What Is a Dowel Bar?

A dowel bar is a small circle, and a flat steel rod applies to help a technical joint among slabs except confining parallel connection motion. These bars will mostly use to attach surface cement pavement to contain the extra pressure and burden of changing vehicles.

- What Is Rebar Size and Rebar Diameters

- What Is Development length | What Is Development Length of Bars

- Bar Bending Schedule Formulas As Per IS:2502-1963 | Unit Weight of Steel Bars

- How to Calculate Staircase Qty | Concrete & Bar Bending Schedule (BBS) | Staircase Reinforcement Details

- Steel Bar Calculation | Steel Bar Calculator | Reinforcement Weight | Reinforcement Weight Calculator | Rebar Weight Calculator

What Is the Function of the Dowel Bar?

It shifts the burden from one to another slab; two progressive slabs shift jointly and decrease shock storing growth by the slabs by their self-motion. To decrease junction blaming and edge broker. To develop the activity of pavement connection.

The measure dowel bars will be the base of a walkway, 18” in length, 1.25 to 1.5” in breadth, and an area of 12”. To save the bars from corrosion, they are also pure steel.

Purpose of Dowel Bar

The purpose of the dowel bar in follows:

- The purpose of the dowel bar is to the earlier activity of connections.

- Dowel bars will keep shifting the burden over the concrete connection.

- It will use to reduce edge breaking.

- Dowel bars will get for the goal of reducing the connection problem.

- It will get the sense of moving the burden from one slab to another slab.

- Best Concrete Mix for Driveway Repair

- All About Green Concrete | What Is Environmentally Friendly Concrete

- All About Transportation of Concrete | What Is Transportation of Concrete | Methods for Transportation of Concrete

- Concrete Batching | Concrete Batching Plant | Types of Batching of Concrete | Various Factors Affecting the Choice of Batching System

- All About Concrete Core Test | What Is the Concrete Core Test | Concrete Core Test Procedure | What Are Capping and Its Role in the Result

What Is the Use of a Dowel Bar?

Here, the list of used of dowle bar are as follows.

- Decrease the diversion and pressures.

- Improve the primary walkway path.

- Improve burden containing the volume of the slab.

- Dowel bar can apply to RCC slab and pillars.

Advantages of Dowel Bar

Here, the pros of dowel bars are as follows.

- They divert the split of the construction because of the necessary parallel motion.

- Dowel bars develop the activity of construction connection.

- They have applied to improve the burden volume of the slab.

- Pure dowel improves the introductory price of the construction but decreases the durability.

- Dowel bar will apply to spread the construction, and a sharp piercing will need to put the steel to add the form.

- Divert, and pressure can decrease by dowel bars.

- They can even improve the basic shape of organs life.

- M30 Grade of Concrete Mix Design Procedure with OPC 53 Cement

- What Is Cover in Concrete | Clear Cover in Beams, Slab, Column, Footing

- What Is Slab Beam / Hidden Beam / Concealed Beam | Advantage and Disadvantage

- What Is Rebar | Why use Reinforcement in Concrete | Types of Steel Reinforcement Bars

- What Is Bar Bending Schedule | Preparation as Per Bs 4466 | Tolerances as Per Bs 4466

Disadvantages of Dowel Bar

Here, the cons of dowel bars are as follows.

- Difficult to design.

- Badly compact concrete surrounds dowel bars.

What Is the Dowel Bar in the Staircase?

Dowel bar conducts a specific pressure to separate the bar. It will be essential to shift this pressure around pavement during a particular height in the bar.

The anchorage value is four times the length of 45 degrees each bar pacified to the highest of 16times the length of bars.

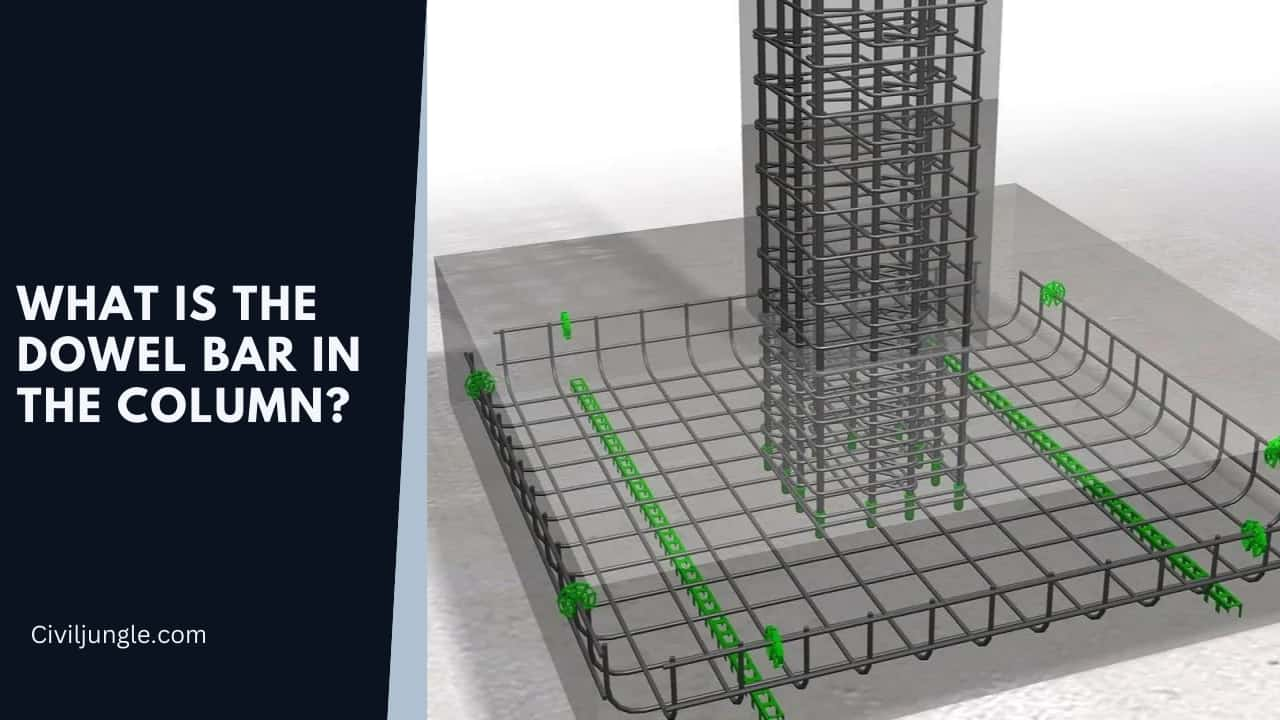

What Is the Dowel Bar in the Column?

Dowel bar will offer in-stay pavements to move the burden from columns to the surface. They are essential while the pavement conduct is insufficient to move the draft from the column to the surface. The dowel will spread into the queue at length similar to the improved column distance.

- How to Reduce Construction Cost (Tips)

- Top 10 Construction Companies in UAE

- House Construction Cost Calculator Excel Sheet

- How to Building Construction Process Step by Step

- House Construction Cost Calculator | How to Work With House Construction Cost Calculator. | What Is Construction Rate

- 20 Vastu Tips Before House Construction | Vastu Tips for Different Locations of House | Scientific Facts of Vastu Location of Rooms

What Is a Dowel Bar in Construction?

Dowels are concrete bars fixed in the construction connection of dowel concrete to support the burden of moving among unique slabs.

Dowel bars are small concrete bars that proceed with technical joints among blocking parallel connect motion. Generally, they will fix at the crosswise connection and prefer burden shift from one to other slabs.

What Are Dowel Bars Used For?

Dowel bars are short steel bars that are installed in concrete slabs to provide a mechanical connection that doesn’t restrict horizontal joint movement. They are designed to reduce joint deflection and stress in the approach and leave slab by increasing load transfer efficiency.

What Is Dowel Bar and Tie Bar?

Tie bars are not load transferring device. For instance, tie bars are used in longitudinal joints in concrete pavement. Dowel bars are smooth round bars which mainly serve as load transfer device across concrete joints. They are placed across transverse joints of concrete pavement to allow movement to take place.

What Is Dowel Bar in Wall?

Dowel bars are short steel bars that provide a mechanical connection between slabs without restricting horizontal joint movement. They increase load transfer efficiency by allowing the leave slab to assume some of the load before the load is actually over it.

How Are Dowel Bars Placed?

Dowel bars are typically placed at the mid-depth of the slab and should be parallel to the pavement surface and parallel to the direction of travel. The center of the dowel bar should be below the joint.

Are Dowels Stronger Than Screws?

Dowel joinery is stronger than screw joinery. The increased glue surface caused by the glue deeply penetrating the wood gives the dowel more holding power. The clamp and dry method used in dowel construction ensures that the joint is sufficiently set before the next step in building the item is taken.

Why Is It Called a Dowel?

The word dowel is an old English word equivalent of “doule” which simply means a part of a wheel. It can also be traced its history in the Middle German language “dovel” which meant to plug.

Dowel Bars in Concrete Slab

Dowel bars are short steel bars that provide a mechanical connection between slabs without restricting horizontal joint movement. They increase load transfer efficiency by allowing the leave slab to assume some of the load before the load is actually over it.

What Is Dowel Bar in Slab?

Dowel bars are short steel bars that are installed in concrete slabs to provide a mechanical connection that doesn’t restrict horizontal joint movement. They are designed to reduce joint deflection and stress in the approach and leave slab by increasing load transfer efficiency.

Why Dowel Bars Are Used in Concrete Pavement?

The primary advantage of dowel bars is to transfer load without restricting horizontal joint movements due to temperature and moisture expansion and contraction in the concrete slabs. Also, dowel bars play a role to maintain the vertical and horizontal alignment of slabs.

How Do You Place a Dowel in Concrete?

Dowel bars are typically placed at the mid-depth of the slab and should be parallel to the pavement surface and parallel to the direction of travel. The center of the dowel bar should be below the joint. If dowel placement deviates from the desired position, it is said to be misaligned.

What Do Concrete Dowels Do?

Dowels are placed in transversal contraction or construction joints of concrete pavements and help to transfer loading between individual slabs. Dowels allow horizontal movement of slabs during contraction in the time period after laying the concrete pavement and at temperature changes.

Where Are Dowel Bars Placed?

The dowel bars embedded in concrete pavements transfer the load across the construction joints. When aligned properly, they help reduce faulting and improve the pavement’s performance.

Do You Need Dowels in Concrete?

If the design lane (most heavily trafficked lane) of the roadway has less than 80 trucks per day, dowels are probably not needed. However, if the design lane has more than 120 trucks per day, dowels are most likely needed.

How Deep Should Concrete Dowels Be?

Current recommended practice for doweled joints is for dowel diameters to be one-eighth of slab thickness, dowel spacing to be 12 in., and dowel length to be 18 in. Dowel bars require care in placement to minimize detrimental effects of misalignment.

How Long Is a Rebar Dowel?

12″, 18″, 24″ and 48″ dowel bars both smooth and standard are always in stock.

How Do You Measure the Length of a Dowel?

Twice this length is a common rule of thumb for determining dowel length. For example, if your shortest member is 1” thick and you know your safest drilling depth is 3/4”, then a 1-1/2” dowel should be used. A 1-1/2” length equates to two times the 3/4” thickness. The longer the dowel, the greater the holding strength.

Do You Need Dowels in Concrete?

If the design lane (most heavily trafficked lane) of the roadway has less than 80 trucks per day, dowels are probably not needed. However, if the design lane has more than 120 trucks per day, dowels are most likely needed.

Can Rebar Be Used as Dowels?

Rebar dowels can be used for forming or as connector ties in concrete projects. Rebar dowels can be used for forming or as connector ties in concrete projects.

How Big Should a Dowel Be?

Ideally, the diameter of the dowel should be approximately 1/3 – and never more than 1/2 – of the thickness of the wood being joined. For example, if your product is 1” thick, you should be considering a dowel pin 3/8” in diameter. If your product is 1-1/4” thick, a 7/16” diameter would be more suitable.

Should Dowel Be Bigger Than Hole?

The holes are typically the same size as the dowel. Dowels are usually compressed wood, compressed in such a way that it leave lengthwise grooves in the sides all around. These grooves serve as a relief for the glue when the dowels are inserted, both dowel and hole should be coated.

How Deep Should a Dowel Go?

The holes to accommodate the dowels should each be drilled about 1/16 of an inch deeper than 1/2 of the length of the dowel section being used. Dowels 1 1/2-inches long are commonly used, so in this case, you would drill each of your doweling holes to 13/16 of an inch in length.

What Is the Recommended Dowel Length in Meters Used for Concrete Pavement Joints?

The recent recommended total length of dowel is 457 mm (18 in) to achieve good pavement joint performance. Load transfer versus dowel embedment. Effect of dowel embedment and diameter on dowel looseness after 600,000 repetitions. Dowel bar misalignment does not necessarily result in slab distresses.

How Long Is a Standard Dowel Rod?

Length: 3, 4, 5, and 6 foot are commonly stocked. Longer lengths, up to 16′ available on special order. Species: Birch, Oak, Maple, Poplar are the most readily available.

Dowel Bars in Column

Dowels are commonly used as interface reinforcement between columns or walls and footings. The dowels are set in the footing prior to casting the footing concrete and are subsequently spliced to the longitudinal bars in the column or wall.

Where Dowel Bars Are Provided?

The dowel bars are provided in the direction of the traffic (longitudinal). Half length of this bar is bonded in one cement concrete slab and the remaining portion is embedded in adjacent slab, but is kept free for the movement during expansion and contraction of the slab.

Dowel Size and Spacing

| Dowel size and spacing. | ||||

| Empty Cell | Slab thickness (cm) | Dowel diameter (cm) | Minimum length (cm) | Maximum spacing (cm) |

|

JTG D40–2002

|

22 | 2.8 | 40 | 30 |

| 24 | 3 | 40 | 30 | |

| 26 | 3.2 | 45 | 30 | |

| 28 | 3.5 | 45 | 30 | |

| 30 | 3.8 | 50 | 30 | |

|

JTJ 012–94

|

<20 | 2 | 40 | 30 |

| 21–25 | 2.5 | 45 | 30 | |

| 26–30 | 3 | 50 | 30 | |

Dowel Size Recommended by Portland Cement Association

| Slab thickness (cm) | Dowel diameter (cm) | Dowel embedment length (cm) |

Dowel length (cm)

|

| 12.5 | 1.6 | 12.5 | 30 |

| 15 | 1.9 | 15 | 35 |

| 20 | 2.2 | 15 | 35 |

| 20 | 2.5 | 15 | 35 |

| 22.5 | 2.8 | 17.5 | 40 |

| 25 | 3.1 | 18.8 | 45 |

| 27.5 | 3.5 | 20 | 45 |

| 30 | 3.8 | 22.5 | 50 |

Minimum Length of Dowel Bars

|

Diameter (mm)

|

Dowel length (mm)

|

|

Minimum dowel length

|

|

| 22 | 400 |

| 24 | 400 |

| 26 | 400 |

| 28 | 400 |

| 30 | 400 |

| 32 | 450 |

| 35 | 450 |

| 38 | 500 |

Dowel Bars Specification

Dowel bars are typically 32 to 38 mm (1.25 to 1.5 inches) in diameter, 460 mm (18 inches) long and spaced 305 mm (12 inches) apart.

Like this post? Share it with your friends!

Suggested Read –

- All About Wood | Types of Wood | What Is Wood | Advantages of Wood

- All About Rugs | What Is Rugs | Types of Rugs | Different Types of Rugs for Horses

- What Is Wood | Significance of Utilizing Wood in Construction | Main Types of Woods

- All About Water Treatment Process | Water Treatment Process Steps | Types of Drinking Water Treatment Process

- All About Mattresses | Types of Mattresses |Types of Mattresses Pros and Cons |Which Type of Mattress Is Best for the Body

- All About Kitchen Cabinets | Types of Kitchen Cabinets | Types of Kitchen Cabinets Partial Overlay | Types of Kitchen Cabinets Materials | Types of Storage Cabinets