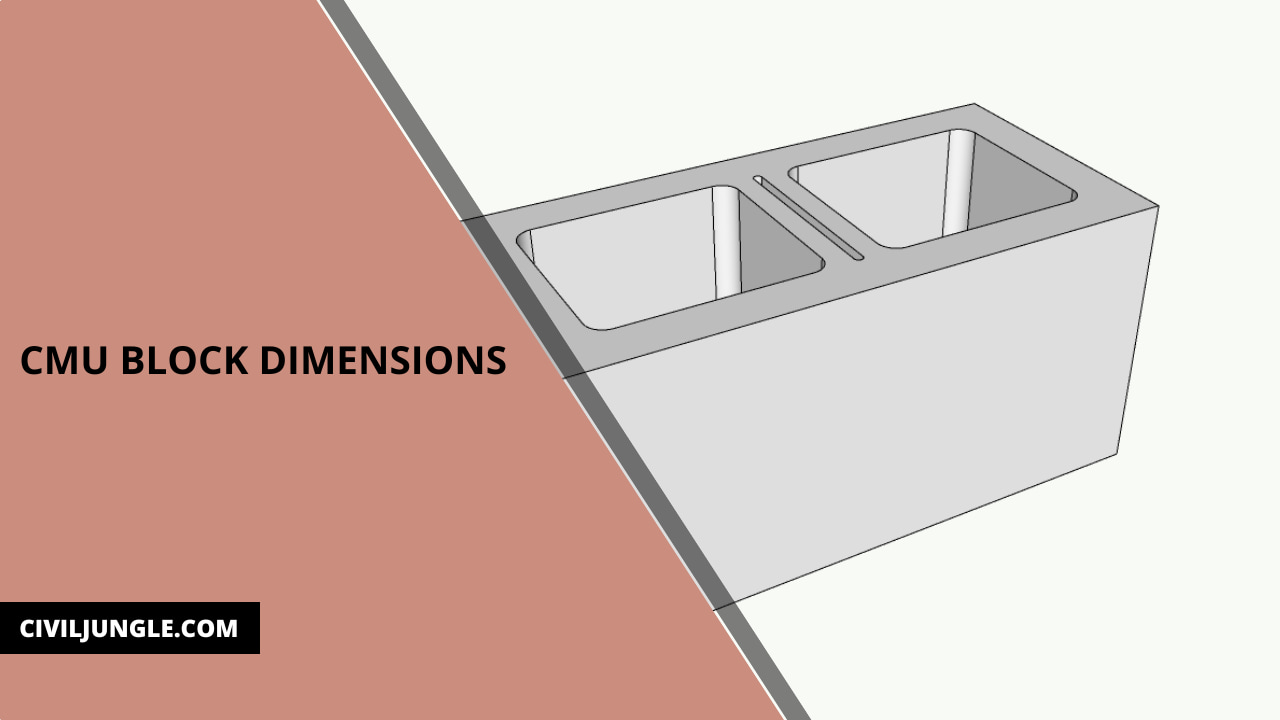

CMU Block Dimensions

Concrete Masonry blocks are available in various sizes in the market. The concrete masonry blocks are also available in the half sizes due to which the end of the corner of the walls can be constructed accurately.

The concrete masonry blocks are identified with their depth and the thickness of the wall. The nominal dimensions of the concrete masonry blocks are given below in the tabular format.

CMU or cinder Block Weight. The concrete masonry blocks are made with a mixture of Portland cement, sand, aggregate, and water in the appropriate proportion

Sizes of the CMU Blocks |

Nominal Dimensions of the CMU Blocks |

| 4” Full Blocks | 4” x 8” x 16” |

| 4” Full Blocks | 4” x 8” x 8” |

| 6” Full Blocks | 6” x 8” x 16” |

| 6” Full Blocks | 6” x 8” x 8” |

| 8” Full Blocks | 8” x 8” x 16” |

| 8” Full Blocks | 8” x 8” x 8” |

| 10” Full Blocks | 10” x 8” x 16” |

| 10” Full Blocks | 10” x 8” x 8” |

| 12” Full Blocks | 12” x 8” x 16” |

| 12” Full Blocks | 12” x 8” x 8” |

CMU or Cinder Block Weight

The weight of the cinder blocks or Concrete masonry units mainly depends upon the density of the concrete used in the manufacturing of the concrete blocks.

The concrete block units are classified into three categories according to their weight

- Lightweight CMU Blocks: The weight of the lightweight cinder blocks is less than 105 fb/ft3.

- Medium weight CMU blocks: The weight of the medium weight concrete masonry blocks ranges between 105 fb/ft3 to 125 fb/ft3.

- Normal weight CMU blocks: The weight of the normal weight CMU blocks is more than 125 fb/ft3.

CMU Blocks Compressive Strength

The compressive strength is one of the most important criteria which should be tested before using any construction material or building unit. The concrete masonry walls have compressive strength which ranges from 7MPa up to 35 MPA.

The compressive strength of the concrete masonry unit mainly depends upon the mix design and the quality of concrete used in the manufacturing of the concrete masonry blocks.

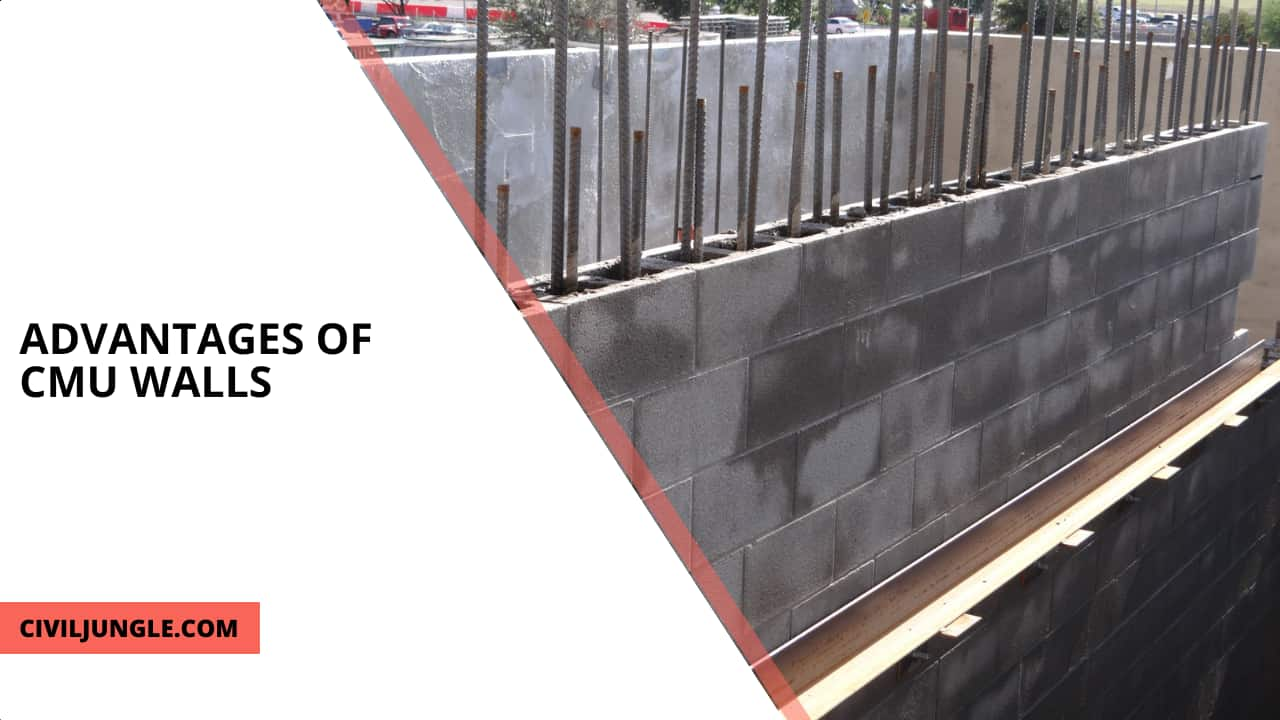

Advantages of CMU Walls

- There are various advantages of CMU walls which are as follows

- The concrete masonry unit walls are more durable as compared to the brick walls. The concrete masonry units are very easy to install and require very little maintenance. The CMU walls have good resistance to fire.

- The construction of the CMU Walls is economical as compared to the brick walls.

- The concrete masonry units are larger than conventional bricks.

- The steel reinforcement is also used in the CMU walls which increases the load-bearing capacity of the CMU walls.

- CMU walls are best suitable for areas with aggressive environmental conditions.

Disadvantages of CMU Walls

There are also some disadvantages of CMU wall construction which are as follows

- The concrete masonry unit does not have good resistance to water penetration.

- The concrete masonry blocks require an additional coat to its surface to make it water-resistant which increases the cost.

- Concrete masonry blocks have less thermal resistance.

Applications of Concrete Masonry Unit

Concrete masonry units have wide applications in construction which are as follows

- The concrete blocks are used in the construction of the foundation walls and the basement walls.

- The concrete masonry blocks are also used for the decorative purpose which will enhance the aesthetical view of the structure.

- CMU is also used in the construction of the exterior walls as well as partition walls.

CMU Wall Construction

The step by step process of the CMU wall construction are as follows

1. Marking of the Layout of the Foundation

The first step before starting the CMU wall construction is marking the layout of the foundation on the ground with lime as per the design plan. The layout of the complete building should be marked on the ground.

2. Excavation

The next step after the marking of the foundation is to excavate the earth for the construction of the foundation. The depth of the excavation on the ground depends upon the design of the foundation.

3. Construction of the Foundation

The CMU walls should be rest on the firm foundation. The footing should be constructed at the required depth. The foundation should be constructed and poured with concrete. It is necessary that sufficient curing of the foundation should be done.

4. Construction of CMU Wall

The suitable size and the shape of the concrete masonry blocks should be selected as per the requirement and the design of the CMU walls.

CMU walls are constructed with different types of blocks such as stretchers and corner units. Each layer of the joint should be properly connected with each other.

5. Addition of the Reinforcement

The only wall constructed with the concrete masonry units cannot able to resist the tensile stresses which may lead to cracking. The horizontal, as well as the vertical steel reinforcements, should be added to the CMU walls.

6. Finishing of the Joints

The joints of the CMU Walls should be properly finished with the help of mortar.

CMU Block Cost

The cost of the CMU blocks ranges from $3 to $5 per square foot. The labor and the installation cost of the concrete masonry units is around $10 to $12.

The concrete masonry units with less weight are less expensive than the high density CMU blocks. Lightweight concrete blocks require less cost for its installation.

FAQs about Concrete Masonry Units (CMU) Walls

What Is a Cmu Wall?

A CMU wall is a type of wall constructed using Concrete Masonry Units (CMUs), which are versatile and environment-friendly building blocks. CMUs come in various shapes and sizes and are used in both residential and commercial construction for load-bearing and non-load-bearing walls.

What Are the Common Sizes of Cmu Blocks?

CMU blocks are available in several nominal sizes including:

- 4” x 8” x 16”

- 6” x 8” x 16”

- 8” x 8” x 16”

- 10” x 8” x 16”

- 12” x 8” x 16”

They are also available in half sizes for more precise construction.

What Are the Standard Specifications for Cmus?

CMUs are manufactured according to standards set by the American Society for Testing and Materials (ASTM). Common designations include:

- ASTM C55: Concrete Bricks

- ASTM C90: Load Bearing Concrete Masonry Units

- ASTM C139: CMUs for Catch Basins and Manholes

- ASTM C936: Solid Interlocking Concrete Paving Units

What Are the Advantages of Using Cmu Walls?

Advantages of CMU walls include:

- Durability and low maintenance

- Fire resistance

- Cost-effectiveness

- High load-bearing capacity due to steel reinforcement

- Suitability for aggressive environmental conditions

Are There Any Disadvantages to Cmu Walls?

Disadvantages include:

- Poor resistance to water penetration

- Additional cost for water-resistant coatings

- Lower thermal resistance compared to some other building materials

What Types of Cmu Blocks Are Available?

CMU blocks come in various shapes including:

- Single Corner Units

- Stretcher Units

- Double Corner Units

- Sash Units

- Cap Units

- Bullnose Blocks

How Is a Cmu Wall Constructed?

The construction process typically involves:

- Marking the layout of the foundation

- Excavation and foundation construction

- Building the CMU wall with selected block types

- Adding reinforcement for strength

- Finishing the joints with mortar

What Is the Cost of Cmu Blocks?

The cost of CMU blocks ranges from $3 to $5 per square foot. Labor and installation costs add approximately $10 to $12 per square foot. Lightweight CMUs are generally less expensive than high-density blocks.

How Does Cmu Block Weight Affect Its Use?

CMU blocks are classified based on their weight:

- Lightweight (<105 lb/ft³)

- Medium weight (105–125 lb/ft³)

- Normal weight (>125 lb/ft³)

The weight impacts the block’s cost and ease of handling.

What Are Some Common Applications of Cmu Walls?

CMU walls are used in:

- Foundation and basement walls

- Exterior and partition walls

- Decorative purposes to enhance aesthetic appeal