Introduction of Bituminous Pavement

Bituminous Pavement, often referred to as bituminous road layers, consists of their surface with materials that are also called Asphalt.

Asphalt is also known as bitumen. Asphalt is a sticky dark viscous liquid obtained from natural deposits like crude petroleum.

Bituminous pavements are constructed in layers like base, binder, and face course. These layers are made from different accoutrements and provide different functions to the bituminous pavements.

The bituminous Pavement is a flexible structure. A flexible road structure is a combination of several layers, which serves to distribute the loads from the business (both dynamic and static) to the beginning layers in a position so that the layers can bear without failure.

The stress is maximum at the top face of the Pavement. This value of stress decreases with the depth from top to bottom. So, a criterion about strength and the frugality factor is decided grounded on the same conception.

In bituminous Pavement, the top material of the Pavement must be of lesser strength and the nether most subcaste used can be of lower strength bringing frugality in construction.

What is Bituminous Pavement?

Bituminous Pavement consists of their surface with materials which are also called Asphalt. Asphalt is also known as bitumen. Asphalt is a sticky dark viscous liquid obtained from natural deposits like crude petroleum.

Bituminous face treatment or chip seal is employed substantially on low-business roads.

Bituminous pavements offer high descent resistance and give a high discrepancy in colour between bituminous pavement and road labels, giving motorists better road visibility in any rainfall conditions.

In bituminous Pavement, bitumen cover the Pavement also covered with fine summations. Presently, rigid concrete pavements should be preferred over bituminous Pavement due to their high continuity and high strength.

In bituminous Pavement, bitumen cover the Pavement also covered with fine summations.

What is Bituminous Paving?

In a pavement structure, types of bituminous road paving fusions are used as a face or base layer, defining the bituminous road meaning.

Bituminous paving has to distribute stresses caused by lading and cover the underpinning footloose layers from water goods. Numerous factors affect the power of a bituminous paving admixture to satisfy these structural conditions.

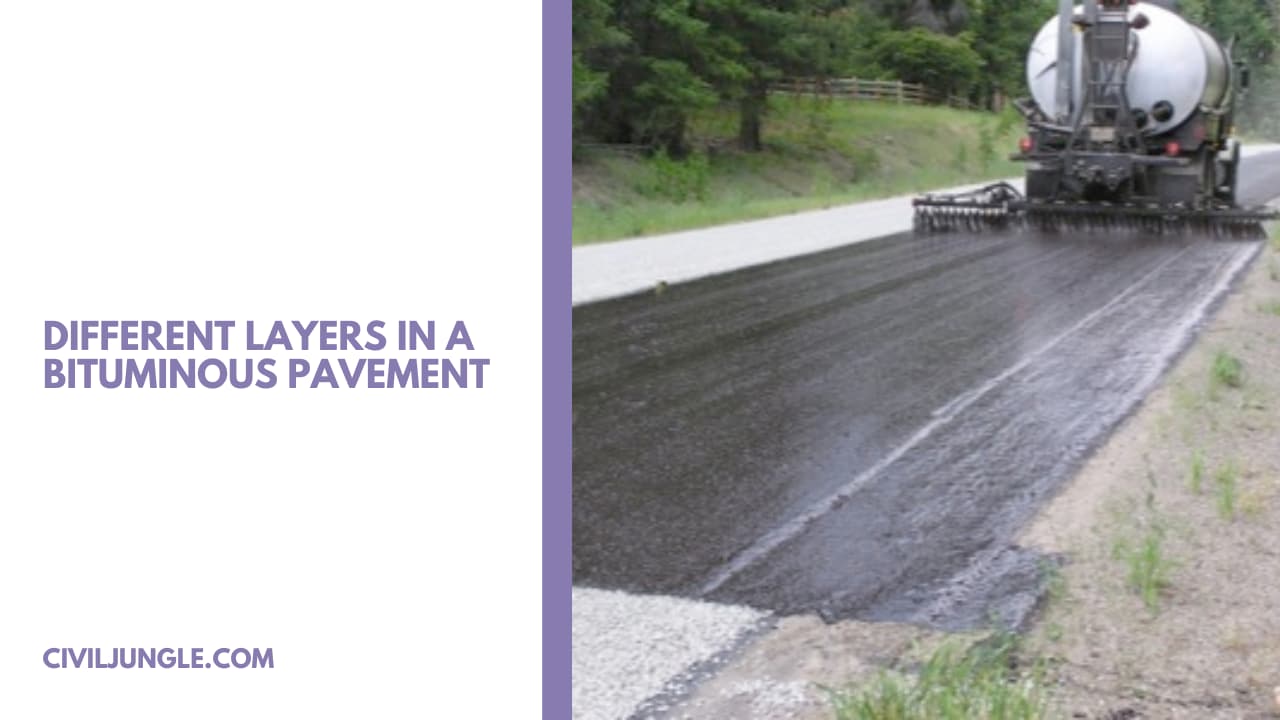

Different Layers in a Bituminous Pavement

Bituminous pavements, showcasing the layers of bituminous pavement, are constructed in different layers like a bituminous base course, bituminous binder course, and bituminous face course.

Bituminous concrete layers are made of different accoutrements and provide different functions to the bituminous pavements.

Different layers in a bituminous Pavement are as follows:

- Bituminous Base Course

- Bituminous Binder Course

- Bituminous Concrete Sub caste / surface course

1. Bituminous Base Course

Base course sub caste in a bituminous pavement consists of mineral summations like clay, monuments, and beach clicked together with bituminous accoutrements.

Bituminous base course sub caste is used as the foundation on which face course or binder is placed.

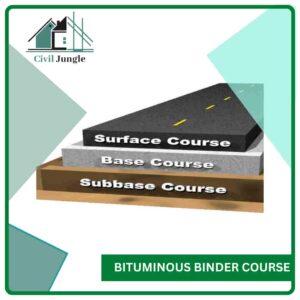

2. Bituminous Binder Course

The bituminous binder course layer is an intermediate layer between base course and surface layer. Bituminous binder course is that the first layer just in case of two-layer bituminous resurfacing.

A bituminous binder course is made of the bituminous aggregate mixture, also called a levelling course.

3. Bituminous Concrete Sub Caste/surface Course

Bituminous concrete sub caste is an admixture of summations that are continuously graded from maximum size to minimal sizes, which are generally lower than 25 mm to0.075 mm summations.

In bituminous concrete sub caste, sufficient bitumen is added to the blend so that the compacted concrete blend is effectively impervious. The bituminous concrete sub caste is respectable dissipative and elastic parcels.

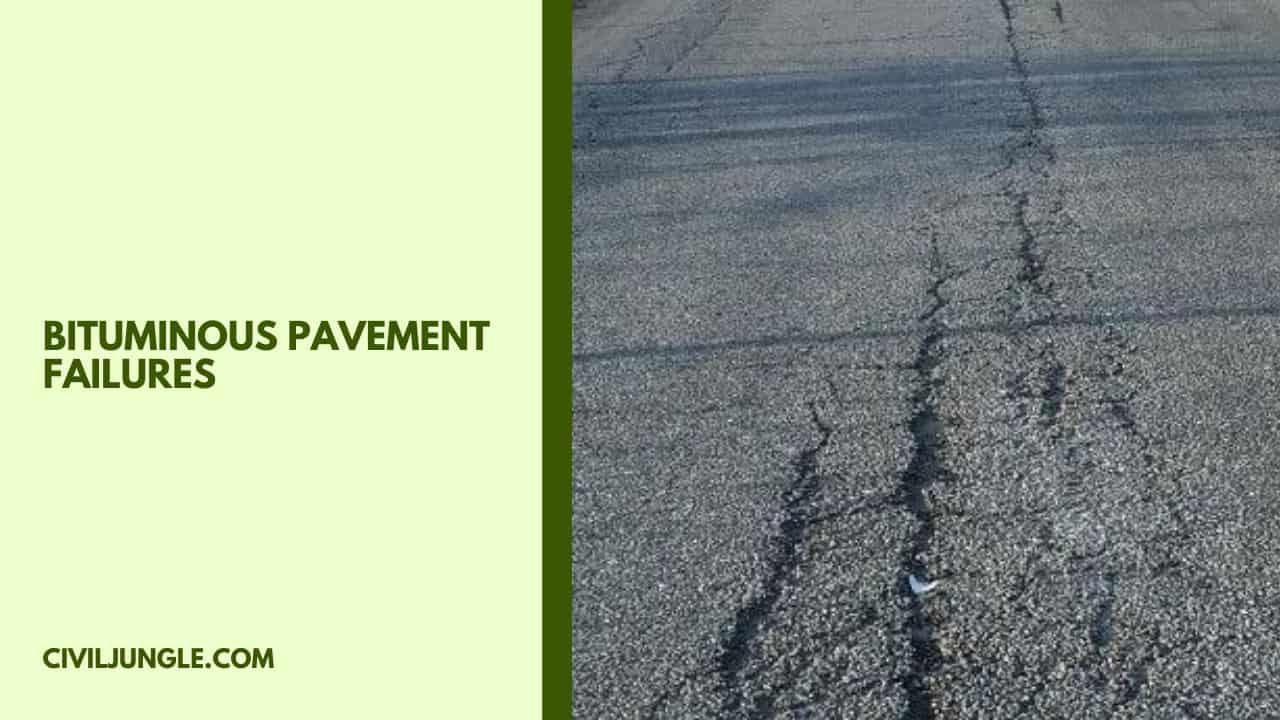

Bituminous Pavement Failures

There are different types of bituminous pavement failures. Determination of this failure and its reasons is necessary to grease correction in blend design and construction for the unborn systems.

- Functional Failures

- Structural Failures

- Functional Failure of Bituminous Pavement Structures

1.Functional Failures

The deterioration of the pavement face with time creates torture, which shows the functional failure.

The main reasons behind functional failure are raveling, which involves gravestone loss or through fretting or the reduction of face texture due to advanced bruise or polishing effect that would, in turn, drop the descent resistance shown by the road.

These types of torture are observed from the top down. The remedy for like problems is a face operation. It also includes crack sealing, seal coating, chip seals, skin-parching.

1.1 Bleeding

Redundant bituminous binder being on the pavement face causes bleeding. Bleeding causes a candescent, glass-suchlike, reflective face that may be tacky to the touch generally, plant in the wheel paths.

Bleeding is caused by lower air void content – no acceptable voids for the bitumen to access.

1.2 Block Cracking

Block cracking is also called thermal cracking. The cracking is passing in the form of blocks. These cracks are connected, making the Pavement divide into blockish pieces.

The size of each cube may vary from one bottom by one bottom to ten bottoms by ten bottoms.

Block cracking is an after effect of environmental exposure; hence it’s called thermal cracking. The temperature goods and ageing are the possible reasons.

1.4 Bumps and Sag

Pavement face that’s localized and small in the area that has experienced an upward relegation will be named bumps. These are caused due to the insecurity factor of Pavement. Several factors contribute to hitting conformation.

They can be caused due to buckling or the bulging of the concrete crossbeams. The sags are substantially caused due to the agreement or the relegation of the pavement face. Sags are small, abrupt and localized.

1.5 Edge Cracking

During the contraction process of the Pavement, the edges will start to yield, especially when there’s no kind of confinement like checks or edge walls.

The edges will yield with age, suffer oxidation and becomes brittle. The edge cracking is observed in the shape of ‘C’ formed along the road’s edges, parking lot or the roads.

1.6 Common Reflection Cracking

These cracks are observed in the flexible overlay over a rigid pavement. The rigid pavement joints are beginning to experience these cracks.

This type of failure occurs when a bituminous face course is laid over cement concrete Pavement with some cracks. The crack is reflected in the same pattern on bituminous Pavement.

1.7 Raveling

The dislodgement is the loss of relating between the aggregate patches and the asphalt binder. The summations are occasionally carpeted with dust patches that lack cling. This will make the total bind with the dust rather than the binder.

1.8 Longitudinal and Transverse Cracking Torture

This torture can be considered as either structural or environmental torture. The longitudinal cracks are formed resembling to the pavement alignment or the center line of the Pavement.

This is a fatigue cracking. Then, the cracking occurs in the direction of business inflow. The transverse cracking is formed vertically to the pavement center line.

2. Structural Failure of Bituminous Pavement Structures

The wheel cargo operation constant over the Pavement will form in the structural failure. Structural failures made the structural change more clear and measurable.

The structural is distributed as the physical failures planted on the Pavement and the sub-base.

- Alligator Cracking or collude to crack

- Depressions

- Corrugations

- Shoving

- Potholes

- Rutting

- Swelling

2.1 Alligator Cracking or Collude to Crack

Alligator cracking is the common type of failure of bituminous Pavement. Alligator cracking is observed only in areas that have repeated business lading. Alligator cracking is one of the major structural torture.

This torture is latterly accompanied by rutting. A series of connected cracks are observed due to similar torture.

2.2 Depressions

Depressions in flexible pavements are a veritably common torture plant in parking lot construction as well as by overlays. The foundation soil agreement can cause this depression due to nonstop lading.

Different inflexibility situations are considered for the depression in the flexible Pavement constructed for airport purposes.

2.3 Corrugations

The grooves are torture seen in the Pavement at regular intervals in the form of crests and denes. The crests form of grooves will be vertical to the business direction.

Unstable Pavement plus business will produce similar torture. Where the business starts and stops, this torture is observed.

2.4 Shoving

A form of plastic movement that’s seen in the form of the surge is called shoving torture. These are also observed vertical to the direction of the business.

2.5 Potholes

When there’s a lack of list between face course and underpinning sub caste, some portion of face course loses up accoutrements creating patches and potholes.

Slippage cracking is one form of potholes type of failure. Lack of high fleece or method fleece between two layers is the primary reason behind this type of failure.

2.6 Rutting

The depression formed in the face is called rutting. Confirmation of routines falls in this type of failure. A pattern is a depression or groove worn into a road by the trip of the bus.

Repeated operation of cargo along the same wheel path forming longitudinal routines. Wearing of the face course along the wheel path forms shallow routines.

2.7 Swelling

These are torture that long and gradational surge. These can be ten bases long. The swelling torture is characterized by the upward bulge in the pavement face.

Face cracking is the coming series of torture that’s seen after swelling. The main reason behind swelling in flexible Pavement is the frost action in the subgrade. The Constructor.

What is Bituminous Road?

Roads with bituminous pavement construction or cement concreting face, showcasing the layers of bitumen road, are called surfaced roads.

Bitumen road construction, a key aspect of bituminous work, consists of varied ways like medication of base course, operation of a very thin surface applied over a bituminous pavement to make it impervious, placement of bituminous blend, rolling, and check for quality etc. which are bandied.

Bituminous and other temporary results are feathers of construction that are only suitable for use on veritably low-business expressways.

Chip sealing ways, thin membrane surfacing, and Otta sealing exemplify bituminous face options. These are each more generally employed as sealing fleeces or homestretches than as full road shells.

Construction of Bitumen Pavement

Bitumen road construction consists of the varied way like medication of base course, operation of bituminous fleece, placement of bituminous blend, rolling and check for quality, etc., which are bandied.

Steps in Bituminous Road Construction

Following are the colourful way in bituminous road construction similar as:

- Preparation of the living base course sub caste

- Operation of Tuck Coat

- Preparation and placing of Premix

- Rolling

- Quality control of bituminous concrete construction

- Finished face

Step.1. Preparation of the Living Base Course Sub Caste

The being face is prepared by removing the potholes. If the being pavement is extremely way, a bituminous levelling course of acceptable consistency is handed to get a bituminous concrete face course on a binder course rather than directly laying it on a WBM.

Step.2. Operation of Tuck Coat

It’s desirable to lay AC sub caste over a bituminous base or binder course. A tuck fleece of bitumen is applied at6.0 to7.5 kg per 10sq. M area; this volume may be increased to7.5 to 10 kg for the non-bituminous base.

Step.3. Preparation and Placing of Premix

The premix is prepared in a hot blend factory of a needed capacity with the asked quality control. The bitumen may be hotted up to 150 – 177 dg C, and the aggregate temperature shouldn’t differ by over 14 deg C from the binder temperature.

The camber and thus the consistency of the sub caste are directly vindicated. The control of the temperatures during the mixing and the contraction is of great significance in the strength of the performing pavement structure.

Step.4. Rolling

An after the mixing, it’s placed on the base course is completely compacted by rolling at speed not further than 5 km per hour.

The original or break down rolling is done by 8 to 12 tonnes comber, and the intermediate rolling is done with a fixed wheel curvaceous comber of 15 to 30 tonnes having a tyre pressure of 7 kg per sq. cm. the bus of the comber is kept damp with water.

The number of passes needed depends on the consistency of the sub caste. In warm rainfall, rolling on a coming day helps increase the original rolling viscosity wasn’t acceptable. The final rolling or finishing is done by 8 to 10 tone tandem comber.

Step.5. Quality Control of Bituminous Concrete Construction

The routine checks are carried out to ensure the quality of the performing pavement admixture and the pavement face.

Periodical checks are made for:

- Aggregate grading

- Grade of bitumen

- Temperature of aggregate

- The temperature of the paving blend during mixing and contraction.

Marshall Tests are also conducted. The variation in the consistency allowed is 6 mm per4.5 m length of construction.

Step.6. Finished Face

0 m straight edges should check the AC face. The longitudinal undulations shouldn’t exceed8.0 mm, and the number of undulations advanced than 6.0 mm shouldn’t exceed 10 in a length of 300m. The cross-traffic profile shouldn’t have undulations exceeding4.0 mm.

Advantages of Bituminous Pavement

Following are the several advantages of bituminous Pavement similar as

- A Smooth Lift Face: Bituminous sidewalk and Bituminous Pavement maintain the smoothness because the wear and gash are less in the bitumen road and lower sound emigration.When comparing bitumen vs asphalt, Bituminous roads are leak proof, non-slippery, smooth, and durable. The bituminous layer plays a crucial role in this. Bituminous Pavement is provided with a comfortable road face for the business.

- Gradational Failure: The concrete Pavement shows brittle failures. The distortion and the failure is a gradational process in the bitumen road.

- Quick Form: The repairing of bitumen road is a quick process. They set presto, so they do not waste time returning the path for business.

- Offered Construction: When fund constraint or business estimation problems are faced, this situation helps in carrying out offered construction.

- Life Cost Is Less: The original cost of bituminous Pavement is less as compared to concrete Pavement. Overall conservation costs of bituminous Pavement are less as compared to concrete Pavement.

- Temperature Resistant: Bituminous Pavement has a lower vulnerability to daily and seasonal temperature variations. Advanced resistance to distortion at high pavement temperature.It can the adverse natural goods caused by heavy rain, redundant heat and change in temperature.Life Span: Bituminous roads don’t develop cracks on the face for a long period. Bituminous Pavement has better age resistance parcels.

Disadvantages of Bituminous Pavement

Following are the several disadvantages of bituminous Pavement similar as.

- Bituminous pavements are less durable.

- Bituminous Pavement has low tensile strength.

- The bitumen road will be slick and soft in extreme rainfall and indecorous rainfall conditions.

- In bitumen, present contaminations also prompt the soil; it contains hydrocarbon, which affects the groundwater, i.e. terrain get defiled during preparing blend.

- Still, it affects the performance of the bituminous road; if the bituminous material is used in redundant, then the value for the given blend.

- Clogging of pores and drainage path during construction and service life. More salting-to help snow during downtime season.

- The cost of construction is high during extreme conditions of temperature.

Conclusion of Bituminous Pavement

The surface structure of the Pavement shall have to be improved upon periodically in future as well. Presently, rigid concrete pavements should be preferred over bituminous Pavement due to their high continuity and high strength.

Bituminous roads are leak proof, non-slippery, smooth, and durable. Bituminous Pavement is provided with a comfortable road face for the traffic.

Frequently Asked Questions (FAQ) about Bituminous Pavement

What Is Bituminous Pavement?

Bituminous pavement is a type of road surface made from asphalt, also known as bitumen. It consists of multiple layers including the base, binder, and surface course, each made from different materials to fulfill specific functions.

What Materials Are Used in Bituminous Pavement?

Bituminous pavement is primarily composed of bitumen (asphalt) mixed with various aggregates like sand, gravel, and crushed stone. The mixture is applied in layers to create a flexible and durable road surface.

What Are the Different Layers in Bituminous Pavement?

The main layers in bituminous pavement include:

- Bituminous Base Course: The foundational layer made from mineral aggregates and bitumen.

- Bituminous Binder Course: An intermediate layer that provides additional stability and is made from a mixture of bituminous binder and aggregates.

- Bituminous Concrete Surface Course: The top layer, which provides the final wearing surface and is made from finely graded aggregates mixed with bitumen.

What Are the Common Types of Bituminous Pavement Failures?

Common failures include:

- Bleeding: Excess bitumen causes a glossy, sticky surface.

- Block Cracking: Thermal cracks forming blocks in the pavement.

- Raveling: Loss of aggregate due to poor binder adhesion.

- Potholes: Depressions caused by a lack of adhesion between pavement layers.

- Alligator Cracking: Cracking in a pattern resembling alligator skin, often due to repeated traffic loads.

What Are the Advantages of Bituminous Pavement?

Advantages include a smooth driving surface, quick construction and repair times, lower initial construction costs compared to concrete pavements, and good resistance to temperature variations and water damage.

What Are the Disadvantages of Bituminous Pavement?

Disadvantages include lower durability compared to concrete pavements, susceptibility to damage in extreme weather conditions, and potential environmental concerns due to the presence of hydrocarbons.

How Is Bituminous Pavement Constructed?

Construction involves several steps:

- Preparation of the Base Course: Cleaning and leveling the existing surface.

- Application of Tack Coat: A layer of bitumen is applied to ensure good bonding between layers.

- Preparation and Placing of Premix: Mixing bitumen with aggregates and applying the mix to the prepared base.

- Rolling: Compaction of the bituminous layer using rollers to ensure proper density and smoothness.

- Quality Control: Testing the pavement to ensure it meets specified standards.

What Maintenance Is Required for Bituminous Pavements?

Regular maintenance includes filling cracks, sealing the surface, and addressing any areas of raveling or potholes. Periodic resurfacing may also be required to extend the pavement’s life.

Can Bituminous Pavements Be Recycled?

Yes, bituminous pavements can be recycled. Old pavement material can be reclaimed, processed, and reused in new asphalt mixtures, reducing waste and conserving resources.

How Does Bituminous Pavement Compare to Concrete Pavement?

Bituminous pavements are generally more flexible and quicker to construct than concrete pavements. However, concrete pavements are often preferred for their higher durability and strength. The choice between the two depends on factors such as traffic volume, climate, and budget.