What to Do If the Concrete Cube Fails After 28 Days?

Such a condition appears considerable duration on the construction point. This composition describes what to accomplish and not do during comparable circumstances on the construction pinpoint.

So, What To Do If Concrete Cube Falls after 24 days? There are many record and recovery choices if the concrete cell falls in the Test.

Cube Test of Concrete

The Concrete cube test collections feature all the qualities and strengths of Concrete. From the outcome of this cube test, we can evaluate whether Concreting has stood accomplished appropriately or not.

The strength of Concrete for functional construction contradicts the grade of Concrete, from 15 MPa (2200 psi) to 30 MPa (4400 psi), and is equipped in retail and dispersed structures.

Compressive Strength Definition

“Compressive strength is the capacity of material (Concrete) or structure to bear the loads on its surface without any damage or variation. ”

Compressive Strength Test of Concrete Cubes

For Inspecting the compressive strength of Concrete, two categories of typical models are utilized.

Cube model dimensions 15 cm X 15 cm X 15 cm or 10 cm X 10 cm x 10 cm counting upon the dimensions of capacity are utilized. Usually, we utilize molds of 15 cm x 15 cm x 15 cm.

During Concreting work, the random concrete sample is streamed into the earth and solidified suitably to avoid openings. Concrete from these molds is released in the coming day, and test selections stand positioned in water for healing.

For the Cube test, it’s elemental to complete the top face of this sample slippery. That should do by setting cement paste and extending efficiently on the complete measurement of the sample.

Testing of Cube Samples

Concrete cube samples area experimented on compaction testing machine behind seven days curing or 28 days curing. The processing load is gradational at the speed of 140 kg/ cm2 per nanosecond till the Samples fall.

The compressive strength of the concrete cube is the burden concerned at the point of destruction to the cross-section measurement of the front on which the load is applied.

Concrete Cube Testing

The compressive strength of Concrete is computed by the following equation (15 cm x 15 cm x 15 cm) Compressive strength = load at the collapse in Machine (N)/ C/ S Area of Cube (mm ²)

Strength of Concrete at Various Ages

It’s a comprehended actuality that concrete strength grows with generation. Downcast is the strength of Concrete at further terms resembled the strength at 28 days after throwing.

- Concrete cube test outcomes -28 days

- Concrete cube test outcomes -7 days as per is law

- Three days of concrete cube strength

|

Sr.no. |

Age of Concrete |

Compressive Strength Gain (%) |

| 1 | Three days | 30 % |

| 2 | Seven days | 67.5 % (70% for safety) |

| 3 | 14 days | 90 % |

| 4 | 28 days | 99 % (70% for safety) |

Concrete Strength of Cube at 7 and 28 Days Test

Table of the Grade of Concrete

|

Grade of Concrete |

Minimum Compressive Strength N/mm2 at Three Days (30%) | Minimum Compressive Strength (N/mm2) at Seven Daytimes (70%) |

Specified Characteristic Compressive Strength (N/mm2) at 28 Daytimes(100%) |

| M – 15 | 4.5 | 10 | 15 |

| M – 20 | 3 | 13.5 | 20 |

| M – 25 | 7.5 | 17.5 | 25 |

| M – 30 | 9 | 21 | 30 |

| M – 35 | 10.5 | 21 | 35 |

What to Do If Cube Test Fails in Test After 28 Days?

The initial reaction is” Prevention is more promising than cure”-The collapse of the Cube test relies upon the multicolor element; the way it has experimented is also necessary. The portion for the cube is also veritably significant.

By reversing a reasonable reason for failure, we may avoid further prospects of replication. concrete cube falls in Test after 28 daytimes.

When we’re accomplishing concreting on point and assemblage Samples for the Test, there are four probable combinations after the Concrete cube fails, as described downward.

- It may be Concrete is firm; the cube is also firm.

- It may be concrete is vulnerable; the cube is also vulnerable.

- It may be Concrete is firm, but the cube is vulnerable.

- It may be concrete is weak, but the cube is firm.

Typically, we consolidate on the first two opportunities while assaying cube test consequences; the third and fourth possibilities are normally disregarded.

The 3rd option doesn’t harm the procedure. But intention four, well, it is more convincing to be optimistic in identical circumstances.

While you get information demonstrating that the 28th- day cube tests are forgotten, recognize that its entity is profound. This test development on the 28th day can not regale, just like in the matter of the 7th- day test failure.

We must acquire 99 strength on the 28th- day cube test impact, and trials are considered the deciding standard for endorsement of the Concrete.

Before considering that our 28th- day cube test is forgotten or departed and going profound into our hand of cube collapse, let us dashingly notice how the cell developments are typically analyzed as per IS the law.

There are two requirements are to be satisfied for receiving a concrete after cube test as per IS 456: 2000

For Concrete of Grade M- 20 and Over,

The moderate strength of a collection of four consecutive test effects shouldn’t be lower than the lesser of fck (20) 4 N/mm2 or fck0.825 σ, where σ is the standard deviation designated Separate cube strength shouldn’t be more inferior than fck – 4 N/mm2.

For Example:-

If the 28th days concrete cube test consequences fall, examine if the outcome of all seven days’ cubes is identical. If one gives the superior benchmarks, you’re sure that the concrete combination is OK.

Now the Inquiry of Artistry

Certainly, if one of the cubes is OK, stay for a 28 Day result. If 28 days consequence also falls furthermore, there’s an opportunity that cubes aren’t sufficed duly or weren’t mended appropriately in the first seven days.

But slab concrete may be OK. Run for the Hammer test. If the hammer test corresponds to the fallen cube consequence, go for the core knife and test it to get the genuine strength of the applied Concrete.

Take this core knife consequence to the consultant, and he’ll determine whether he can retain the Concrete with rectification like grouting and all.

Nevertheless, also whether he can find ways to maintain the slab, If not. Nonetheless, also he has to get the slab recast, If not.

We must consider the pursuit before the point mastermind determines to discard Concrete.

- Whether cubes sufficed by a trained executive?

- Whether the strength inferior as per the right formula?

- If so, whether they fulfill the originator with corrective styles as suggested and NDT test effects documented from labs?

- Still doubtful go for lading test?

I’ve tolerated horrible results from many labs in multiple cases, but the point mastermind should hold his conclusion about the Concrete’s location falling and taking traps.

The contractor shall always be pleased if decreased rates are delivered for a parallel workshop but always document any losses that require your pre-action reports. Only a point individual can determine to scrap Concrete.

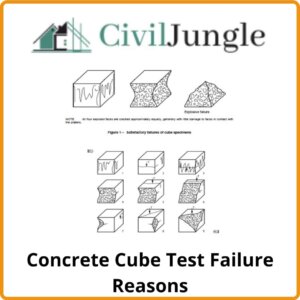

Concrete Cube Test Failure Reasons

The ensuing are the immediate concrete cube trial failure explanations,

- Wrong Mix Poured The concrete blend scheduled isn’t the consented combination strategy for that individual strength.

- Wrong Mix Design There’s an error in the concrete combination design. It isn’t duly organized, and strength isn’t duly estimated.

- Improper Sample Collection Sometimes concrete model for the cube test isn’t contained by a professed worker, or a specialized person may not correspond to it on a pinpoint. So, there may be prospects that the stockpiled concrete instance isn’t truly describing the fresh Concrete delivered at the point. Indecent Cube Trial.

- The concrete cure must be a privilege per the pedagogy given in IS 516.

- Several compressive offenses might impact the compressive strength of concrete cube during cube casting, parallel as,

- Indecorous alignment of cube mold is acting in deformed cube shape,

- Indecorous/ shy tamping Improper tamping results in voids conformation in the cube model

- Shy Curing of the Cube Samples

- The curing of the concrete cube can be as per the instruction delivered in IS 516.

- Once the concrete cube is organized, the cubes must protect with wet gunny bags for the most undersized 24 hrs from when water is preferably counted to the Concrete.

- Furthermore, after clearing the concrete cube from the molds and maintaining it under neat water until the test time. Completely infallible, the curing temperature is between 24 ˚C to 26 ˚C.

- Experimenting Wrong Samples Duly, recognize the cube medication marking on the cube—periodically wrong cell sample test.

- During Testing, this includes improper placing of molds over the CTM, pulling the face, ditching the cube, rate of cargo procedure, etc.

- Crimes With the Testing Apparatus This may contain crimes with the reading exhibition, lading or hydraulic techniques, or a homemade blunder in homework and diagnosing the expressed value.

- Unauthorized Water- Cement Rate Correction of the Mix Periodically, completing concrete fluently friendly labor counts repetitious water without conferring a specialized person.

- The difference in Quality of Accoutrements Occasionally, the element of concrete accouterments utilized to possess the concrete blend on-point may discuss from those utilized while formulating the course blend.

- Batching Factory Error There may be the possibility of batching factory error wrong accouterments volume added in the blend, due to any mechanical/ software blunder, which went unrecognized.

What to Do If We Don’t Want to Strike the Concrete Member?

We can strengthen the helpless members/ members to receive the firstly developed load. This system modification is substantially determined by the helpless associates and hence is easy to preserve the trail of the methodology.

Still, the future of this system relies on other elements again. There are considerable changes to sustain a weak concrete member if a concrete cube fails in the Test

1 Providing Steel Casing

It furnishes steel comprising almost the structure, specifically columns, to assemble it as a combination member to enhance its structural interpretation.

2. Providing Steel Stiffeners

They are delivering Steel stiffeners on the flanks of the associate to extend its cargo-carrying ability. The sword stiffeners may escape or relate the library paste to the substantial member.

3. Providing Fiber Reinforced Polymer (Frp) Distance Relating

Reinforced Polymer (FRP) distance predominantly with glass fiber – GFRP or carbon fiber and more inferior surface are encased about the countenance of the concrete member and connected with library paste adhesive.

So, Concrete’s structural gesture is enhanced. Concrete Form by Carbon Fiber Reinforced Polymer (FRP) distance

4. Sprayed Concrete/ Shotcreting

Sprayed concrete/ shotcreting can be accomplished by drilling underpinning around the perimeter of the member, and Shotcreting is done on the face of the constituent to raise its sampling to alter the structural version.

5. Attaching Pre-Tensioned Lines to the Concrete Members

Fastening pre–slackened lines to the concrete member method isn’t so normally utilized. In this system, we develop there-stressed associates into being associates.

6. Concrete Jacketing

The concrete Jacketing troubles encompassing the structural branch at any flanks with talent thoroughly placed corroborated Concrete.

In this system, mounting is welded to the being underpinning to accomplish good cling of the jacket to the being element. Concrete Jacketing boosts the cross-section area of the associate, thereby perfecting its structural interpretation.

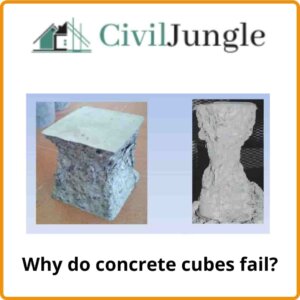

Why do Concrete Cubes Fail?

The element answerable for the failure of Concrete is the poor outcome of concrete compressive strength within the Concrete, which is trustworthy for the consequence of insufficient strength.

Factors equivalent as improper tamping, improper alignment of the earth, remains of the weak area due to shy packing, misshapen cube shape, and differentia of accouterments utilized are the cause of a comparable defeat.

Why Do They Test Concrete for 28 Days?

The Strength concrete formulated in 1, 3, 7, 14, and 28 days are well comprehended by the rehearsal pantomimist, as these are regarded the standard importance as per principles. Likewise, concrete yields 99 of its total strength in 28 days, equal to 100. Hence, Concrete is tried for 28 days to attain factual developments.

What is the Strength of Concrete After 28 Days?

Concrete achieves a total of 99% of the Compressive Strength after 28 Days. Nonetheless, save for the rate of Compressive Strength of different grades of Concrete, the worth will vary from grade to grade.

For sample, Cube of grade M25 of size 15cm X 15cm X 15cm compressive strength of around 25N/mm2.

What Happens If a Concrete Cube Fails?

The first reaction is” Prevention is better than cure”- The collapse of the Cube test relies upon the colorful element; the way it has been tested is also necessary.

The slice for the cube is also veritably essential. The loss of development of a concrete cube is a severe problem. It would be best if you dissected why the cubes have failed.

Changing out a proper reason for failure may avoid further reoccurrences. concrete cube descends in Test behind 28 days.

When we’re accomplishing concreting on the significance and holding Samples for the Test, there are four potential multiplicities after the Concrete cube fails, as documented downward.

Sprayed Concrete / Shotcreting :

Sprayed concrete/shotcrete can be accomplished by drilling support around the periphery of the member, and short concreting is accomplished on the cover of the component to enhance its cross-section to modify the structural interpretation.

Attaching Pre-Tensioned Cables to the Concrete Members

Fastening pre-tensioned cables to the concrete component technique is not so commonly utilized. In this form, we affect the result of the pre-stressed associate on the existent member.

Concrete Jacketing

The concrete Jacketing concerns surrounding the structural member with skillfully placed reinforced Concrete at any or all flanks.

In this strategy, reinforcement is united with the current reinforcement to impart proper jacket sticking to the extant member. Concrete Jacketing raises the member’s cross-section area, enhancing its structural performance.

Conclusion of Concrete Cube Fails After 28 Days

From the overhead Answer, alternative six would appear to be the most leisurely one to overwhelm the Concrete tube Falling in the Test, but there exist several prerequisites to this process, like debris removal and the practical ordeal of destruction without harming other components.

There are again the hazards to the safeness of the workers, suitable predicament in shuttering and casting new members in the original function, quality management, etc., are a few limitations to note with this prospect.

What Occurs If a Concrete Cube Fails?

The first response is ” Prevention is more reasonable than cure”- The loss of the Cube test leans upon the various factors. Even the way it has been tried is also vital. The preference for the cube is also very meaningful.

The loss of influence of a concrete cube is a profound concern. It would be sufficient if you examined why the cubes have fallen.

We may avoid further reoccurrences by finding a reasonable defense for dealing with a concrete cube. The concrete cube tumbles in Test after 28 days

When we accomplish concreting on-site and handling Instances for the Test, there are four probable assortments after the Concrete cube falls in the Test, as remarked downward.

Conclusion of Concrete Cube Fails

From the overhead Answer, alternative six would appear to be the most leisurely one to overwhelm the Concrete tube Falling in the Test, but there exist several prerequisites to this process, like debris removal and the practical ordeal of destruction without harming other components.

There are again the hazards to the safeness of the workers, suitable predicament in shuttering and casting new members in the original function, quality management, etc., are a few limitations to note with this prospect.

FAQ: Concrete Cube Test Failures

What Is a Concrete Cube Test?

The concrete cube test assesses the compressive strength of concrete by testing samples (cubes) that have been cured for a specified period. The results help determine if the concrete meets the required strength standards for construction.

Why Do Concrete Cubes Fail the 28-Day Test?

Concrete cubes may fail the 28-day test due to several factors, including incorrect mix proportions, improper curing, defects in the cube molds, errors in sampling, or issues with testing equipment.

What Should Be Done If a Concrete Cube Fails After 28 Days?

If a concrete cube fails the test, first determine if the failure was due to issues with the testing process or the concrete itself. Conduct further investigations, such as reviewing the mix design, sampling methods, and curing practices. Consider non-destructive testing methods or core sampling to assess the actual strength of the concrete in the structure. If necessary, consult a structural engineer for remediation strategies.

What Are Common Reasons for Concrete Cube Test Failure?

Common reasons include incorrect mix design, improper sample collection and curing, misalignment of molds, inadequate tamping, and errors in testing procedures. Issues with the testing apparatus or variations in material quality can also contribute to failures.

How Can the Failure of Concrete Cubes Be Prevented?

Prevent failure by ensuring accurate mix proportions, proper curing of samples, correct sampling procedures, and meticulous handling of cube molds. Regularly calibrate testing equipment and follow standardized testing protocols.

What Are the Options for Remediation If a Concrete Cube Fails?

Remediation options include strengthening the affected concrete member through techniques such as steel casing, steel stiffeners, fiber-reinforced polymer wrapping, sprayed concrete (shotcreting), or concrete jacketing. Consult a structural engineer to determine the most suitable method for the specific situation.

How Long Does Concrete Need to Cure Before Testing?

Concrete typically needs to cure for 28 days to achieve its full strength. However, interim tests can be conducted at 3, 7, and 14 days to monitor strength development.

What Is the Significance of the 28-Day Test Result?

The 28-day test result is crucial because concrete generally reaches about 99% of its compressive strength by this time. It is the standard period for evaluating concrete strength and ensuring it meets design requirements.

What Actions Should Be Taken If the Cube Test Results Are Inconsistent?

If test results are inconsistent, verify the testing procedures and equipment calibration. Re-examine the sample collection and curing methods. If necessary, perform additional tests and consult with a structural engineer to determine the structural integrity of the concrete.

Can a Concrete Member Be Used If the Cube Test Fails but Other Tests Show Acceptable Strength?

Yes, if other tests, such as non-destructive testing or core sampling, indicate that the concrete has acceptable strength, the member can potentially be used. However, it is important to address any potential issues identified and ensure that the concrete meets the required performance criteria.