Introduction of Built-Up Roof with Gravel

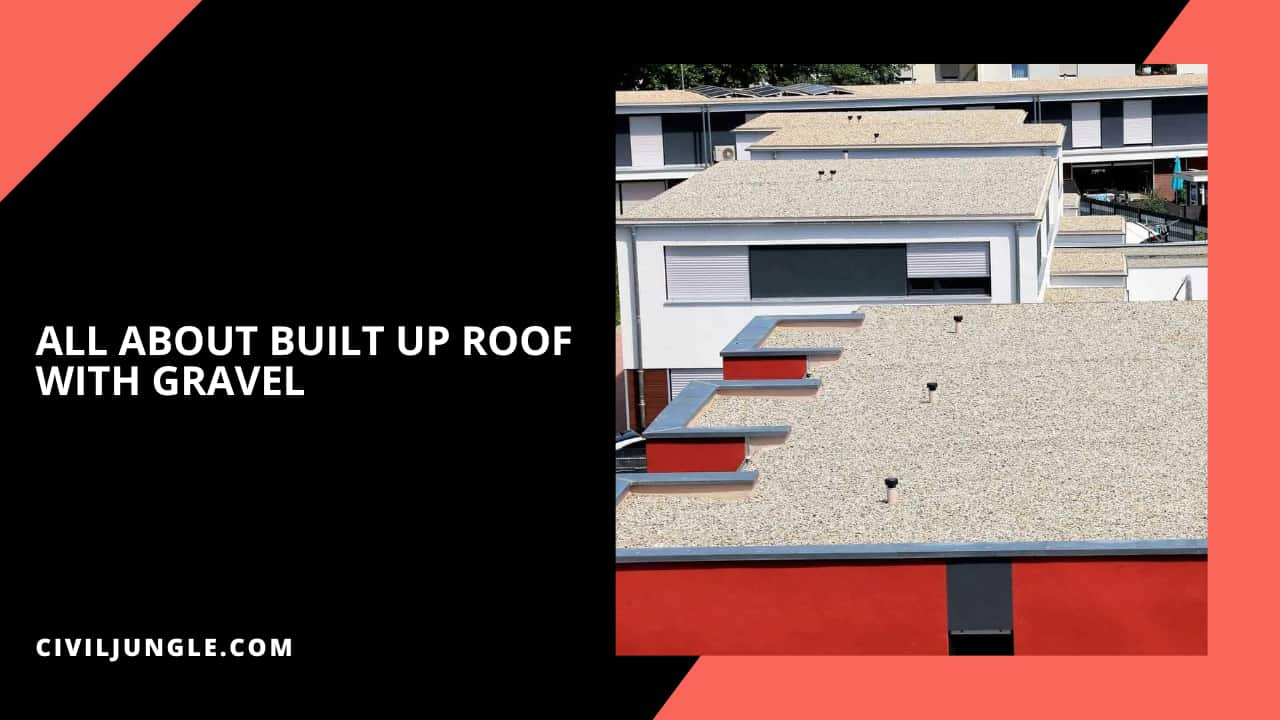

BURs (also known as tar and gravel roofs) are a well-known and popular form of flat roof made composed of alternating layers of roofing felt or fibreglass and asphalt that is placed using heat, resulting in a long-lasting and robust roofing system.

The gravel buried in the flood coat protects the underlying layers from the elements, including ultraviolet rays and natural dangers such as roof hail damage or severe rains. Depending on the underlying strata, the construction of the building, and the climate of the area, different types and weights of gravel are required for different types of BURs.

This leads to the common query, why do roofs have gravel? Despite the fact that the asphalt waterproofs the roof (especially essential for flat roof gravel surfaces where water can accumulate), the gravel layer increases the life of the roof.

It’s worth noting that the “gravel” is generally some form of aggregate material, such as pea gravel, slag, or mineral granules that are pea-sized and roughly a quarter-inch thick, and that it’s used to fulfil the Class A surface burning categorization.

There are various advantages to having a tar and gravel roof. They typically have a life expectancy of 20 to 25 years, based on the region as well as the remaining of the homeowner’s building (barring any major natural disasters of course).

The weather resistant properties of the crushed rock embedded in the roof could indeed help to avoid damage such as cracking or blistering, which can ultimately led to leakages or even other problems over time.

Modifiers are got to add to standard roofing asphalt to replace plasticizers deleted during in the distillation process, resulting in bitumen roofing systems. To boost its strength and durability, it would then be reinforced with fibreglass or polyester fibre matting. SBS (styrene-butadiene-styrene) as well as APP (atactic polypropylene).

SBS increases the roofing membrane’s elasticity, allowing for more contraction and relaxation, whereas APP increases the roofing system’s capacity to remain robust as it matures. Each type is common in modern climates and purposes, and an expert roofing contractor in the area can help you decide which is best for your home.

There are numerous advantages to choosing a modified bitumen roof. The gravel absorbs as well as heats up and aids in evaporation of water, pushing heat and moisture away from its original layer. For those wondering how to put gravel on flat roof, whenever the team needs to reach the roof or contractors are doing repairs, the looser gravel helps to give a better grip for foot traffic.

It should be noted that the gravel on modified bituminous roofing systems should be maintained reasonably flat on the roof at any and all moments, and part of the gravel must stay loose to avoid damage or punctures from foot activity.

Why Do They Put Gravel on Flat Roofs?

Many flat-roof (low-slope) commercial buildings have gravel on top of their roofs. This brings up the question, why gravel on roof? or why is there gravel on roofs?

Gravel is used on flat roofs for three reasons:

- To safeguard the underlying layer of roofing materials, as is the case with built-up roofs (BURs).

- To weigh down or secure the roofing material, as with single-ply flat roofs.

- For these goals, different types and weights of gravel are utilized on flat roofs.

Gravel to Protect Built-Up Roofs

A built-up roof (BUR), often known as a tar-and-gravel roof, is a tried-and-true gravel for flat roof type. To build a long-lasting roof system, alternating layers of roofing felt (typically fiberglass) and hot-applied asphalt are used.

To protect the roof from the elements, particularly ultraviolet (UV) radiation and hail, a layer of gravel, or small stones, is applied on top of the final coat of asphalt. The gravel is incorporated in the top coat of asphalt (known as a flood coat), which aids in the retention of the gravel.

The best gravel for flat roof as a weatherproofing layer extends the life of the roof’s surface by preventing issues like cracking and blistering. Although the asphalt waterproofs the roof (which is critical for flat roofs), the gravel adds a vital, life-extending layer. Although commonly referred to as “gravel,” the top layer is usually some sort of aggregate material (such as pea gravel, slag, or mineral granules).

BUR aggregate is usually pea-sized, about a quarter-inch thick, and is used to impart the Class A surface burning designation in accordance with mandatory ASTM E108, UL790, or CAN/ULC S107M requirements.

Purpose of Gravel on a Flat Roof

The usage of a ballasted commercial roofing system is primarily motivated by two factors: Because of the weight given by the gravel, the roof materials are anchored to the decking with much fewer fasteners. Using a specially designed screw and plate fastening arrangement, the gravel may be put in a lot less time.

The ballast keeps the roofing system cool and out of the sun’s damaging rays, reducing energy expenditures. Heavy foot activity and high-wind situations are also no match for the gravel top coat. Despite the benefits of a ballasted roof system, there are certain drawbacks to be aware of. It is critical to remember that the amount of gravel added to a commercial roof must be precise.

It is determined by the roofing specification utilised and the type of structure. Gravel that is too heavy can cause structural problems. The weight of a gravel-coated roof should be between 10 and 25 pounds per square foot.

Finding a leak amid a sea of gravel can be challenging, especially if the gravel is embedded in a layer of hot asphalt. Because gravel retains dirt and moisture, patching leaks once they’ve been found can be challenging. Ballasted roof systems are still a viable option for today’s commercial roof demands, even if they aren’t as popular as they once were.

Added Benefits of Bur Flat-Roof Gravel

The coating of gravel on a BUR flat roof may both assist water evaporate and keep heat away from the underlying roof structure since it stores and releases heat. When doing maintenance or repairs, the gravel gives a stronger grip for foot traffic.

The gravel also serves as a barrier to prevent natural material (such as leaves) from moving towards and clogging the flat roof’s drains, retaining them instead. Modified bitumen roofs are made out of a combination of asphalt and rubber with a coating of gravel placed in the top layer to give UV protection. There is no need for extra gravel on the roof.

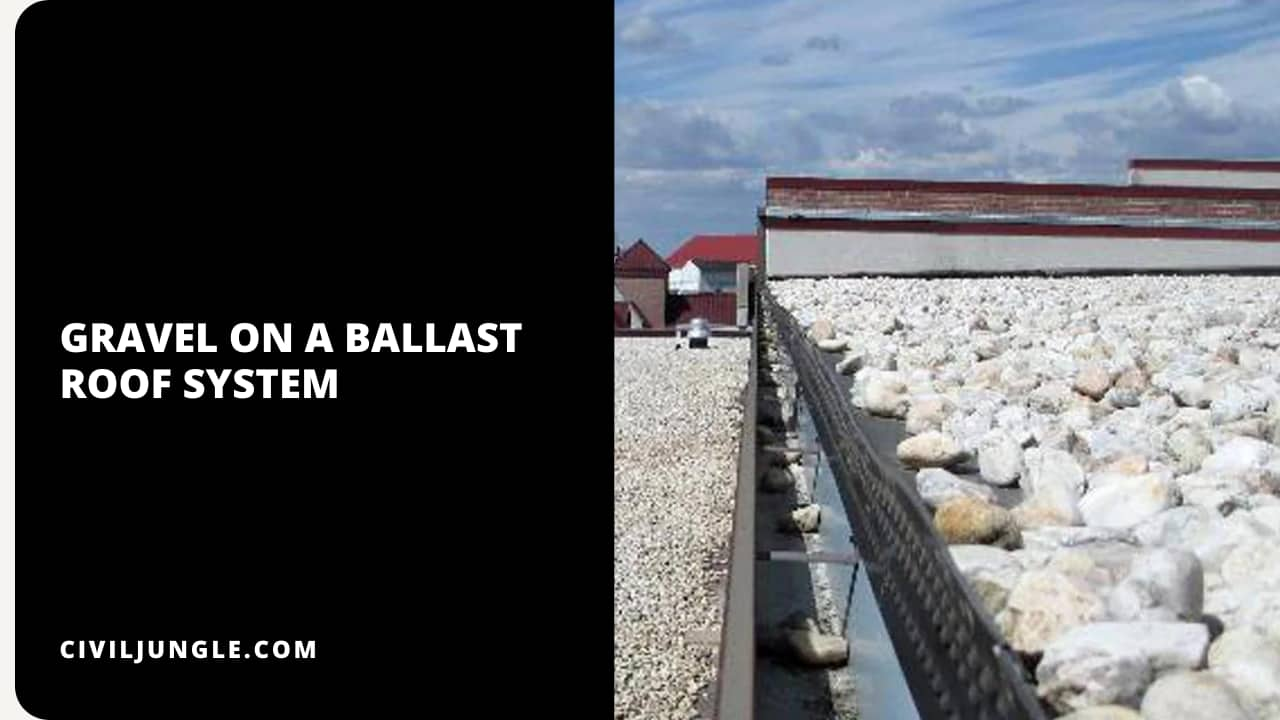

Gravel on a Ballast Roof System

Ballast is a kind of gravel that is used in single-ply roofing systems. Although the primary function of ballast is to weigh down roofing materials, it also provides the same protective advantages as indicated above.

Ballast is widely used with single-ply flat roofs built of tar-and-gravel replacements such as ethylene propylene diene monomer (EPDM), polyvinyl chloride (PVC), and thermoplastic polyolefin (TPO).

Single-ply roofing materials are not self-adhering or bonded together in any way. Ballast is required for weight to protect the roof from severe winds since nothing ties the waterproofing membrane to the roofing components beneath.

Ballast is not the same as BUR protecting gravel. Ballast stones are typically one to two inches thick and used more liberally than on a built-up roof. Wind gusts are significantly reduced by the heavier stones.

A ballast system reduces roof system application costs since it takes less time to install because the layers are not sealed together. Ballasted flat roofs are a common choice, particularly for commercial structures.

Additional Benefits of Ballast on a Flat Roof

A ballasted roof’s gravel absorbs heat, keeping the sun from heating the roof materials below and making the roof more energy-efficient. Although single-ply roofs are naturally sun-protective, ballast adds an extra layer of protection from UV radiation. During repair or maintenance operations, ballast also protects against hail and foot traffic.

Because the ballast stones are “loose-laid,” rather than entrenched in a layer of tar (asphalt), they are easily moved for repairs or maintenance.

1. Open Joints:

To repair split joints or seams, place some cement under the open seam and hold it down so it may stick to the substrate. If this fails, cut a huge piece of felt and lay it over the open joint. Nail it down, then cover the nails with roofing cement. Finally, put gravel over the cement and allow it to cure.

2. Blisters:

Small blisters can be readily treated by cutting the blister with a knife. Allow as much time as possible for the area to dry. If the top layers are wet, continue cutting down until you reach a dry layer. Remove the felts (plies) and replace them with new felt. Cover the asphalt with chippings once it has been applied. If chippings aren’t accessible, you can utilise liquid-applied coatings on top of the repaired region.

3. Undulations or Waves:

Repair built-up roofing undulations by simply layering on top of the affected region to level it. Before doing any repairs, make sure the substrate is in good shape.

4. Cracks:

Cracks in the asphalt should be simple to repair. To begin, clear the area of any gravel or debris. Apply an asphalt cement layer to the surface and cover it with roofing felt. To ensure that you’ve covered the whole area, make sure there’s at least 4 inches of overlap. Apply a final coat of asphalt cement and repeat the process. Cover the cement with gravel.

Frequently Asked Questions (FAQ)

What Is a Built-Up Roof (Bur)?

A Built-Up Roof (BUR) is a type of flat roofing system made from multiple layers of roofing felt or fiberglass, combined with asphalt. The layers are applied using heat, creating a durable and long-lasting roof. A layer of gravel is added on top for additional protection.

Why Is Gravel Used on Bur Roofs?

Gravel is used on BUR roofs primarily to protect the underlying layers from UV rays, hail, and other environmental factors. It also helps to prevent damage such as cracking and blistering, thereby extending the life of the roof.

What Types of Gravel Are Used in Bur Systems?

Typically, the gravel used in BUR systems is pea gravel, slag, or mineral granules. The gravel is usually pea-sized, about a quarter-inch thick, and is chosen to meet specific fire resistance standards, such as Class A surface burning.

How Does Gravel Affect the Longevity of a Bur Roof?

Gravel helps extend the life of a BUR roof by providing a protective layer that shields the asphalt from weather damage and UV exposure. This can help prevent issues like cracking and blistering that could lead to leaks over time.

What Are the Benefits of Using a Bur Roof with Gravel?

The main benefits include excellent weather resistance, durability, and a long lifespan of 20 to 25 years. Gravel also helps with heat absorption and moisture evaporation, and provides a better grip for foot traffic during maintenance.

What Is the Difference Between Bur Gravel and Ballast Gravel?

BUR gravel is used primarily to protect the roof and extend its life, while ballast gravel is used to weigh down single-ply roofing materials to prevent wind uplift. Ballast stones are usually larger and thicker compared to BUR gravel.

How Is Gravel Maintained on a Bur Roof?

Gravel should be maintained relatively flat on the roof to avoid damage. It is important to ensure that some gravel remains loose to prevent punctures and damage from foot traffic.

What Should I Do If I Find a Leak in a Gravel-Covered Bur Roof?

Finding and repairing leaks can be challenging due to the gravel. For open joints, apply roofing cement and cover with gravel. For blisters or cracks, cut and dry the affected area, replace damaged felts, and cover with new asphalt and gravel.

Can Bur Roofs with Gravel Be Used in All Climates?

Yes, BUR roofs with gravel can be used in various climates. The choice of gravel type and weight might vary based on the local weather conditions and building requirements.

Are There Any Drawbacks to Using a Bur Roof with Gravel?

One potential drawback is the difficulty in locating and repairing leaks due to the gravel layer. Additionally, the weight of the gravel must be carefully managed to avoid structural issues.