What Is Bar Bending Schedule?

Bar bending is calculating steel quantity that calls bar bending schedule. The preparation of bar bending schedules is one of the final stages in any concrete design following the preparation and detailing of the working drawings.

Whereas the procedure is generally straightforward, it does require a certain amount of calculation which can readily be carried out with the aid of a computer program. The program in this section calculates the lengths of reinforcing bars required and outputs a bar bending schedule table together with the total weight of steel.

Format of Bar Bending Schedule as per Code IS:2502-196

| Location | Mark Designation | Size and Type | Number Per Set | Number of Sets | Total Number | Length | Shape ( All Dimensions Are in Accordance with This Standard Unless Otherwise Stated) |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) |

| Column | C4 4R 25 N | MS Road 25 mm | 5 | 4 | 20 | 3000 | Straight |

Bar Bending Schedule Use Formulas

1. Unit Weight of Steel Bars

Density = Mass (weight of steel) / Volume

- Density = 7850 Kg / m3 Steel Bar

- Mass = Weight of Steel

- D = Dia of Bar in mm

- L = Lenght of M

- Volume = πD2 /4 x 1000 mm

- Weight of Steel = (7850) x (πD2 x L/4 )

- Weight of Steel = (7850/1000 x 1000 x 1000 ) x ( 3.14 D2 /4 )

- Weight of Steel = (785

0/1000x 1000 x1000) x ( 3.14 D2 x1000x/4 ) - Weight of Steel = 0.00785 x 0.785 D2

- Weight of Steel =0.00616225 x D2

- Weight of Steel = (0.00616225/1) x (D2 /1 )

- Weight of Steel = D2 / 162.27 kg/m

Example of 12 mm dia bar steel weight

Op-1 of calculation steel weight

- Weight of Steel = D2 / 162.27 mm

- Weight of Steel = 122 / 162.27 mm

- Weight of Steel = 144 / 162.27 mm

- Weight of Steel = 0. 8874 Kg/m

Op-2 of calculation steel weight

- Weight of Steel = (7850) x (π122 x L/4 )

- Weight of Steel = (7850/1000 x 1000 x 1000 ) x ( 3.14 122 /4 )

- Weight of Steel = (785

0/1000x 1000 x1000) x ( 3.14 122 x1000x/4 ) - Weight of Steel = 0.00785 x 0.785 122

- Weight of Steel =0.00616225 x 144

- Weight of Steel = (0.00616225 x 144)

- Weight of Steel = 0.8874 Kg/m

2. Plan Bar Length

3. Bends and Hooks Forming End Anchorages ( As per IS 2502:1963 )

Here

- k in 2 in the case of Mild Steel conforming, ( As per IS 2502:1963, P-6, Note-1 )

- k in 3 in the case of Medium Tensile Steel conforming, ( As per IS 2502:1963, P-6, Note-1 )

- k in 4 in the case of Cold-worked Steel conforming, ( As per IS 2502:1963, P-6, Note-1 )

Most IMP (As per IS 2502:1963, P-6, Table-II, Note )

- H = Hook allowance taken as 9d, 11d, 13d, and 17d for k values 2, 3, 4 and 6 respectively and rounded off to the nearest 5 mm, but not less than 75 mm.

- B = Bend allowance is taken as 5d, 5.5d, 6d, and 7d for k values 2, 3, 4 and 6 respectively and rounded off to the nearest 5 mm, but not less than 75 mm.

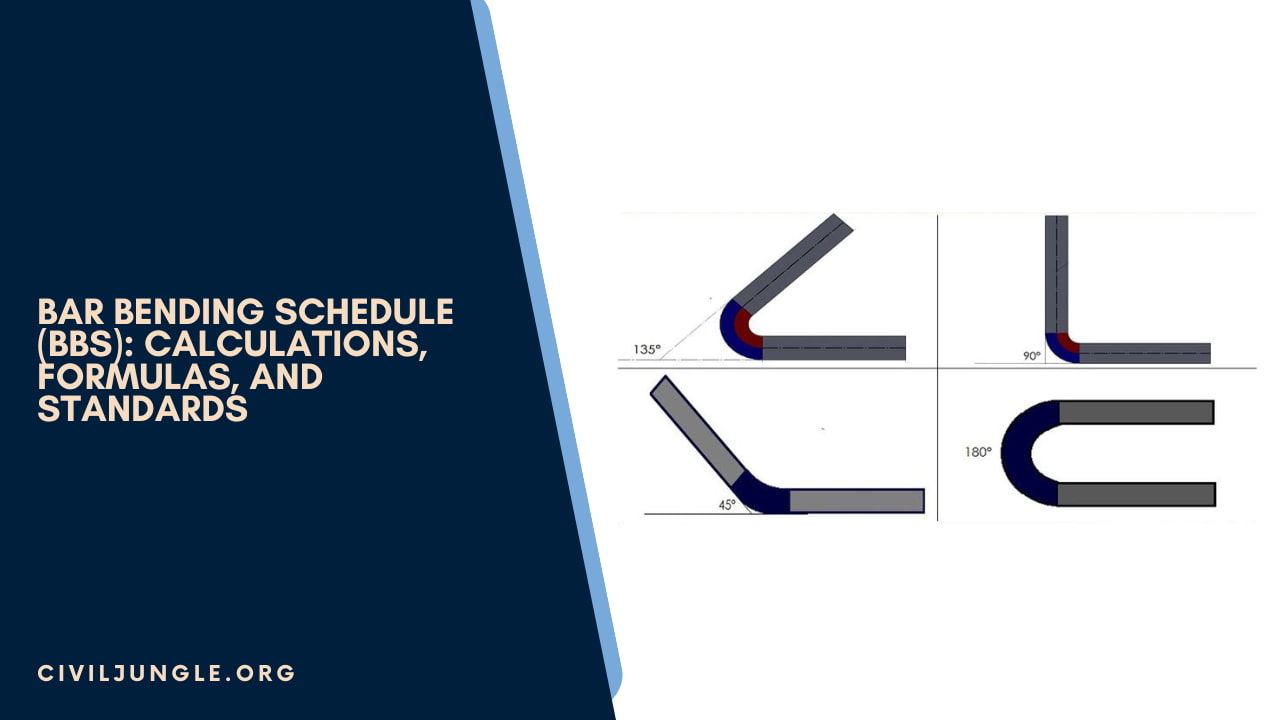

4. Bar Bending Schedule Formulas as below (As per IS 2502:1963, P-8, Table-III )

Measurement of Bending Dimensions of Bars for Reinforced Concrete ( As per IS 2502:1963, P-8, Table-III )

| Ref No. | Method of Measurement of Bending Dimensions | Approx Total Length of Bar (L) Measured Along Centre Line | Sketch and Dimensions to Be Given in Schedule | Approx Total Length of Bar (L) Measured Along Centre Line – Mild Steel | Approx Total Length of Bar (L) Measured Along Centre Line – Medium Tensile Steel |

Approx Total Length of Bar (L) Measured Along Centre Line – Cold-worked Steel |

| A |  |

2A + E + C +9d + B |  |

2A + E + C +9d + 6d

2A + E + C +15d |

2A + E + C +9d + 7d

2A + E + C +16d |

2A + E + C +9d + 8d

2A + E + C +17d |

| B |  |

4C + 24d |  |

4C + 24d | 4C + 24d | 4C + 24d |

| C |  |

4C + 20d |  |

4C + 20d | 4C + 20d | 4C + 20d |

| D |  |

2A + 3D + 22d |  |

2A + 3D + 22d | 2A + 3D + 22d | 2A + 3D + 22d |

| E |  |

2A + 3D + 22d |  |

2A + 3D + 22d | 2A + 3D + 22d | 2A + 3D + 22d |

| F |  |

Where P is not greater than D/5 N = Number of complete and fractional turns D = Internal dia P = Pitch of helix d = Size of barN π (D + d) + 8d |

– | N π (D + d) + 8d | N π (D + d) + 8d | N π (D + d) + 8d |

| G |  |

L + H |  |

L+H = L + 4d+ d+2kd = L + 4d +4d +d = L + 9d |

L+H = L + 4d+ d+2kd = L + (2 x 3)d +4d +d = L + 11d |

L+H = L + 4d+ d+2kd = L + (2 x 4 )d +4d +d = L + 13d |

| H |  |

L + 2H |  |

L+2H = L + 2 x (4d+ d+2kd) = L + ( 4d +4d +d) x2 = L + 18d |

L+2H = L + 2 x (4d+ d+2kd) = L + ((2 x 3)d +4d +d ) x 2 = L + 22d |

L+2H = L + 2 x (4d+ d+2kd) = L + ((2 x 4 )d +4d +d ) x 2 = L + 26d |

| I |  |

L + B |  |

L + B = L +4d + kd = L +4d + 2d = L +6d |

L + B = L +4d + kd = L +4d + 3d = L +7d |

L + B = L +4d + kd = L +4d + 4d = L +8d |

| J |  |

L + 2B |  |

L + 2B = L + 2x (4d + kd) = L +2 x (4d + 2d) = L +12d |

L + 2B = L + 2x (4d + kd) = L +2 x (4d + 3d) = L +14d |

L + 2B = L + 2x (4d + kd) = L +2 x (4d + 4d) = L +16d |

| K |  |

Where C is more than 3DA + C + E |

|

A + C + E | A + C + E | A + C + E |

| L |  |

If angle with horizontal is 45o or less, and R is 12d or less

A + C + E + 2H |

|

A + C + E + 18d or L + 18d + C – √ ( C2 – D2 ) |

A + C + E + 22d or L + 22d + C – √ ( C2 – D2 ) |

A + C + E + 26d or L + 26d + C – √ ( C2 – D2 ) |

| M | If angle with horizontal is 45o or less, and R is 12d or less

A + C1 + C2 + E + F +2H |

|

A + C1 + C2 + E + F +18d or L +C1 + C2 + 18d – √ ( C12 – D12 ) – √ ( C22 – D22 ) |

A + C1 + C2 + E + F +22d or L +C1 + C2 + 22d – √ ( C12 – D12 ) – √ ( C22 – D22 ) |

A + C1 + C2 + E + F +26d or L +C1 + C2 + 26d – √ ( C12 – D12 ) – √ ( C22 – D22 ) |

|

| N |  |

A + E – 0.5 R – d |  |

A + E – 0.5 R – d | A + E – 0.5 R – d | A + E – 0.5 R – d |

| O |  |

A + E – 0.5 R – d + 2B |  |

A + E – 0.5 R – d + 12d | A + E – 0.5 R – d + 14d | A + E – 0.5 R – d + 16d |

| P |  |

A + E – 0.5 R – d + 2H |  |

A + E – 0.5 R – d + 18d | A + E – 0.5 R – d + 22d | A + E – 0.5 R – d + 26d |

| Q |  |

A + E + 1.5 D + 2H |  |

A + E + 1.5 D + 18d | A + E + 1.5 D + 22d | A + E + 1.5 D + 26d |

| R |  |

If angle with horizontal is 45o or less A + E |

|

A + E | A + E | A + E |

| S |  |

If angle with horizontal is 45o or less R is 12d or less

A + E + 2H If the angle is greater than 45o and R exceeds 12d, L to be calculated |

|

A + E + 18d | A + E + 22d | A + E + 26d |

| T |  |

If angle with horizontal is 45o or less

A + B + C + H -2(R + d) If the angle is greater than 45o and R exceeds 12d, L to be calculated |

|

A + B + C + 9d -2(R + d) | A + B + C + 11d -2(R + d) | A + B + C + 13d -2(R + d) |

| U |  |

L + 2H |  |

L + 18d | L + 22d | L + 26d |

| V |  |

A + E + 2S + 2H + d |  |

A + E + 2S + 18d + d | A + E + 2S + 22d + d | A + E + 2S + 26d + d |

| W |  |

A + E + 3S + 2d + B +H |  |

A + E + 3S + 2d + 6d + 9d

A + E + 3S + 17d |

A + E + 3S + 2d + 7d + 11d

A + E + 3S + 20d |

A + E + 3S + 2d + 8d + 13d

A + E + 3S + 23d |

| X |  |

A + E + C + 2H – √ ( C2 – D2 ) -D |  |

A + E + C + 18d – √ ( C2 – D2 ) -D | A + E + C + 22d – √ ( C2 – D2 ) -D | A + E + C + 26d – √ ( C2 – D2 ) -D |

| Y |  |

E + 2(A – D + C + H) |  |

E + 2(A – D + C + 9d) | E + 2(A – D + C + 11d) | E + 2(A – D + C + 13d) |

| Z |  |

L + 2C + 2H |  |

L + 2C + 18d | L + 2C + 22d | L + 2C + 26d |

| AA |  |

2C + 2E1 + L + 2H |  |

2C + 2E1 + L + 18d | 2C + 2E1 + L + 22d | 2C + 2E1 + L + 26d |

| AB |  |

2 (A + E) + 24d |  |

2 (A + E) + 24d | 2 (A + E) + 24d | 2 (A + E) + 24d |

| AC |  |

2 (A + E) + 20d |  |

2 (A + E) + 20d | 2 (A + E) + 20d | 2 (A + E) + 20d |

| AD |  |

2A + E + 28d |  |

2A + E + 28d | 2A + E + 28d | 2A + E + 28d |

| AE |  |

2A + E + C +12d + B |  |

2A + E + C +12d + 6d

2A + E + C +18d |

2A + E + C +12d + 7d

2A + E + C +19d |

2A + E + C +12d + 8d

2A + E + C +20d |

| AF |  |

L | Straight | L | L | L |

Frequently Asked Questions (FAQs) About Bar Bending Schedule (BBS)

What Is a Bar Bending Schedule (Bbs)?

A Bar Bending Schedule (BBS) is a comprehensive list that specifies the details of reinforcement bars used in a construction project. It includes information such as the size, number, shape, and length of the bars, ensuring accurate calculation and placement of steel reinforcement.

Why Is Bbs Important in Construction?

BBS is crucial because it helps in the precise calculation of the quantity of steel required, reduces wastage, ensures accurate cutting and bending, facilitates easy handling of steel, and enhances the overall quality and efficiency of the construction project.

How Is the Weight of Steel Bars Calculated in Bbs?

The weight of steel bars is calculated using the formula: Weight of Steel=D2162.27\text{Weight of Steel} = \frac{D^2}{162.27} where DD is the diameter of the bar in millimeters. This formula provides the weight in kilograms per meter length of the steel bar.

What Are the Key Components of a Bar Bending Schedule?

Key components of a BBS include:

- Location of the bar

- Mark designation

- Size and type of bar

- Number of bars per set

- Number of sets

- Total number of bars

- Length of each bar

- Shape of the bar with dimensions

What Standards Are Followed for Preparing a Bar Bending Schedule?

The preparation of BBS follows specific standards such as IS:2502-1963, which outlines the rules and formulas for calculating the length and shape of reinforcement bars.

How Are Bends and Hooks in Bars Accounted for in Bbs?

Bends and hooks are accounted for by using allowances specified in standards like IS:2502-1963. For example, hook allowance (H) and bend allowance (B) are calculated based on the diameter of the bar and specific formulas provided in the standard.

Can Bbs Be Prepared Manually, or Is Software Required?

While BBS can be prepared manually, it is often more efficient and accurate to use computer software. Software can automate the calculations, reduce errors, and generate detailed schedules quickly.

What Is the Significance of the ‘Shape’ Column in Bbs?

The ‘Shape’ column in BBS indicates the bending shape of each bar, which is crucial for proper placement and fitting during construction. It ensures that the bars are bent and cut according to the design specifications.

How Do You Calculate the Total Weight of Steel Required Using Bbs?

The total weight of steel is calculated by summing up the weights of all individual bars listed in the BBS. Each bar’s weight is calculated based on its length and diameter using the weight calculation formula.

What Are Some Common Challenges in Preparing a Bar Bending Schedule?

Common challenges include ensuring accuracy in measurements and calculations, adhering to standard codes, managing variations in bar shapes and sizes, and coordinating with the construction team to align the BBS with the actual site conditions.